PDFDC コンピューター制御排水・漏水タンク

革新的なシステム

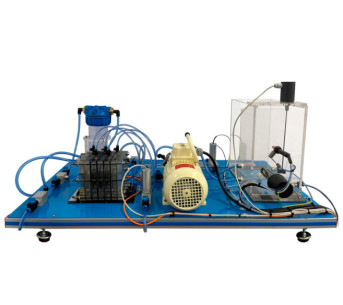

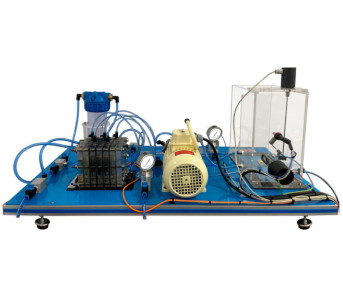

The Computer Controlled Drainage and Seepage Tank, "PDFDC", has been designed by EDIBON for the practical demonstration, visualization and experimental study of the flow through permeable media and flows in subsoil.

拡張

研究室

関連ニュース

概要

The Computer Controlled Drainage and Seepage Tank, "PDFDC", has been designed by EDIBON for the practical demonstration, visualization and experimental study of the flow through permeable media and flows in subsoil.

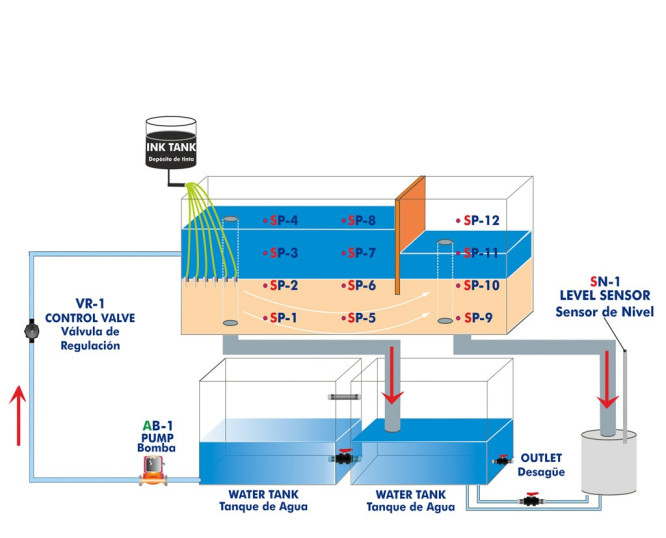

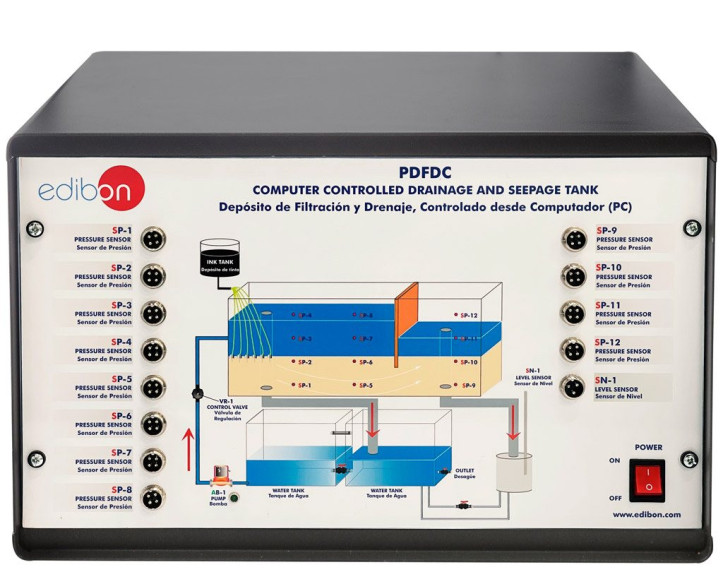

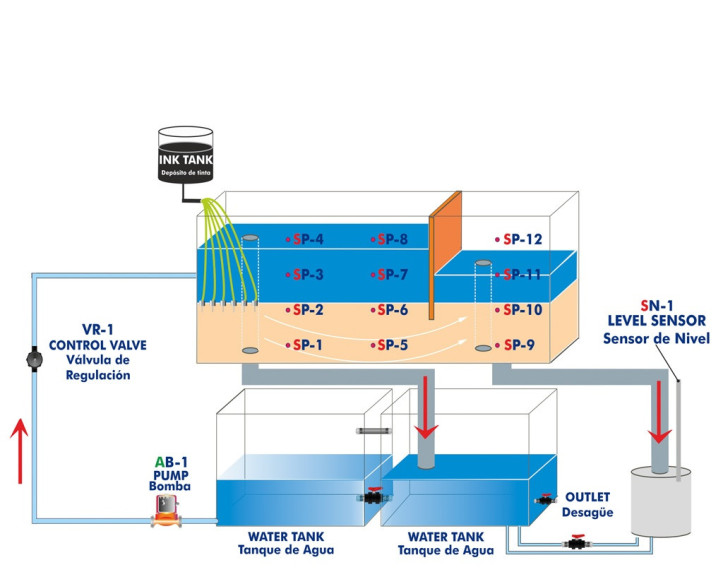

The "PDFDC" basically consist of a tank (soils container) to contain the sand, lower water tanks, a pump for the water flow, pressure sensors, a dye injection system with dye injection needles.

