The Positioning Workstation, "AE-PLC-SPO", has been designed by EDIBON to studiy three-axis positioners for computer integrated manufacturing systems. It sorts incoming pieces based on material and dimensions using a PLC-controlled manipulator.

The "AE-PLC-SPO" is a positioning workstation commanded by a PLC that checks the material and dimensions of the incoming pieces to sorting in three different places.

The "AE-PLC-SPO" uses a three axis manipulator to pick and place the incoming pieces. The "AE-PLC-SPO" has a sorting area where the unit checks the dimensions and the material of the piece and also has three different storage places, where the system place the pieces, depending on the material or the dimensions of them.

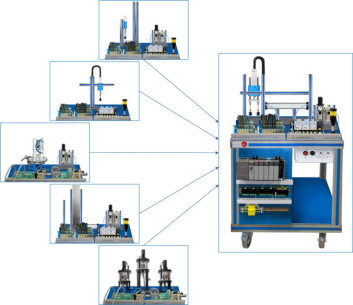

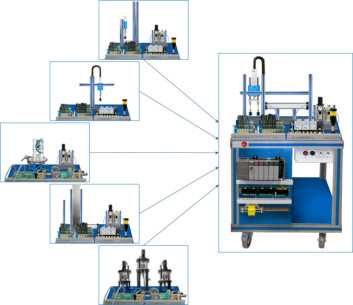

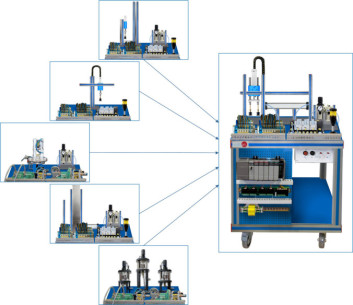

The "AE-PLC-SPO" workstation is designed as a modular system to facilitate the understanding.

The main components are:

- The PLC: composed of the CPU limit and all extra modules needed to perform a correct working of the workstation.

- The Control Panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The Pneumatic Circuit: contains the required solenoid valves, the pressure components, the filters and regulators to assure the appropriate working of the unit.

- The Workstation: composed of real industrial components used by the rotary table systems such as reed sensors, presence sensors, DC motor, inductive sensors, rotary table with 8 positions, etc.

The "AE-PLC-SPO" is an independent workstation that can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing System*.

*The Flexible manufacturing systems product list is available at the "6.-MECHATRONICS, AUTOMATION AND COMPUMECHATRONICS" area.

The pneumatic circuit and the workstation are distributed in the following sections:

- Air Treatment System: contains a filter-regulator block with a water trap and shut-off valve to control the air pressure input to the unit. Includes a dual-scale pressure gauge to visualize the pressure level supplied to the unit.

- Parts Feeding Section: contains vertical storage for storing the parts. The parts are supplied to the unit one by one through a double-acting cylinder. The two inputs of the double-acting cylinder each have an adjustable airflow valve with a bypass to regulate the cylinder speed.

- Parts Verification Section: designed to detect whether the parts supplied to the unit have a hole in the center and if they are made of metal. The parts verification module checks this feature for further classification of unwanted parts. This verification is carried out using a double-acting cylinder with a height sensor and an inductive sensor. The two inputs of the double-acting cylinder each have an adjustable airflow valve with a bypass to regulate the cylinder speed.

- Parts Displacement and Sorting Section: designed to displace and sort the verified parts into storage. This action is carried out by a manipulator that can move in all three coordinate axes and a telescopic suction cup. The manipulator moves in the X and Y axes using two linear electric actuators with a DC motor, the Z axis is a single-acting cylinder, and its input has an adjustable airflow valve with a bypass to regulate the cylinder speed.

- Signaling Tower: contains green, yellow, and red LED lights to indicate the system's status.

- Solenoid Valve Block: is a distributor block of pneumatic valves with 4 solenoid valves, three of which operate as 5/2 monostable solenoid valves and one as a 5/2 bistable solenoid valve.

- Electrical Terminal Block: contains all accessible and identified unit signals for manual unit checking. The electrical terminal block has color-coded terminals to help the user identify the type of each signal, and it also contains the name of each signal.

クッキーの設定

クッキーの設定