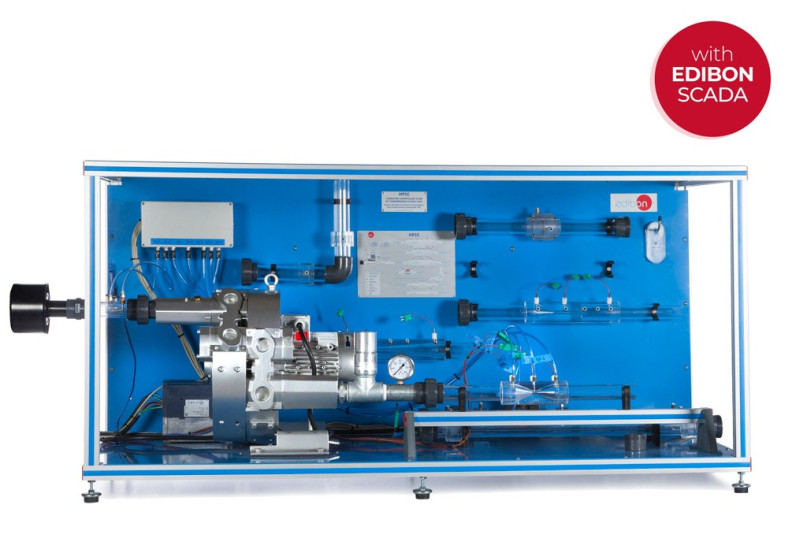

HFCC コンピューター制御圧縮流体流動実験装置

革新的なシステム

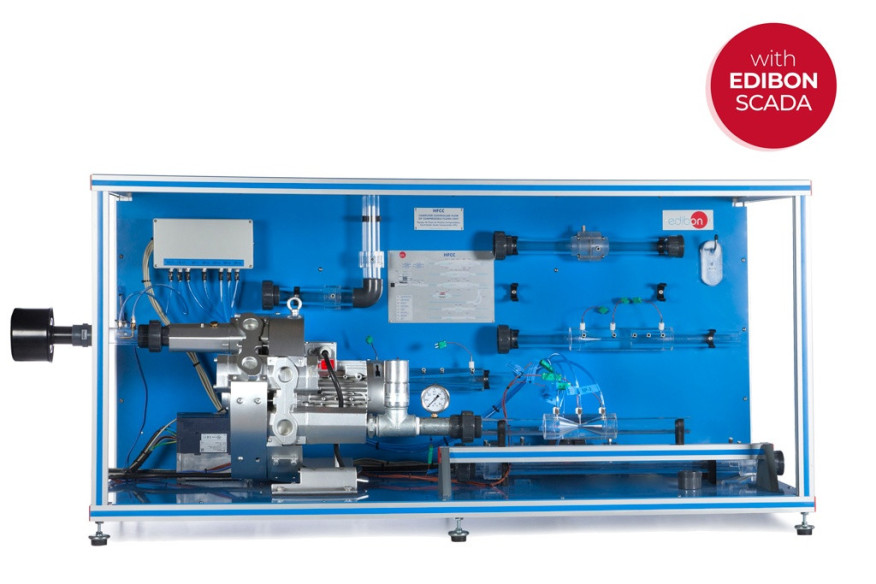

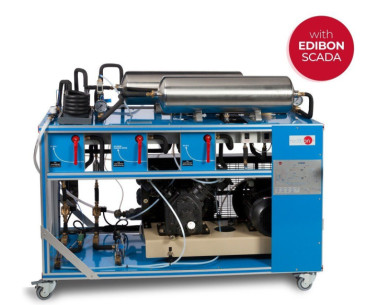

The Computer Controlled Flow of Compressible Fluids Unit, "HFCC", allows to study the variation of pressure and density, the speeds of the fluid, the different fluctuations that the fluid presents when fluids across different sections in a pipe, and the thermodynamics and fluid dynamics characteristics that the fluid has.

拡張

研究室

関連ニュース

概要

The Computer Controlled Flow of Compressible Fluids Unit, "HFCC", allows to study the variation of pressure and density, the speeds of the fluid, the different fluctuations that the fluid presents when fluids across different sections in a pipe, and the thermodynamics and fluid dynamics characteristics that the fluid has.

