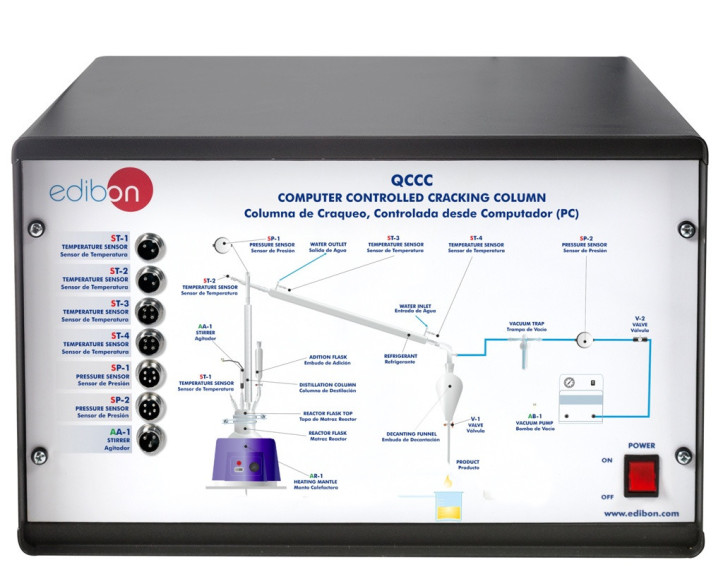

QCCC クラッキング塔、コンピュータ制御(PC)

革新的なシステム

The Computer Controlled Cracking Column, "QCCC", for cracking and distilling oil is a complete lab tool that allows to the students to carry out a cracking reaction, and the study and the control of different variables that condition it.

拡張

研究室

関連ニュース

概要

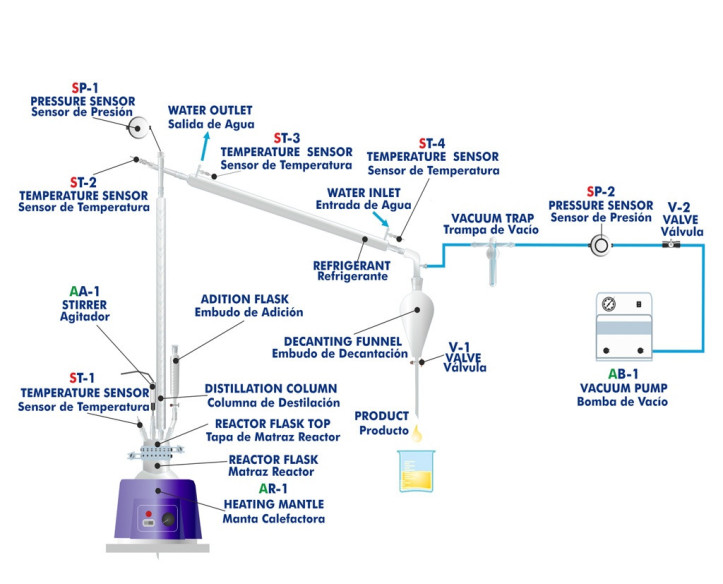

The Computer Controlled Cracking Column, "QCCC", for cracking and distilling oil is a complete lab tool that allows to the students to carry out a cracking reaction, and the study and the control of different variables that condition it. Also, the production cycle will be completed by means of a separation, purification and analysis of the obtained products in that cracking reaction.

This unit is controlled from a computer. That allows a register of temperature and pressure data and the control of the cracking and distillation processes. Control software is easy and intuitive.

It consists of a glass body, perfectly fixed to an aluminum structure, which allows its handling with complete security, and several systems that allow to control the reaction: stirring, cooling, emptying and heating.

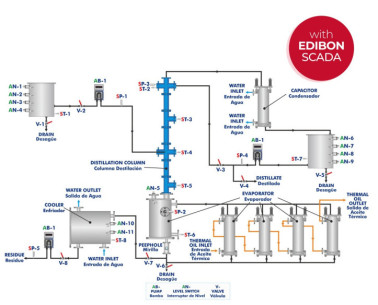

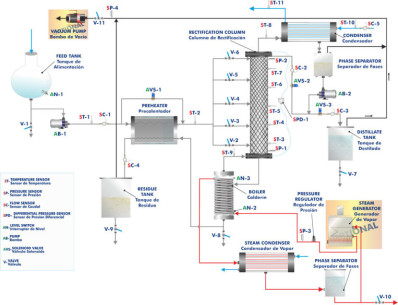

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Carry out cracking reactions.

- Influence of the temperature in the Ricinoleic Acid cracking reaction (gradual increment of temperature).

- Influence of the temperature in the Ricinoleic Acid cracking reaction (sudden increment of temperature).

- Influence of the pressure in the Ricinoleic Acid pyrolysis reaction (working pressure too low).

- Influence of pressure in the Ricinoleic Acid pyrolysis reaction (low working pressure).

- Work with different heating gradients, regulated through the computer.

- Work with different pressures, regulated through the computer.

- Pitch as a catalyst.

- Simple distillation.

- Separation in its components of the product mixture of cracking.

- Heptanal purification.

- Undecylenic acid purification.

- Application of samples on TLC plates.

- Thin layer chromatography plates analysis.

- Study of several parameters that influence the analysis by thin layer chromatography.

- Other simple practices as calibration of instruments, preparation of samples, etc.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Cleaning the system.

- Monogram of pressure.

Other possibilities to be done with this unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QCCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QCCC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

補完的な機器

腐食性溶剤の12 l/hの回収のための蒸留、コンピューター(PC)とタッチスクリーンから制御

Advanced Computer Controlled Continuous Destillation Unit

コンピューター制御連続蒸留装置

連続蒸留装置

コンピューター制御バッチ式蒸留装置

バッチ式蒸留装置

品質

アフターサービス

クッキーの設定

クッキーの設定