At EDIBON, we have completed a new installation at the Department of Civil Engineering at the Papua New Guinea University of Technology (PNGUOT). This...

Water is an essential resource for human life, economic development, and the planet’s ecological balance. However, as we move deeper into the 21st...

Water is an essential resource for human life, economic development, and the planet’s ecological balance. However, as we move deeper into the 21st century, its availability and quality are increasingly at risk. Population growth, industrial and agricultural pollution, water scarcity in vulnerable...

In a world where climate change represents one of the greatest threats to our future, carbon dioxide (CO2) adsorption has become an urgent priority. The increasing concentration of CO2 in the atmosphere, primarily driven by human activities such as fossil fuel combustion and deforestation, has...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

ダイレクトエアキャプチャー (DAC) は、液体溶媒や固体吸収剤との化学反応を利用して空気中のCO₂を直接除去する革新的な技術です。コストの高さやエネルギー消費といった課題はあるものの、DACは大気中のCO₂濃度を減らし、気候変動を緩和する潜在的な解決策を提供します。DACの研究開発を継続することが、その実現可能性と効果を向上させるために重要です。

下水処理施設

飲料水処理プラントが安全な飲料水の供給に焦点を当てる一方で、下水処理施設は使用済みの水を再び環境に放出する前に処理します。

これらの施設は、水資源と公衆衛生の保護に重要な役割を果たします。

高度な処理技術は、汚染物質を除去し、処理された水が環境基準を満たすことを保証します。

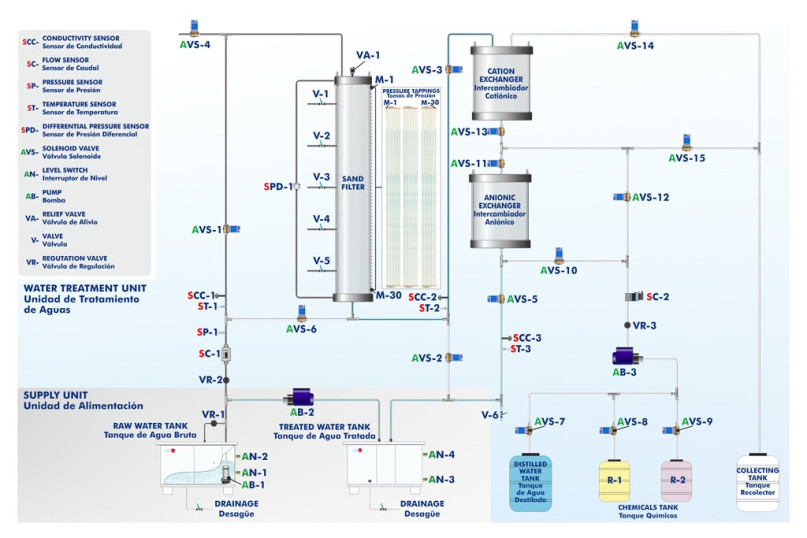

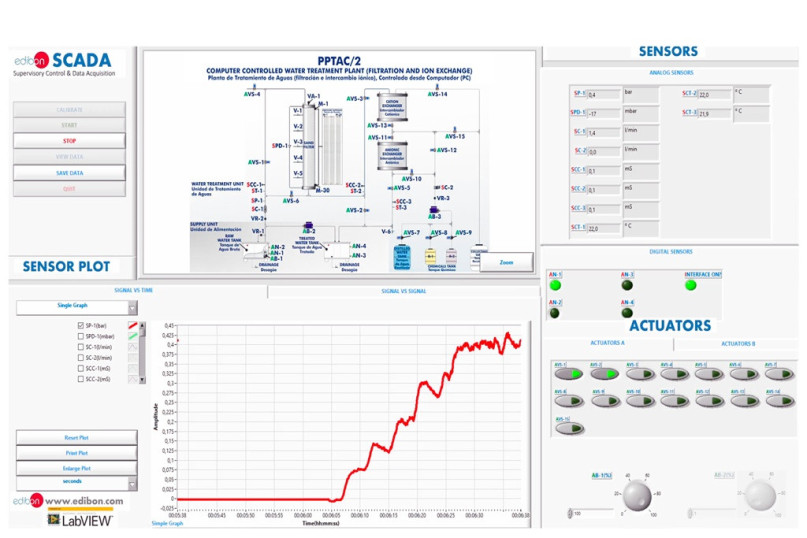

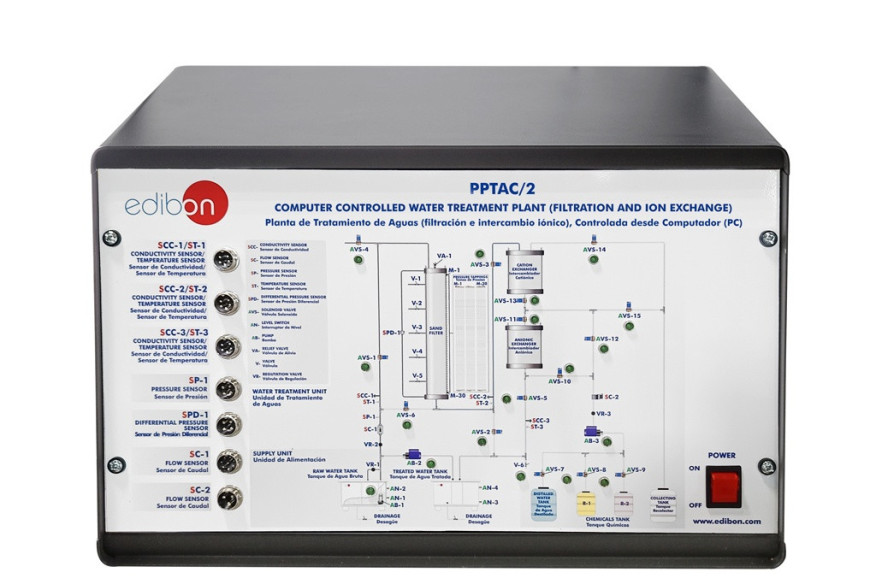

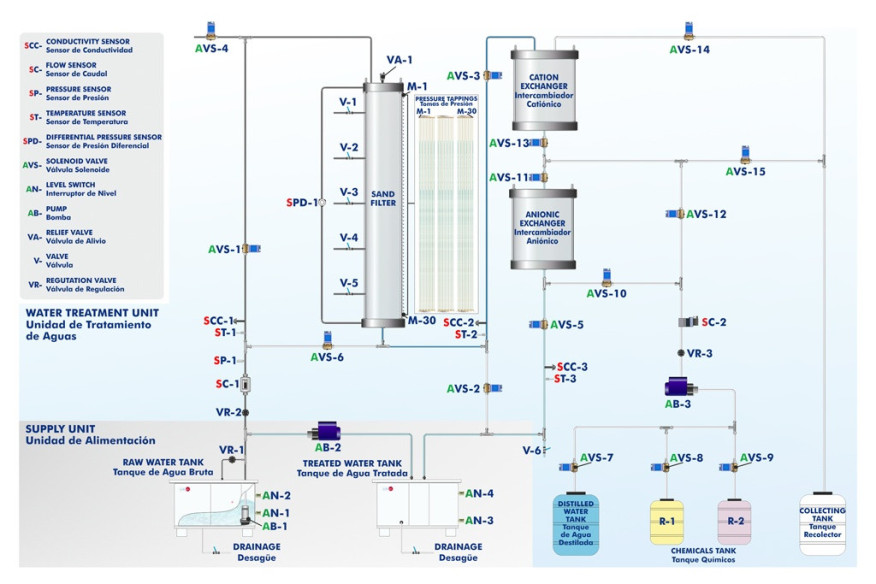

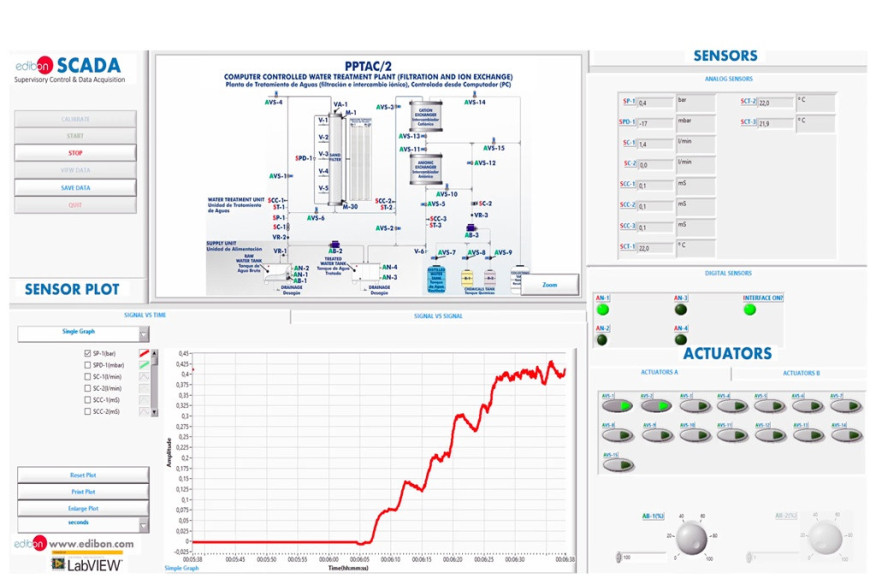

Food Technology is a branch of Food Science based on multidisciplinary knowledge of nutrition, chemical analysis, physics, biochemistry and engineering. Water treatment technologies obtain drinking water, so necessary for our life.

Both disciplines have become in recent years an indispensable...

クッキーの設定

クッキーの設定