EBGC 바이오가스 공정 장비, 컴퓨터 제어

혁신적인 시스템

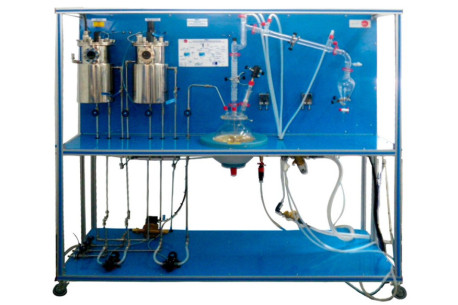

The Computer Controlled Biogas Process Unit, "EBGC", is designed to study and understand the different processes given during the biogas generation through anaerobic breakdown, as well as the study of the different parameters that affect the anaerobic digestion itself and the value of the obtained biogas.

확장

실험실

관련 뉴스

일반적인 설명

The Computer Controlled Biogas Process Unit, "EBGC", is supplied with two packed anaerobic digesters. In this way, the user can work either in only one stage or in two stages, separating the different phases of the digestion process (the processes of hydrolysis, acidogenesis and acetogenesis would take place in the first digester, and the methanogenesis in the second digester).

Both digesters have a heating blanket that allows to regulate (PID Control) both the appropriate temperature for each part of the process and the operation with different ranges depending on the used microorganisms. Thus, it can operate at the psychrophilic range (room temperature), mesophilic range (temperatures around 35ºC) or thermophilic range (temperatures around 55ºC).

The unit has four computer controlled peristaltic pumps which enable the propelling of both the supply to be introduced in the digester and the acid and the base (introduced in two vessels located at the rear side) in order to adjust and control thoroughly the pH in each stage of the process. In case of working in an anaerobic digestion in two stages, one of the pumps carries the product from one of the digesters to the other, passing through a buffer tank which collects the excess of flow from the first reactor. The control of these pumps allows to know the different flows with which the unit is working.

Two volumetric tanks are also included for the storage and volume measurement of the generated biogas. The generated biogas flows through a pipe from the upper side of the digesters to these tanks, where the biogas volume is measured by means of a water displacement.

Such tanks have two parts: the upper side is where the generated biogas is collected and the second part, smaller than the first one and located below it, is used to collect the displaced water.

Each digester has a temperature sensor and a pH sensor. Their function is to follow the whole process and study the influence of the different controlling parameters in the anaerobic digestion.

Finally, the volumetric tanks, by their upper side, enable the flowing of the collected biogas through a pipe and its passing through a methane sensor (CH4) which allows to know the methane concentration in such current and this way, the biogas quality depending on four the physical-chemical conditions under which the anaerobic digestion is developed can be determined, as well as its value as a renewable energy source.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

연습 및 가이드

매뉴얼에 포함 된 가이드 실기 연습

- Study of the stabilization process.

- Study of the effect of temperature in the anaerobic digestion, purification and quality of the obtained biogas.

- Study of the pH effect of the feeding waste water in the anaerobic digestion, purification and quality of the obtained biogas.

- Study of the influence of the feeding rate in the anaerobic digestion, purification and quality of the obtained biogas.

- Study of the influence of the type of the feeding waste water in the anaerobic digestion, purification and quality of the obtained biogas.

- Study of the concentration of nutrients influence of the feeding waste water in the anaerobic digestion, purification and quality of the obtained biogas.

- Study of the hydraulic load effect in the anaerobic digestion, purification and quality of the obtained biogas.

- Study of the inhibitors influence in the anaerobic digestion, purification and quality of the obtained biogas.

- Comparison between the mesophilic and thermophilic anaerobic digestion and their influence in the biogas obtention.

- Determination of the optimum operation temperature.

- Determination of the optimum feeding rate.

- Determination of the optimum solids/water relation.

- Determination of the optimum degradable/non degradable solids relation.

- Determination of the multistage nature in the anaerobic digestion.

- Determination of the kinetics.

- Carbon balance.

- Solids balance.

- Biogas balance.

- Sensors calibration.

장비로 수행 할 수있는 더 많은 실용적 연습

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EBGC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EBGC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

비슷한 제품

Computer Controlled and Touch Screen Biogas Processing Plant

보완 장비

Computer Controlled Bioethanol Process Unit

Bioethanol Process Unit

Computer Controlled and Touch Screen Biogas Processing Plant

Biogas Process Unit

Computer Controlled Biodiesel Process Unit

Biodiesel Process Unit

Computer Controlled Biomass Process Unit

Biomass Process Unit

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정