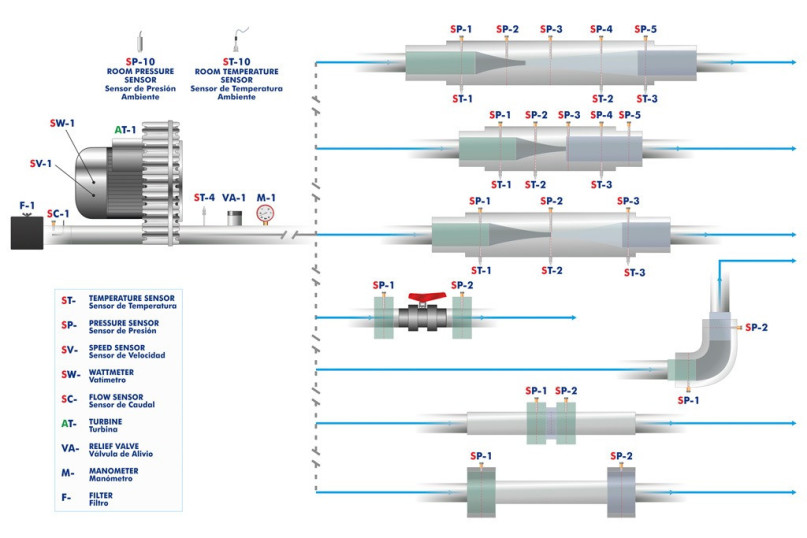

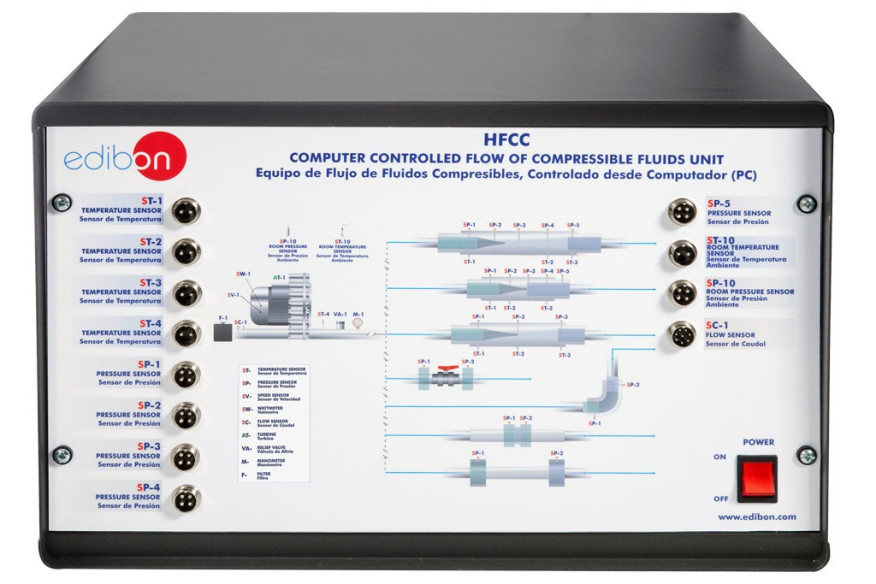

The air enters by the intake tube, where there is a dust filter. It provides a current free of particles in suspension and other substances dragged by air.

After the filter, the flow is measured with a Pitot tube installed in the pipe.

After the air is impelled by the turbine, it leaves this device through a straight pipe that includes a safety relief valve, a thermocouple that measures the outlet temperature and a static pressure manometer that measures pressure inthe wall of the tube.

There is a quick-release fitting at the outlet of the exhaust pipe to connect the different accessories of the unit.

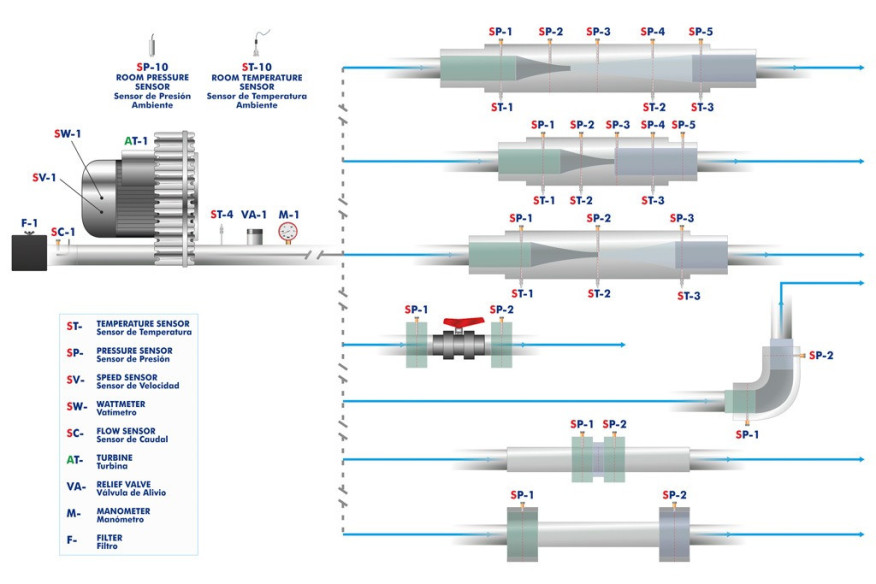

This unit allows for studying different flow situations:

- Abrupt widening.

