At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-MR3 学習ステーション 回転テーブル:自動加工制御(穴あけと研磨の研究)

革新的なシステム

関連ニュース

概要

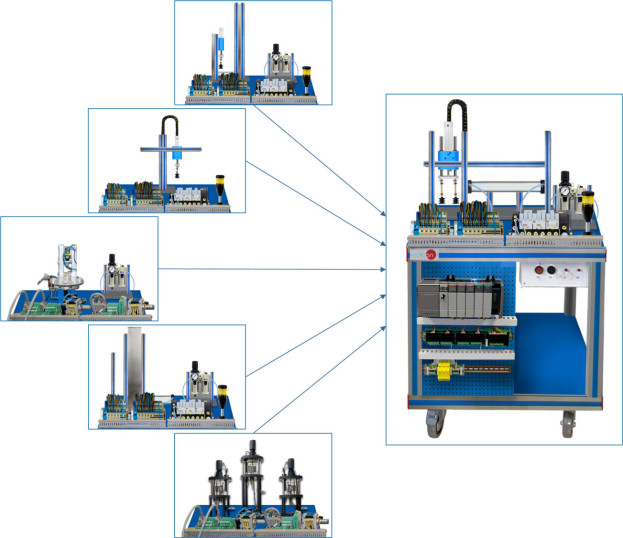

The "AE-PLC-MR3" is a processing workstation with a rotary table commanded by a PLC. This unit takes a piece from the input area, checks if the position of piece is correct, and simulates drilling the piece with a movable drilling machine. Finally the workstation places the piece to the exit piece area. The "AE-PLC-MR3" also includes a polish tool to change the process and simulates the polishing of the piece.

The "AE-PLC-MR3" workstation is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by the CPU PLC unit and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The workstation: is composed by real industrial components used by the industrial processing systems with rotary tables such as limit switch sensors, capacitive sensors, drilling machine, etc.

The "AE-PLC-MR3" is an independent workstation that can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Introduction to flexible manufacturing system (FMS).

- Introduction to electrical actuators.

- Study of the sensor detection.

- Manual control of the rotary table system.

- Manual control of the quality control and drilling process on a rotary table.

- Automatic control of the rotary table system.

- Automatic control of the quality control and drilling process on a rotary table.

- Change the parameters of the rotary table process.

- Optimize the process time.

- Study and analysis of the faults inserted in the process with the fault generation module.

利用可能な類似の機器

6.2.5.3.- 回転式ワークステーションアプリケーション

AE-PLC-MR1

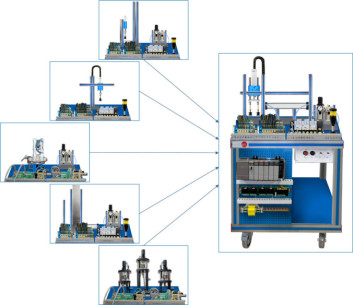

The Rotary Table Station: Feeding, Quality Control and Assembly (dimensional study), "AE-PLC-MR1", designed by EDIBON, is an automatic rotary table with a feeder, quality control and mounting system integrated into it. The "AE-PLC-MR1" has a...

6.2.5.3.- 回転式ワークステーションアプリケーション

AE-PLC-MR2

学習ステーション 回転テーブル:供給、品質管理、組立(材料と色の研究)

The "AE-PLC-MR2" an automatic rotary table with a feeder, quality control and mounting system integrated in it. The "AE-PLC-MR2" has a vertical storage, the system provide pieces one by one to the rotary table, then, a quality control system check...

6.2.5.3.- 回転式ワークステーションアプリケーション

AE-PLC-MR4

学習ステーション 回転テーブル:充填、瓶詰め、キャップ閉め

The "AE-PLC-MR4" is a rotary table workstation commanded by a PLC that perform the bottling, filling and capping functions.The "AE-PLC-MR4" workstation has been designed as a modular system to facilitate the understanding of the equipment...

補完的な機器

6.2.5.3.- 回転式ワークステーションアプリケーション

AE-PLC-MR1

学習ステーション 回転テーブル:供給、品質管理、組立(寸法の研究)

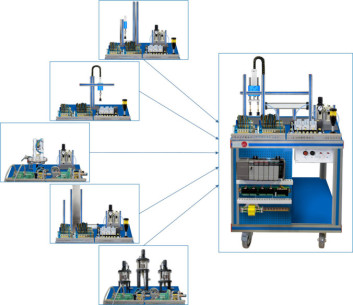

The Rotary Table Station: Feeding, Quality Control and Assembly (dimensional study), "AE-PLC-MR1", designed by EDIBON, is an automatic rotary table with a feeder, quality control and mounting system integrated into it. The "AE-PLC-MR1" has a...

6.2.5.3.- 回転式ワークステーションアプリケーション

AE-PLC-MR2

学習ステーション 回転テーブル:供給、品質管理、組立(材料と色の研究)

The "AE-PLC-MR2" an automatic rotary table with a feeder, quality control and mounting system integrated in it. The "AE-PLC-MR2" has a vertical storage, the system provide pieces one by one to the rotary table, then, a quality control system check...

6.2.5.3.- 回転式ワークステーションアプリケーション

AE-PLC-MR4

学習ステーション 回転テーブル:充填、瓶詰め、キャップ閉め

The "AE-PLC-MR4" is a rotary table workstation commanded by a PLC that perform the bottling, filling and capping functions.The "AE-PLC-MR4" workstation has been designed as a modular system to facilitate the understanding of the equipment...

品質

アフターサービス

クッキーの設定

クッキーの設定