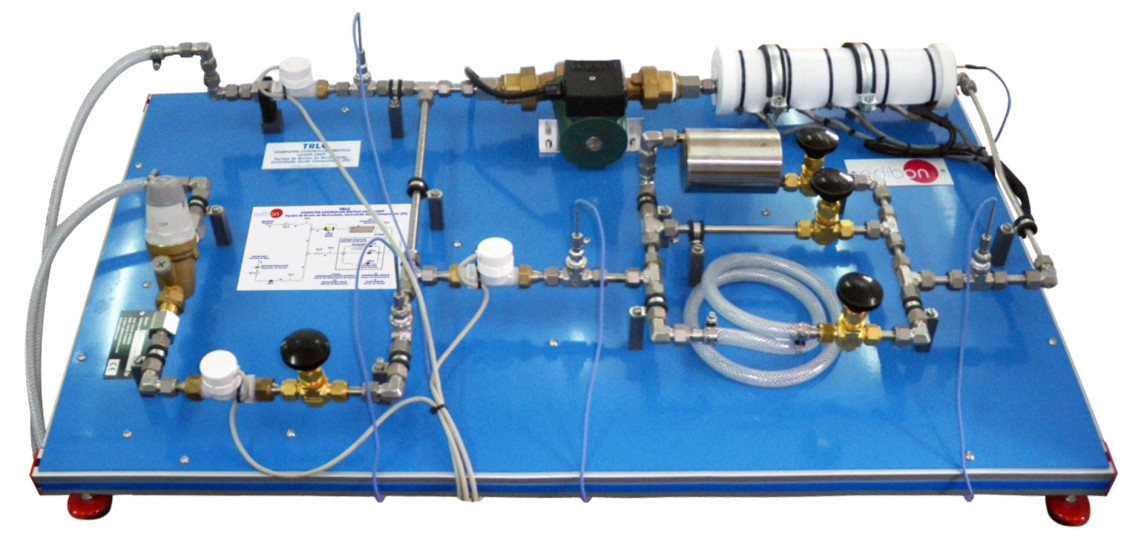

TRLC コンピューター制御循環ループ実験装置

革新的なシステム

The Computer Controlled Recycle Loops Unit, "TRLC", has been designed to demonstrate, both visually and experimentally, what a recycleloop is and how it works.

拡張

研究室

関連ニュース

概要

The Computer Controlled Recycle Loops Unit, "TRLC", has been designed to demonstrate, both visually and experimentally, what a recycleloop is and how it works. It has many teaching applications, among them the performance of mass and energy balances under stable andunstable state conditions.

In this unit an inlet water flow is thermally conditioned in a recycle loop to obtain an outlet water flow that fits the desired conditions.

The unit consists of a tube that carries water from the cold water supply to a drain and a loop connected between the supply and the drainconnections. This recycle loop includes a pump and a heating element to increase the water temperature inside the loop.

Different volumes of the recycle loop can be selected by just opening the corresponding valve.

The residence time of each configuration can be studied. The loop flow variation has important didactic properties. The recycle loop isregulated through that variation.

The water temperature at the inlet, outlet and inside the loop are measured with temperature sensors. The water flows in the correspondingpoints are measured with flow sensors.

Mass and energy balances in different points of the circuit can be determined with the data obtained. The experimental results arecompared with the theoretical one using the software.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + aControl Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, forcontrolling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Understanding the meaning of Water Recycle Loop.

Mass balances of steady state:

- Mass balance in the recycle loop in stationary regime withdifferent water proportion in recirculation and different loops.

Heat balances of unsteady state:

- Determination of the recycle loop system response faced, whenthe heating element is switched on, at different flow rates anddifferent loops.

- Determination of the recycle loop system response faced, whenthe heating element is switched off, at different flow rates anddifferent loops.

Heat balances of steady state:

- Thermal balance in the recycle loop in stationary regime withdifferent water proportions in recirculation and different loops.

Additional practical possibilities:

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

Mass balances of steady state:

- Demonstrating that whatever the recycle rate, the inlet flow rateequals the outlet flow rate.

Heat balances of unsteady state:

- Study of the effect of change the inlet flow.

- Study of the effect of recycle with no through flow.

Heat balances of steady state:

- Checking the variation of the outlet temperature, with theheating element switched on and a fixed water flow at the inlet,caused by different recycled flow.

- Determination of the heat quantity absorbed in the recycle loop.

- Use of the steady flow energy equation for the overall system.

- Use of the steady flow energy equation for different points ofthe system.

- Study of the system response when the recycle flow is changed.

- Study of the system response when the inlet-outlet flow ischanged.

- Study of the system response when the recycle volume ischanged.

- Study of the system response when the heating element power ischanged.

Other possibilities to be done with this Unit:

- Many students view results simultaneously.To view all results in real time in the classroom by means of aprojector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control.This unit allows intrinsically and/or extrinsically to change thespan, gains. Proportional, integral, derivative parameters, etc,in real time.

- The Computer Control System with SCADA and PID Controlallow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic,and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industrieseven to other Technical Education Institutions.

- Control of the TRLC unit process through the control interfacebox without the computer.

- Visualization of all the sensors values used in the TRLC unitprocess.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

利用可能な類似の機器

補完的な機器

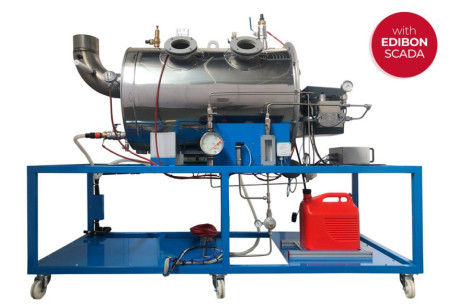

コンピューター制御燃焼実験室装置

熱拡散演習装置

コンピューター制御理想気体膨脹プロセス実験装置

カロリメーターポンプ

コンピューター制御分離・調整熱量計

コンピューター制御Marcetボイラーユニット

Computer Controlled Temperature Measurement Unit

温度測定装置

温度測定演習装置

コンピューター制御気体律実験装置(ボイル&シャルルの法則)

循環ループ実験装置

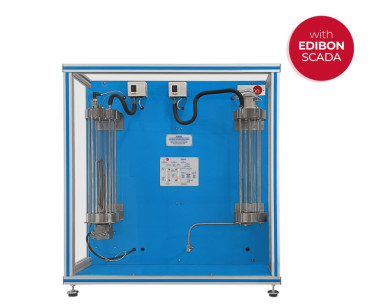

コンピューター制御飽和蒸気圧実験装置

品質

アフターサービス

クッキーの設定

クッキーの設定