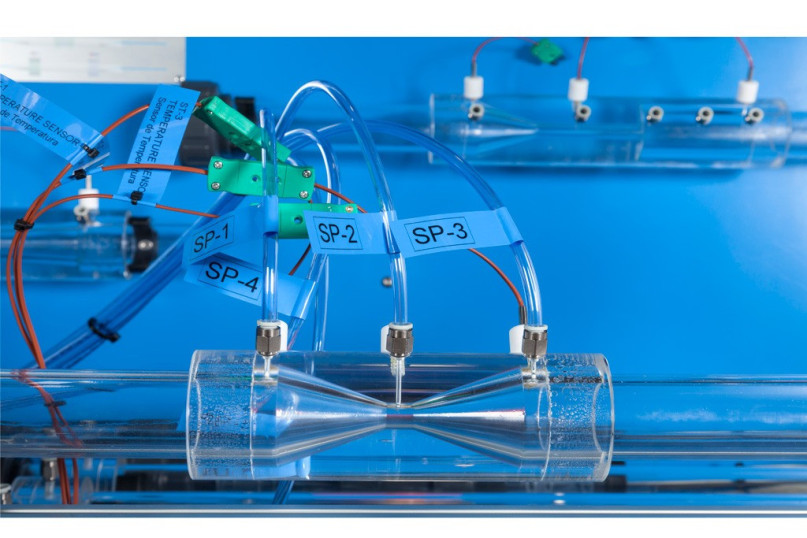

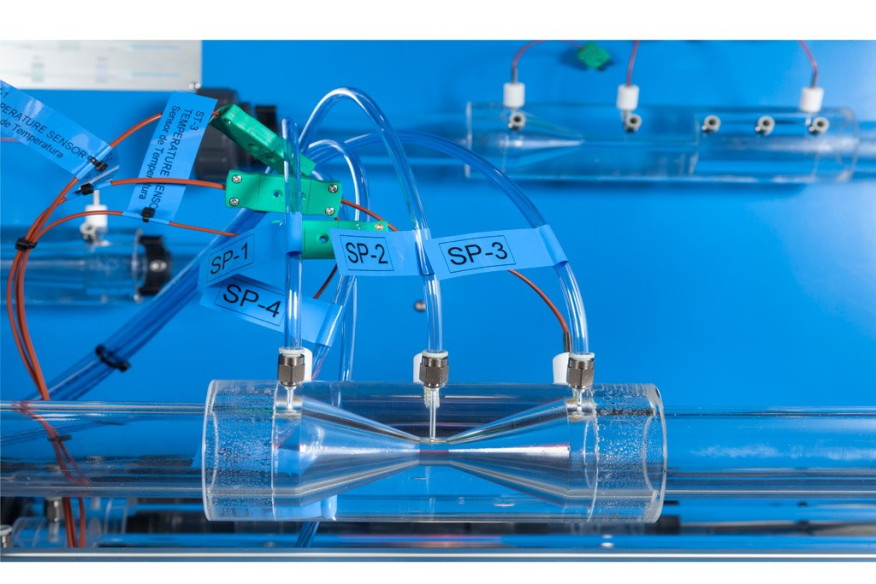

- Venturi tube.

- Ball valve.

- Bend of 90°.

- Orifice plate.

- Straights pipes sections.

- Laval nozzle.

To analyze the different parameters studied, all accessories have the connections for the instrumentation included.

