EBEC コンピューター制御バイオエタノールプロセス実験装置

革新的なシステム

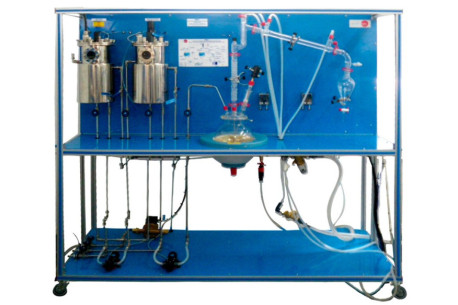

The Computer Controlled Bioethanol Process Unit "EBEC" has been designed to study and control the bioethanol production process on a laboratory scale.

拡張

研究室

関連ニュース

概要

The Computer Controlled Bioethanol Process Unit, "EBEC", has been designed to study and control the bioethanol production process on a laboratory scale. This unit allows to monitor and examine all the important processes, from liquefaction and saccharification of the raw materials, to the conversion of sugar into ethanol and distillation.

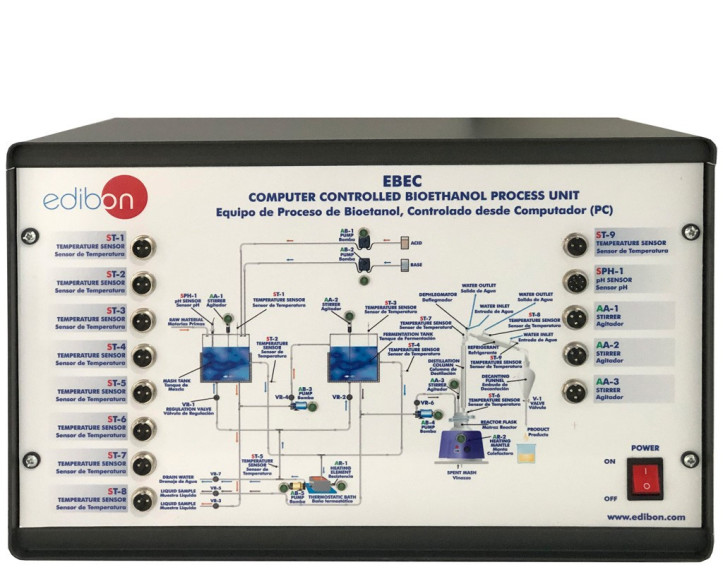

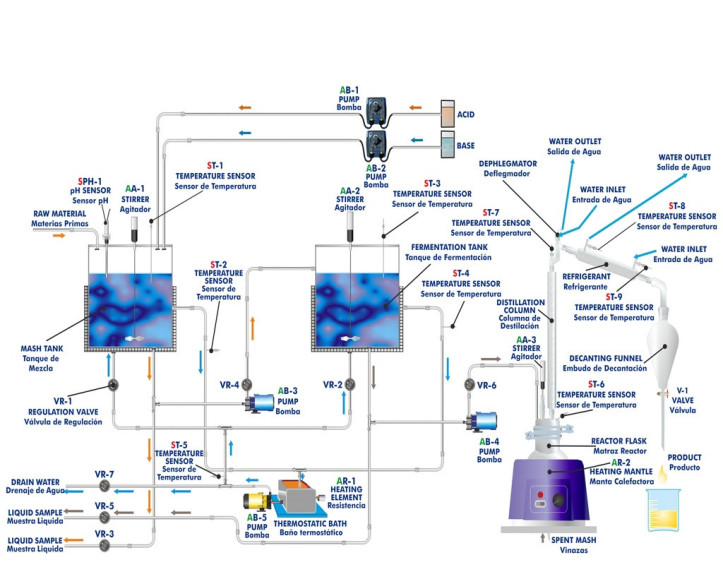

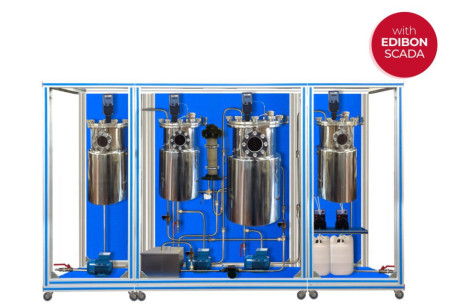

The unit consists of three main components: a mash tank, a fermentation tank and a distillation unit.

All vessels, valves and other accessories in contact with the process materials (except the distillation unit) are made of stainless steel. The distillation unit is made of borosilicate glass. Sight glasses are made of Neoceram glass.

The mash tank includes an inlet at its upper cover for filling water, starch and enzymes. Its base is slightly inclined towards a port for draining the solution or pumping it into the fermentation tank. During the mashing process the starch of the raw materials is turned into glucose. The addition of the alpha-amylase enzyme enables the liquefaction of the starch slurry. Subsequently, saccharification starts by adding the glucoamylase enzyme. A temperature sensor and a pH sensor measure the properties of the mixture in the tank. The pH value is adjusted by adding acid and base solutions, with an acid/base circuit system.

