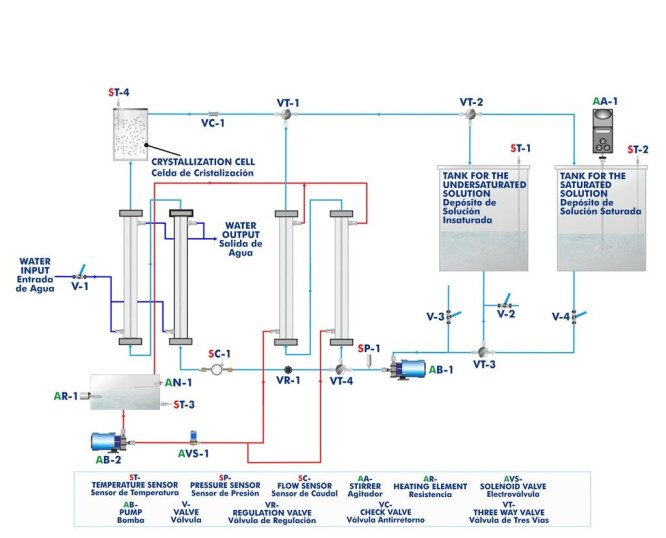

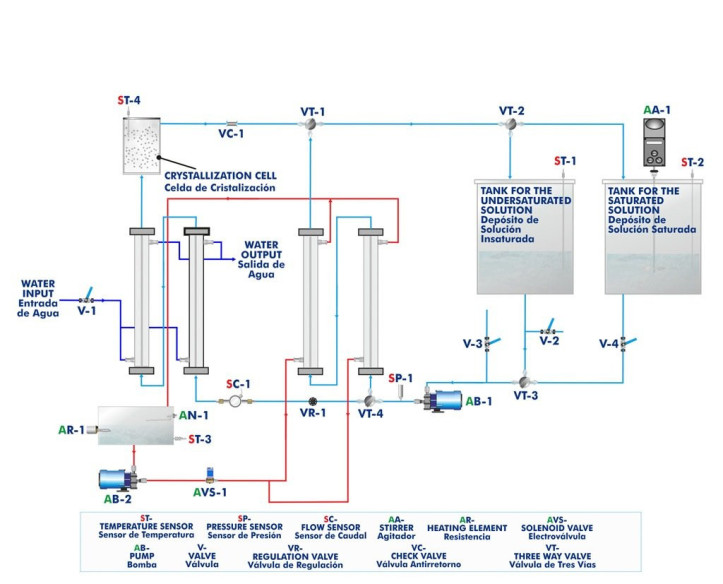

The Advanced Computer Controlled Crystallization Unit, "QUCC/A", designed by EDIBON, is a crystallization unit that by means of the cooling method allows the visualization and study of the industrial operation of mass transfer in which the formation of a solid from a homogeneous phase (solute in solution) takes place. It is suitable for crystallization tests of those components whose solubility varies with temperature.

The process is divided into two stages, a first one consisting of saturating the solution of the compound to be purified and a second cooling stage to obtain the crystals.

The process is divided into two circuits with two tanks, one for the oversaturated solution, whose tank incorporates a temperature sensor and a computer-controlled stirrer, and another circuit for the saturated solution, whose tank has a temperature sensor.

For the preparation of a saturated solution, there is an agitation tank and a pump that drives the solution to a heat exchanger, where it is heated to a temperature higher than the saturation temperature. Hot water circulates through the heat exchanger, which comes from a tank with a computer-controlled electrical resistance and is driven by a pump.

Subsequently, a small part of this insufficiently saturated solution is passed through the crystallization cell in the form of a bypass. This part of the solution is cooled with mains water (or from the recommended additional element (not included): Advanced Recirculating Cooling or Heating Water Recirculation Equipment, "TERA/A") in two heat exchangers, in order to promote crystallization. The drop in temperature causes the solution to go into an oversaturated state and crystals precipitate from the solution.

The crystallization cell consists of a unit equipped with porous filter discs at the inlet and outlet. The cell is opened to introduce crystals (crystallization germs). The flow conditions cause a fluidized bed to form in the cell and the potassium sulfate crystallizes on the germs, separating from the supersaturated solution. The retained crystals grow, so by weighing the crystals before and after the test and recording the elapsed time the rate of crystal growth can be determined.

The temperatures of both tanks and the temperature of the crystallization cell are recorded with sensors and monitored for proper operation.

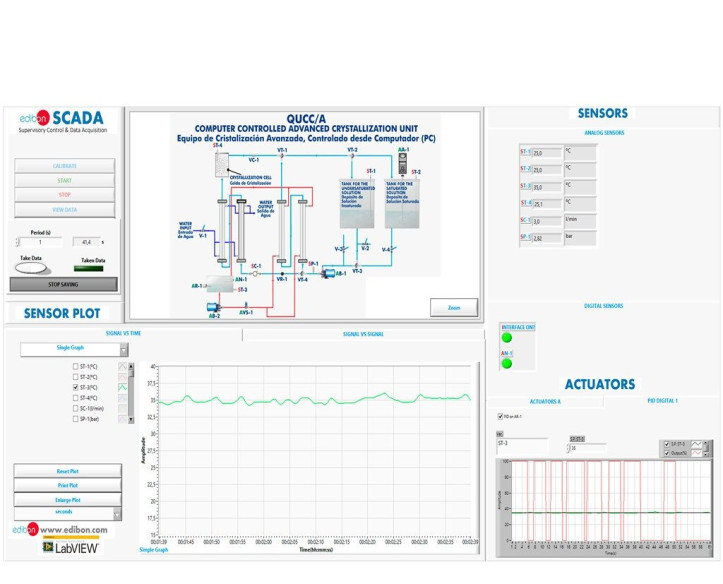

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

쿠키 기본 설정

쿠키 기본 설정