Pilot plants are small-scale processing plants designed to simulate industrial or research processes before large-scale implementation. They are essential for testing technologies, optimizing processes, and validating models before investing in mass production. These plants allow researchers and...

At EDIBON, we reaffirm our commitment to the advancement of clean and renewable energy, with a special focus on green hydrogen as a key driver for a more sustainable future. We are proud to have been selected to equip the first Green Hydrogen Laboratory in the Region of Murcia, a pioneering space...

The shift towards electric vehicles (EVs) has gained considerable momentum worldwide, promising a reduction in greenhouse gas emissions and a path to a more sustainable future. However, as the demand for EVs accelerates, so too does the need for large quantities of essential minerals, such as...

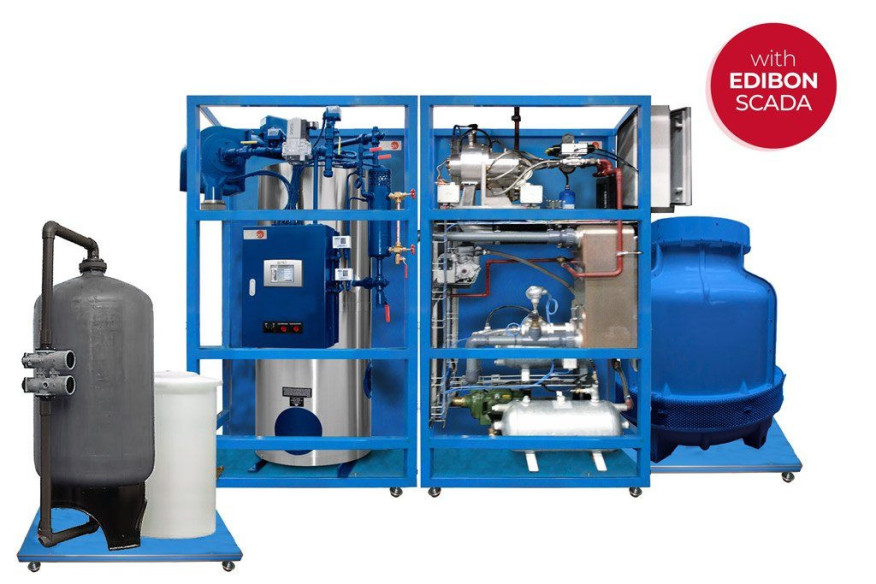

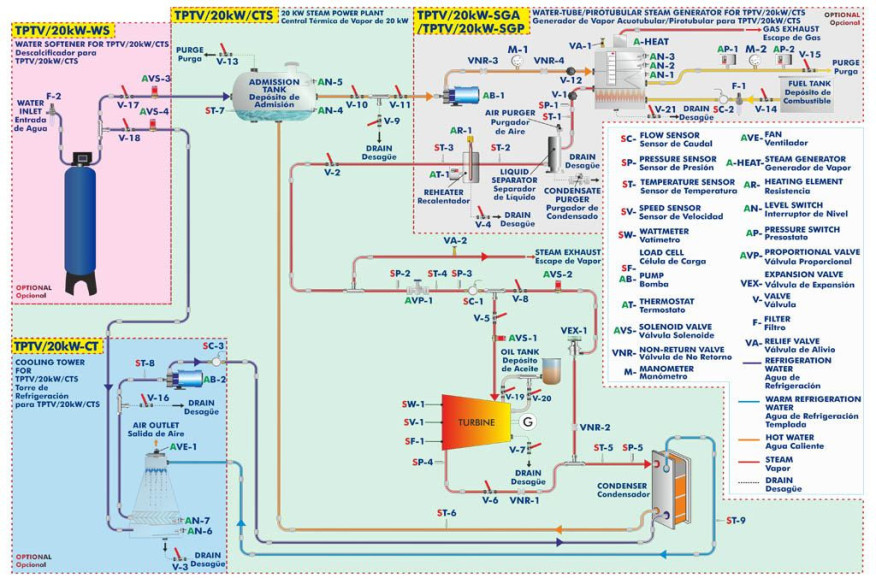

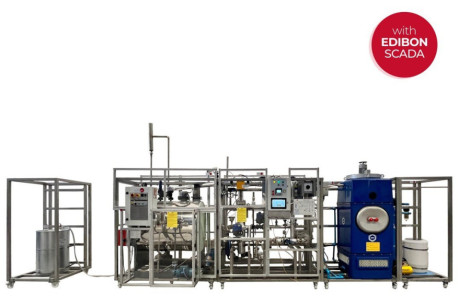

Thermodynamics and thermotechnology are fundamental fields of engineering that play a critical role across various industries, from energy generation to climate control. Understanding these foundational concepts is essential not only for engineers but also for fostering technological innovations...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

In a world where energy demand continues to rise and non-renewable resources are rapidly depleting, the need for sustainable, environmentally friendly solutions has never been more urgent. The circular economy and the use of organic biomass to produce biofuels are emerging as key answers to...

We are excited to celebrate the publication of the article by Prof. Dr. Nina Penkova titled "Performance of Diffusion Absorption Refrigerators with Variable Input Power" The study explores how absorption refrigerators, which utilize waste or solar energy for heating and cooling, can operate...

ダイレクトエアキャプチャー (DAC) は、液体溶媒や固体吸収剤との化学反応を利用して空気中のCO₂を直接除去する革新的な技術です。コストの高さやエネルギー消費といった課題はあるものの、DACは大気中のCO₂濃度を減らし、気候変動を緩和する潜在的な解決策を提供します。DACの研究開発を継続することが、その実現可能性と効果を向上させるために重要です。

クッキーの設定

クッキーの設定