At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-AL 保管学習ステーション

革新的なシステム

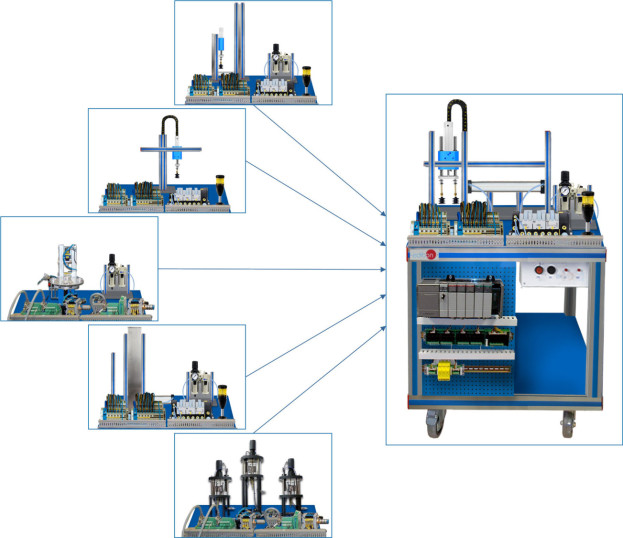

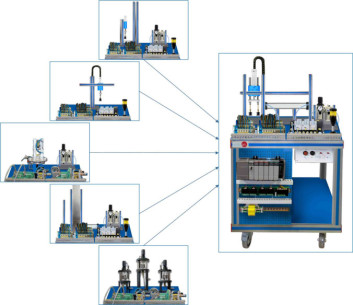

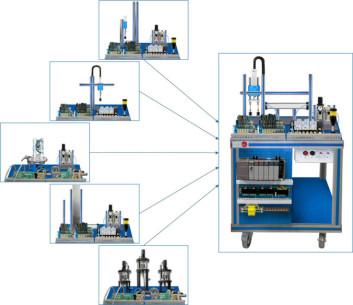

The "AE-PLC-AL" is an automatic Storage Workstation commanded by a PLC that moves the pieces at the desired position in a numbered grid.

関連ニュース

概要

The "AE-PLC-AL" is an automatic Storage Workstation commanded by a PLC that moves the pieces at the desired position in a numbered grid.

The "AE-PLC-AL" uses two electric linear actuators and a pneumatic manipulator to configure an automatic three axis storage system. The "AE-PLC-AL" uses the vacuum technology to move the pieces at the numbered grid of the storage.

This unit is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by the CPU limit and all extra modules needed to perform a corrent working of the workstation and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The pneumatic circuit: contains the required solenoid valves, the vacuum components, the filters and regulators to assure the appropriate working of the unit.

- The workstation: is composed by real industrial components used by the industrial feeder systems such as electric linear actuators, presence sensors, rotary actuators, vacuum cups, etc.

The "AE-PLC-AL" is an independent workstation that can work alone and/or in conjunction with other workstation to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

演習と指導の慣行

マニュアルに含まれるガイド付き実習

- Introduction to flexible manufacturing system (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Introduction to vacuum technology.

- Study of the sensor detection.

- Configuration of a pneumatic application.

- Manual control of a storing system.

- Automatic control of a storing system.

- Change the parameters of the storing process.

- Optimization of the process time.

- Study and analysis of the faults inserted in the process with the fault generation module.

利用可能な類似の機器

6.2.5.8.- ストレージワークステーションアプリケーション

AE-PLC-ALT

The "AE-PLC-ALT" is a Buffer Workstation commanded by a PLC that performs the functions of temporal storage of piece. The buffering function is used in many situations in the real industry for security or between different manufacturing stages.The...

6.2.5.8.- ストレージワークステーションアプリケーション

AE-PLC-ALB

ボトル保管学習ステーション

The "AE-PLC-ALB" is an automatic storage workstation for bottles with three degrees of freedom X-Y-Z. The "AE-PLC-ALB" is composed by two linear electrical actuators to move over the X-Y axes, and a pneumatic actuator (Z axis) with a vacuum cup...

6.2.5.8.- ストレージワークステーションアプリケーション

AE-PLC-ALV

垂直保管学習ステーション

The Vertical Storage Workstation, "AE-PLC-ALV", studies the control of a vertical positioning, storage and sorting system. It enables understanding of controlling an automatic vertical three-axis storage system..It includes PLC, pneumatic...

補完的な機器

6.2.5.8.- ストレージワークステーションアプリケーション

AE-PLC-ALT

一時保管学習ステーション

The "AE-PLC-ALT" is a Buffer Workstation commanded by a PLC that performs the functions of temporal storage of piece. The buffering function is used in many situations in the real industry for security or between different manufacturing stages.The...

6.2.5.8.- ストレージワークステーションアプリケーション

AE-PLC-ALB

ボトル保管学習ステーション

The "AE-PLC-ALB" is an automatic storage workstation for bottles with three degrees of freedom X-Y-Z. The "AE-PLC-ALB" is composed by two linear electrical actuators to move over the X-Y axes, and a pneumatic actuator (Z axis) with a vacuum cup...

6.2.5.8.- ストレージワークステーションアプリケーション

AE-PLC-ALV

垂直保管学習ステーション

The Vertical Storage Workstation, "AE-PLC-ALV", studies the control of a vertical positioning, storage and sorting system. It enables understanding of controlling an automatic vertical three-axis storage system..It includes PLC, pneumatic...

品質

アフターサービス

クッキーの設定

クッキーの設定