TBMC75 75 kW用コンピュータ制御テストベンチ

革新的なシステム

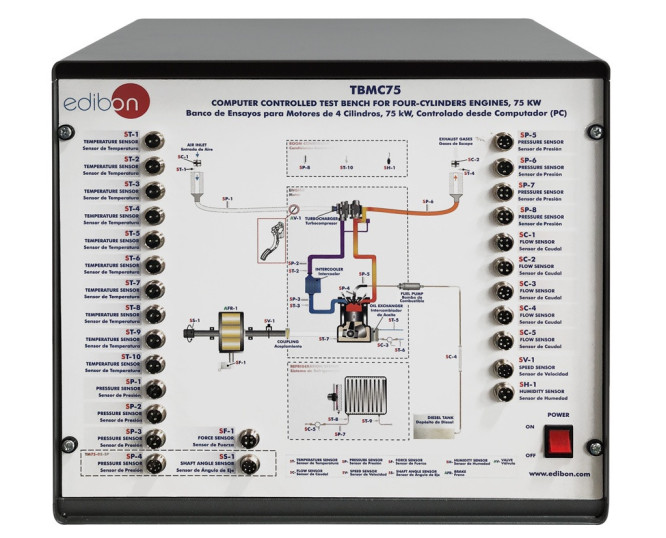

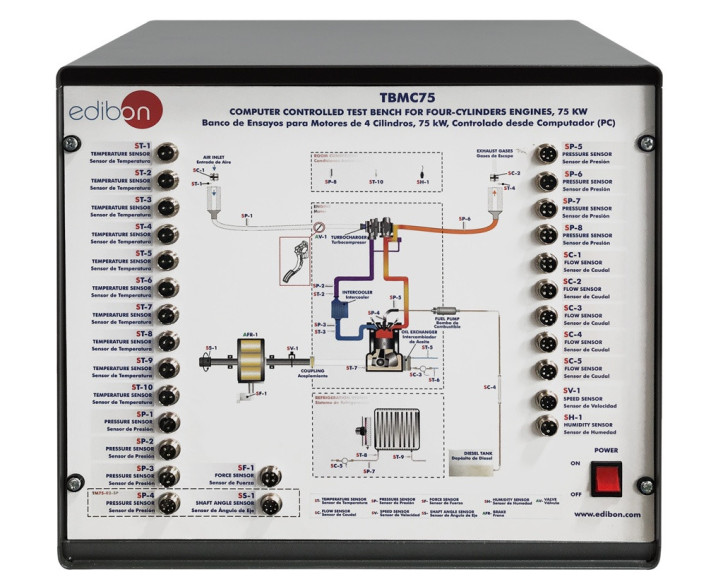

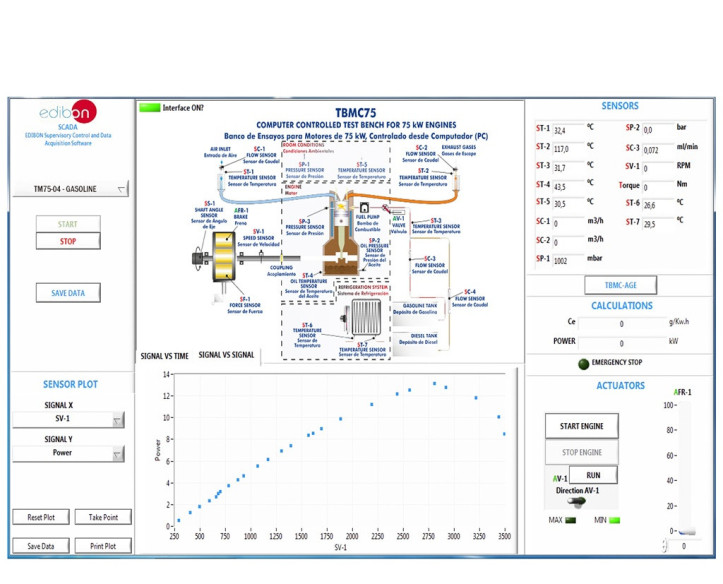

The Computer Controlled Test Bench for Four Cylinders Engines, 75 kW, "TBMC75", designed by EDIBON, is a teaching unit to test internal combustion engines of up to 75 kW.

拡張

研究室

関連ニュース

概要

The Computer Controlled Test Bench for Four Cylinders Engines, 75 kW, "TBMC75", designed by EDIBON, is a teaching unit to test internal combustion engines of up to 75 kW.