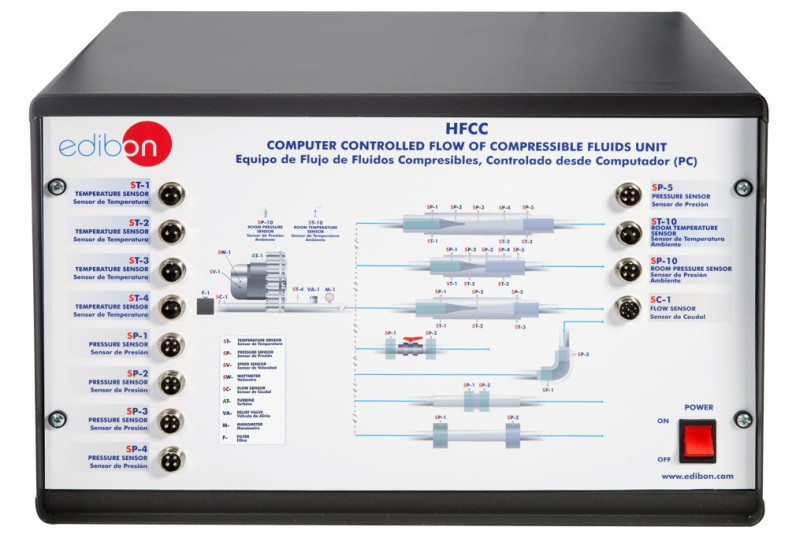

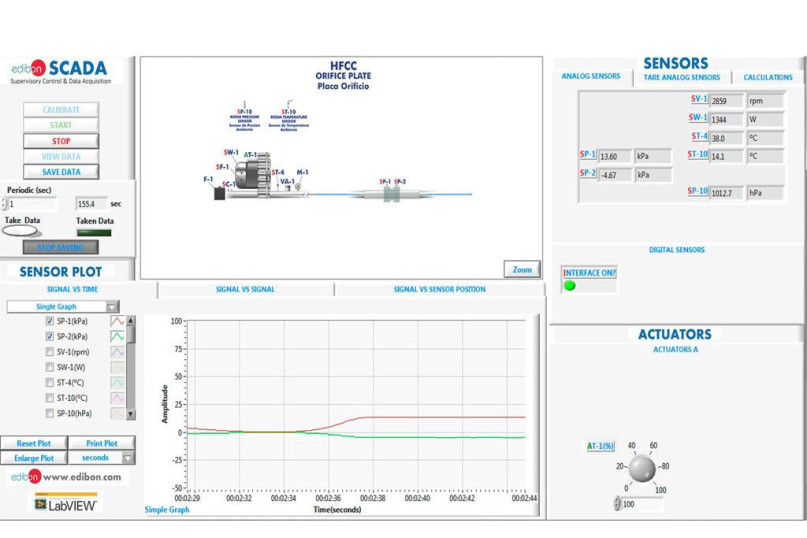

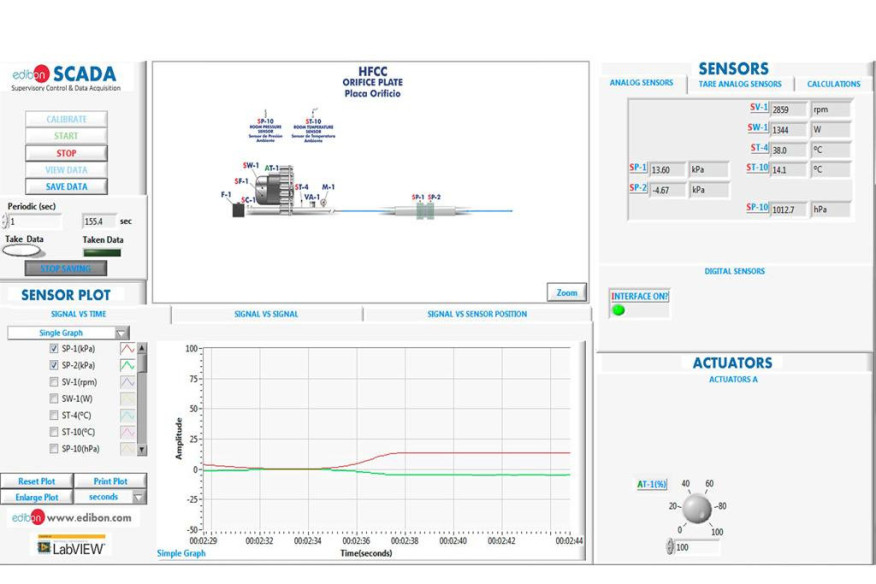

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + aControl Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Determination of pressure drops in straight pipe sections.

- Study of the relationship between velocity and pressure drops in a straight pipe section.

- Determination of pressure drops in a pipe with a bend of 90º.

- Determination of pressure drops in an abrupt widening.

- Determination of pressure drops in a Venturi tube.

- Introduction to supersonic flow in convergent-divergent geometry nozzles.

- Determination of pressure drops through an orifice plate with different interchangeable sections.

- Determination of the mass flow rate through an orifice plate with different interchangeable sections.

- Determination of the characteristic curve of the compressor with the ball valve.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Study of pressure recovery after an abrupt widening.

- Friction coefficient change with Reynolds number.

- Study of the friction coefficient for compressible flow.

- Determination of the mass flow with the study sections.

- Use of the energy balance in the compressor.

- Study of the characteristics of the compressor: pressure, flow, efficiency and power.

- Observing the generation of shock waves inside a Laval nozzle.

- Determination of the air pressure in a convergent-divergent section.

- Study of the compressibility effect on the fluid equations.

- Determination of the speed of sound in the air.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the HFCC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the HFCC unit process.

- Several other exercises can be done and designed by the user.

補完的な機器

コンピューター制御レシプロコンプレッサー

コンピューター制御2段式コンプレッサー試験装置

品質

アフターサービス

クッキーの設定

クッキーの設定