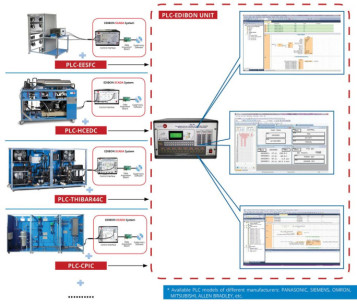

Generally, PLC controllers include functionalities such as analog and digital I/O, a memory table to share I/O and variable values, and a set of sequential instructions that define the machine behavior.

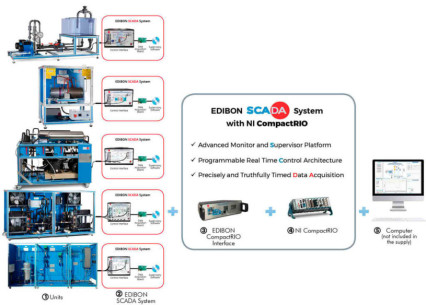

In addition to these PLC capabilities, National Instruments CompactRIO systems can provide more sophisticated functionalities:

- High-speed data acquisition and analysis.

- Motion control, vision and inspection.

- Signal processing based on custom hardware.

- Intelligent Data logging and embedded complex mathematics.

- Etc.

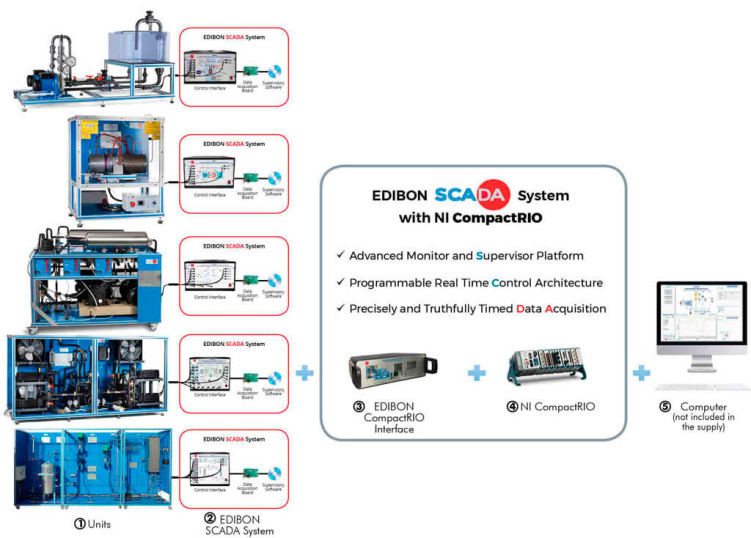

EDIBON Industrial Modular System with NI CompactRIO contains three components: a real time controller, a reconfigurable field-programmable gate array (FPGA) an industrial I/O modules.

The real-time controller contains an industrial processor that reliably and deterministically executes LabVIEW Real-Time applications and offers multiplate sampling control, execution tracing, integrated data logging, and communication with peripherals.

The reconfigurable FPGA inside the chassis is the center of the embedded system architecture. The reconfigurable I/O (RIO) modules of the FPGA are directly connected to the I/O modules for high-performance access to the I/O circuits of each module and unlimited timing and triggering and flexible synchronization.

I/O modules include insulation, conversion circuits, signal conditioning and built-in connectivity for direct connection to industrial sensors/ actuators.

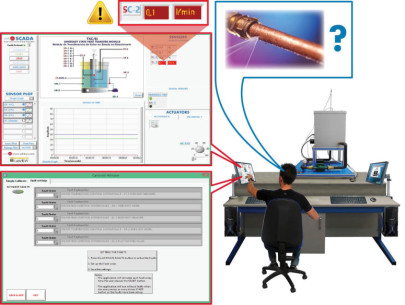

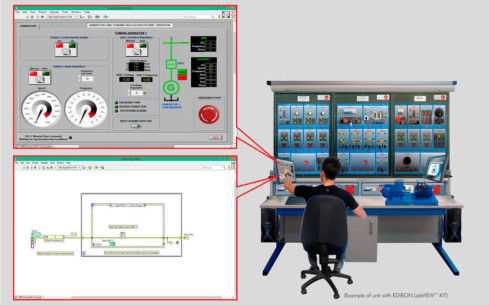

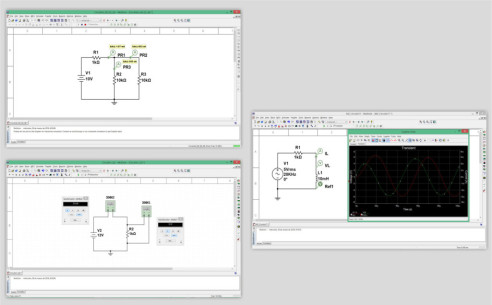

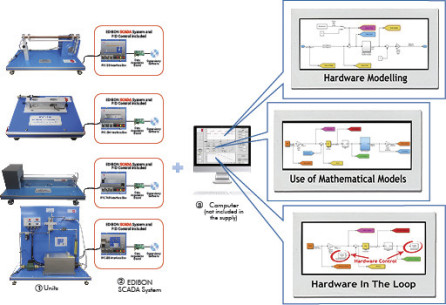

With EDIBON Software Development KIT, users can get started in the fields of instruments and hardware control and programming. Researchers can work without limits with any value and parameter, control the data acquisition and its subsequent processing and change the control algorithms.

The readings of sensors and calculated values can be viewed in real time and the hardware elements, such as valves, pumps, turbines, etc., can be controlled.

Also a ICAI and ELK licenses are included free of charge.

クッキーの設定

クッキーの設定