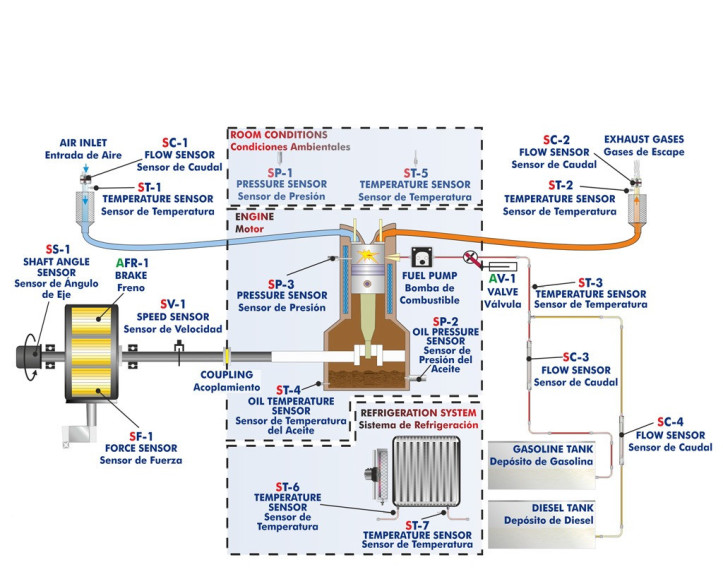

The element of the unit that offers load torque is an eddy current electromagnetic brake. It is supplied by a variator that allows to control the supply voltage and to vary its torque characteristics. The brake is jointly coupled to the shaft of the combustion engine by a double Cardan joint that transfers torque and power.

The unit also includes:

- Instrumentation: there are several sensors that provide us measurements of the variables under study.

- Start system: the engine includes its own electric starter motor that facilitates its operation.

- Fuel supply system: it carries the required fuel to the internal combustion engine.

- Cooling system: it carries out the cooling required for the correct operation of the engine. A forced water current removes the heat generated in the engine and transfers it to the atmosphere with a radiator.

- Air intake system: it allows the intake of fresh air in the engine. It contains the oxygen required to generate the combustion.

- System to remove the exhaust gases: it removes from the engine the substances generated during the combustion and reduces the noise inherent to the gases flow.

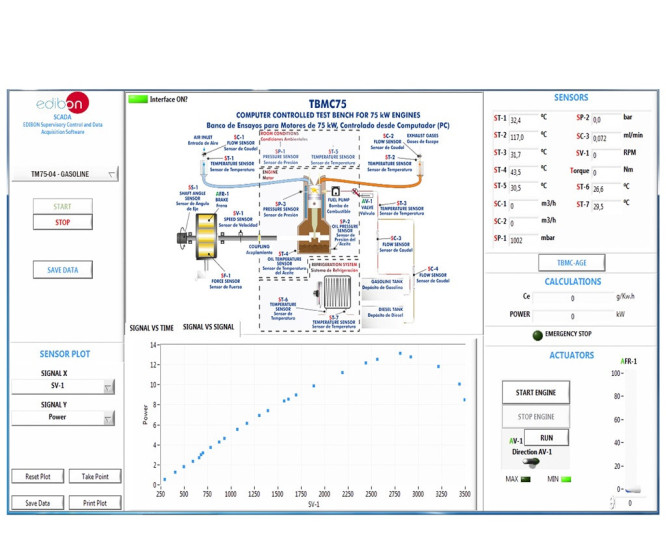

The Computer Controlled Test Bench for 75 kW Engines, "TBMC75", allows to study combustion engines, obtaining their characteristic curves by setting the accelerator of the engine to a specific position and varying the braking torque. Thus, different points of the torque or power versus velocity characteristic curve are obtained. Such curve will be at full load if the accelerator is at its maximum position.

The Computer Controlled Test Bench for 75 kW Engines, "TBMC75", is an advanced solution for testing internal combustion engines of up to 75 kW. This bench allows for the collection of precise data on performance, torque, power, and other fundamental parameters. For proper operation, it can be integrated with any of the engines listed below.