The soils container consists on a rectangular tank, with back side in aluminium and front side in methacrylate to see the flow lines. It contains the wet sand which must be collected or sampled by the student.

The sand distribution in the tank must be according to the experiment configuration which we want to carry out. For it, there are overflow pipes to be able to put them at different heights, and going up and down the tubes.

The outlet tubes of the overflow pipes make easier the water falling to the tank which has a level switch and a key in order to the lower water tanks go out. The water flow can be measured.

A set of typical models is included: a sheet pile wall, two mesh gates and a mobile accessory for pressure measurement, for pressure fall measurements tests, phreatic layer tests, earth dam, etc.

To check the flow lines, there is a dye injection system. This system has a dye vessel and injection needles through where the liquid flows and which are inserted in the sand in the tank, close to the methacrylate side for the flow visualization lines.

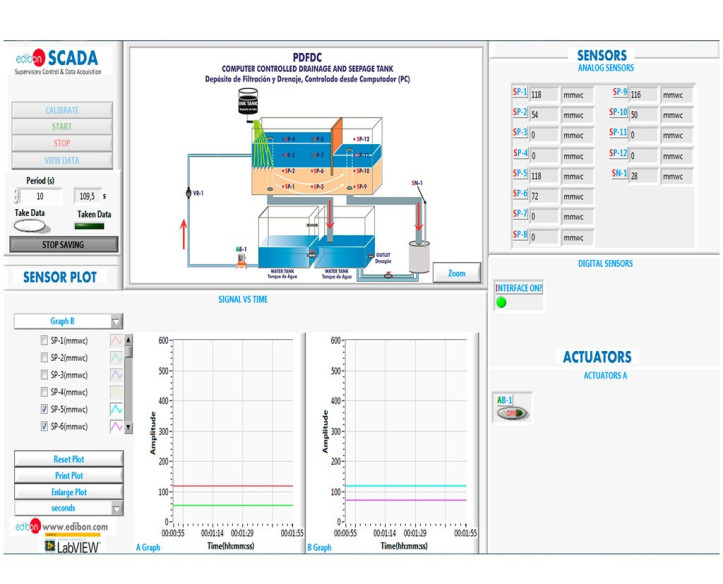

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Flow net construction.

- Flow line visualisation.

- Verification of Darcy´s Law.

- Comparison of experimental results with analytical solutions.

- To determine seepage rates.

- Seepage through an earth dam.

- Seepage underneath a sheet pile wall.

- Control of seepage through permeable soils by sub-soil drainage.

- To reduce uplift pressure and lateral thrust by drainage.

- Distribution of uplift pressure on hydraulic structures.

- Behaviour and formation of "quicksands".

- To drain an excavation site using wells

- Stability of an earth dam.

- Comparison of permeability according to the grain size.

- Sheet pile wall:

- Study of the soil permeability.

- Flow lines visualization.

- Calculation of the equipotential lines.

- Pressures distribution.

- Permeability of the phreatic layer:

- Study of the soil permeability.

- Flow lines visualization.

- Calculation of the equipotential lines.

- Measurement of the infiltration speed.

- Verification of the Law of Darcy.

- Flow through an earth dam:

- Study of the soil permeability.

- Flow lines visualization.

- Calculation of the equipotential lines.

- Pressures distribution.

- Effects of the layer inclination.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PDFDC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PDFDC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

利用可能な類似の機器

補完的な機器

コンピューター(PC)およびタッチスクリーンで制御される60リットルの半連続遠心分離器

コンピューター(PC)およびタッチスクリーンで制御される1000リットルの半連続遠心分離器

コンピューター制御連続バッチ式フィルター実験装置

連続バッチ式フィルター実験装置

コンピューター制御プレート&フレーム圧濾器

コンピューター制御深層ろ過実験装置

深層ろ過実験装置

沈殿学習装置

コンピューター制御沈殿タンク

沈殿タンク

排水・漏水タンク

コンピューター制御逆浸透・限外ろ過装置

品質

アフターサービス

クッキーの設定

クッキーの設定