RDC コンピューター制御指導用カッテージチーズ製造装置

革新的なシステム

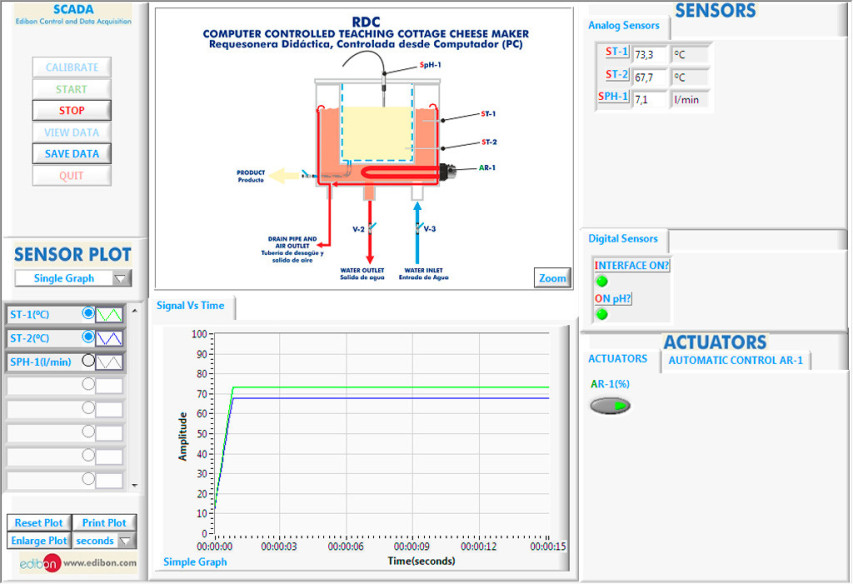

The Computer Controlled Teaching Cottage Cheese Maker, "RDC", is a unit made of stainless steel AISI 304 with a cover at the top. The tank receives milk the bacteria culture and others additives and temperature in the tank increases. This process produces the precipitation of the proteins of the milk and curd is formed.

拡張

研究室

関連ニュース

概要

The Computer Controlled Teaching Cottage Cheese Maker, "RDC", is a unit made of stainless steel AISI 304 with a cover at the top. The tank receives milk the bacteria culture and others additives and temperature in the tank increases. This process produces the precipitation of the proteins of the milk and curd is formed.

The unit has an insulating wall made of stone wool and a water jacket. The function of the jacket is the increment of the temperature for the production of curd and the refrigeration of the unit.

The unit includes two valves (for the water inlet and the water outlet) to fill and empty the jacket with water, and a drain pipe and air outlet to remove air and steam.

The water jacket includes a computer controlled heating element, a temperature sensor and a level switch to guarantee a specific water level inside of jacket.

The temperature and pH of the whey and curd is controlled during the process by a temperature sensor and a pH sensor. A valve situated in the lower side of the tank allows to drain the whey and curd.

The process control is done from the computer using EDIBON control software. This software will allow an automatic control (PID) of the jacket water temperature with the heating element.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Obtainment of whey.

- Obtainment of cottage cheese.

- Measurement of the cottage cheese acidity.

- Determination of the efficiency of the cottage cheese.

- Obtainment of cottage cheese by the traditional process.

- Elaboration of cottage cheese (no traditional process).

- Comparison of the study of acidity in different cottage cheese.

- Determination of the proteins concentration.

- Sensors calibration.

より実用的な練習をして、ユニットを完成させる

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the RDC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the RDC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

補完的な機器

指導用クリーム分離装置

コンピューター制御指導用バター製造装置

指導用バター製造装置

UHTユニット、コンピュータ制御およびタッチスクリーン

コンピューター制御自立型低温殺菌指導装置

コンピューター制御実験室用低温殺菌装置

コンピューター制御凝固指導用タンク

コンピューター制御指導用チーズ垂直型加圧装置

チーズ作り用オランダ風チーズタンク(最大50リットル)

コンピューター制御指導用ヨーグルト定温器

コンピューター制御チーズバット

品質

アフターサービス

クッキーの設定

クッキーの設定