To operate the "TBMC75", it is necessary to select at least one of the following compatible engines:

- TM75-01/R. Water-cooled 4-Stroke 4-Cylinder Gasoline Engine for TBMC75 (Reconditioned). This gasoline engine offers efficient and stable operation thanks to its 4-cylinder configuration and water cooling system. The refurbished version is a cost-effective option, but it is also available as a new engine upon request. Applications: Medium and large cars: Perfect for passenger vehicles with high-performance engines. Light industrial machinery: Used in generators and construction unit. Research in energy efficiency.

- TM75-02. Water-cooled 4-Stroke 4-Cylinder Diesel Engine for TBMC75. The "TM75-02" diesel engine is recognized for its durability and fuel efficiency. Its water cooling system ensures consistent performance even in extreme conditions. Applications: Commercial and cargo vehicles: Used in light trucks and buses. Agricultural machinery: High-power tractors and harvesters. Industrial generators: Power supply in critical environments.

- TM75-02/R. Water-cooled 4-Stroke 4-Cylinder Diesel Engine for TBMC75 (Reconditioned). This refurbished engine offers the same efficiency and robustness as its new version, but at a more accessible cost. It is ideal for applications where performance must be accompanied by efficient cost management. Applications: Commercial fleets: Used in refurbished trucks and buses to save resources. Diesel generators: Excellent for temporary projects or tight budgets.

- TM75-03/R. Water-Cooled 4-Stroke 4-Cylinder Gasoline and LPG Engine for TBMC75 (Reconditioned). This dual engine provides flexibility by operating on gasoline or LPG, making it a versatile and eco-friendly option. The refurbished version allows for more economical access, with the option for a new engine upon request. Applications: Commercial vehicles: Forklifts and hybrid vehicles that use LPG to reduce emissions. Emergency power systems: Dual generators that operate on gasoline or LPG depending on fuel availability.

- TM75-04. Water-Cooled 4-Stroke 3-Cylinder Gasoline Engine for TBMC75. This engine is more compact but maintains high performance thanks to its 3-cylinder configuration. Its optimized design and water cooling system ensure adequate energy efficiency for various applications. Applications: Compact cars: Engines in efficient and lightweight vehicles. Hybrid systems: Vehicles that seek to balance performance and economy. Industrial unit: High-performance portable generators.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Determination of the characteristic curves of an internal combustion engine at different speed regimes:

- Torque.

- Power.

- Specific consumption of fuel.

- Determination of the efficiency, fuel specific consumption and air-fuel ratio of an internal combustion engine.

- Determination of the volumetric efficiency and the average effective pressure of an internal combustion engine.

より実用的な練習をして、ユニットを完成させる

- Familiarization with four strokes petrol and diesel engines.

- Comparison of the characteristics of diesel oil and petrol engines.

- Study of cooling in alternative internal combustion engines.

- Pressure measurement in the combustion chamber of an engine (it requires the accessory TM75-01SP or TM75-02SP).

- Graphical representation of the combustion chamber pressure versus time and versus the position of the crankshaft (it requires the accessory TM75-01SP or TM75-02SP).

- Familiarization with the concept of supercharging for engines supercharged by a set of turbo and intercooler (it requires the TM75-02).

- Analysis of an internal combustion engine exhaust gases (it requires the TBMC-AGE accessory). Recommended for petrol engines.

- Calculation of the heat contained in the exhaust gases of an internal combustion engine (it requires the TBMC-CG).

- Study of the ignition of a petrol combustion engine (it requires the additional recommended element STRO).

- Sensors calibration.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TBMC75 unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TBMC75 unit process.

- Several other exercises can be done and designed by the user.

利用可能な類似の機器

7.5 kW用コンピュータ制御テストベンチ

11 kW用コンピュータ制御テストベンチ

ディーゼルエンジン試験および診断総合ベンチ

故障シミュレーション付きガソリンエンジンの総合試験および診断ベンチ

ブレーキおよび診断ソフトウェアを備えたハイブリッドエンジン用総合試験・診断ベンチ

補完的な機器

2.2 kW用コンピュータ制御テストベンチ

7.5 kW用コンピュータ制御テストベンチ

11 kW用コンピュータ制御テストベンチ

故障シミュレーション付きガソリンエンジンの総合試験および診断ベンチ

ディーゼルエンジン試験および診断総合ベンチ

ブレーキおよび診断ソフトウェアを備えたハイブリッドエンジン用総合試験・診断ベンチ

コンピューター制御排気ガス熱量計

排気ガス分析装置

品質

アフターサービス

クッキーの設定

クッキーの設定