After saccharification the mash is pumped into the fermentation tank. The fermentation tank base is inclined slightly towards a port for draining the solution or pumping it into the distillation unit. The fermentation process takes place after adding yeast, producing ethanol and CO2. A sensor measures the temperature of the mixture in the tank

Both tanks are heated indirectly with hot water through a jacket and stirred constantly. Besides, they are equipped with a sight glass so that the processes can be observed and monitored. Two temperature sensors, located at the outlet of the tanks' jacket, work with the PID controller to maintain the desired temperature inside.

The mash tank and the fermentation tank are thermally controlled by hot water, which is heated by a system consisting of a thermostatic bath and a pump. An additional temperature sensor is located in the thermostatic bath.

After the fermentation process, the preparation is pumped into the distillation unit. It contains a heating mantle, a stirrer, a distillation column, a cold finger (dephlegmator), a condenser and a decanting funnel. Four temperature sensors are located at different points of the distillation unit.

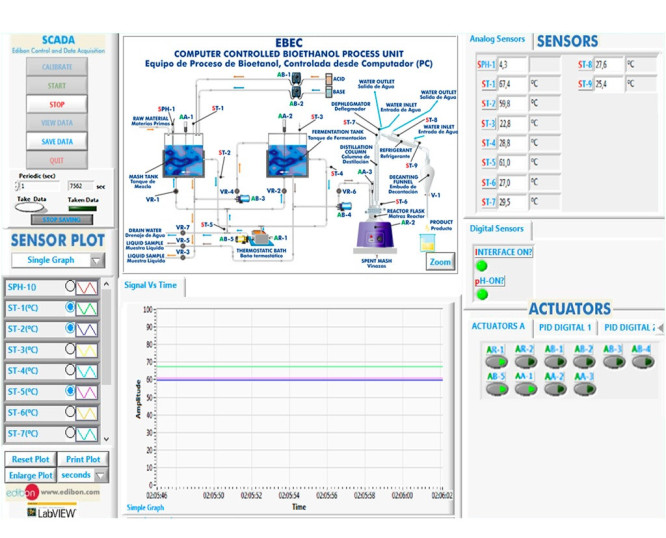

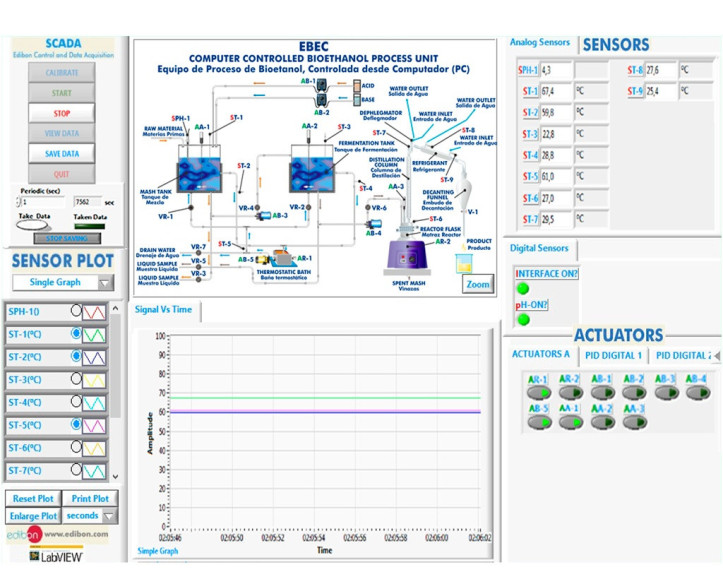

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Familiarization with the individual steps required for bioethanol production.

- Familiarization with the plant components required for bioethanol production.

- Study of the effect of temperature on bioethanol purity.

- Study of the effect of pH on bioethanol yield.

- Study of the effect of mashing time on bioethanol yield.

- Study of the effect of fermentation time on bioethanol yield.

- Study of the use of different raw materials to produce bioethanol.

- Study of the effect of adding different types of yeast to the fermentation.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EBEC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EBEC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

利用可能な類似の機器

補完的な機器

コンピューター(PC)およびタッチスクリーンで制御される60リットルの半連続遠心分離器

コンピューター(PC)およびタッチスクリーンで制御される1000リットルの半連続遠心分離器

バイオエタノールプロセス実験装置

バイオガス処理プラント、コンピュータとタッチスクリーン制御 (PC)

コンピュータ制御のバイオガスプロセスユニット

バイオガスプロセス実験装置

コンピューター制御バイオディーゼルプロセス実験装置

バイオディーゼルプロセス実験装置

コンピューター制御バイオマスプロセス実験装置

バイオマスプロセス実験装置

品質

アフターサービス

クッキーの設定

クッキーの設定