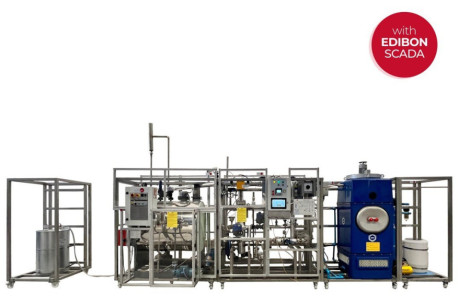

Pilot plants are small-scale processing plants designed to simulate industrial or research processes before large-scale implementation. They are essential for testing technologies, optimizing processes, and validating models before investing in mass production. These plants allow researchers and...

At EDIBON, we reaffirm our commitment to the advancement of clean and renewable energy, with a special focus on green hydrogen as a key driver for a more sustainable future. We are proud to have been selected to equip the first Green Hydrogen Laboratory in the Region of Murcia, a pioneering space...

The shift towards electric vehicles (EVs) has gained considerable momentum worldwide, promising a reduction in greenhouse gas emissions and a path to a more sustainable future. However, as the demand for EVs accelerates, so too does the need for large quantities of essential minerals, such as...

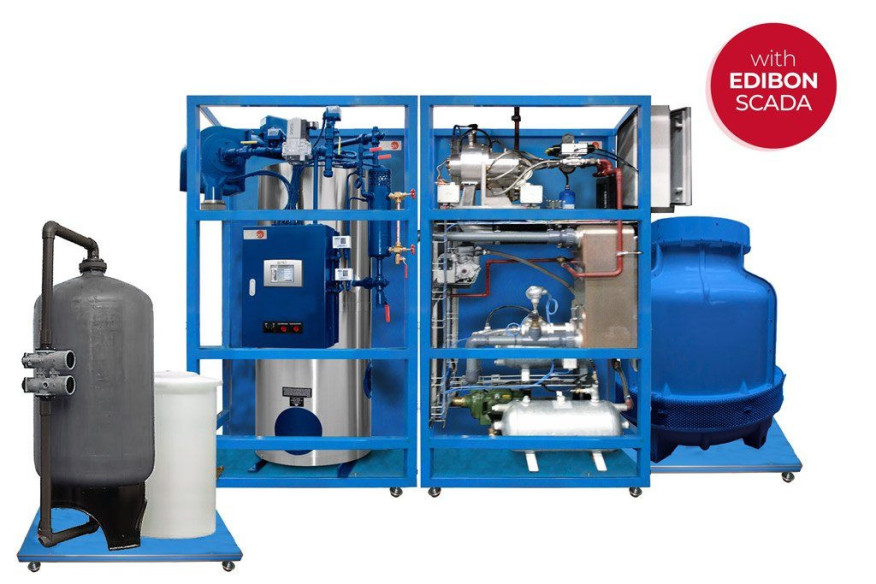

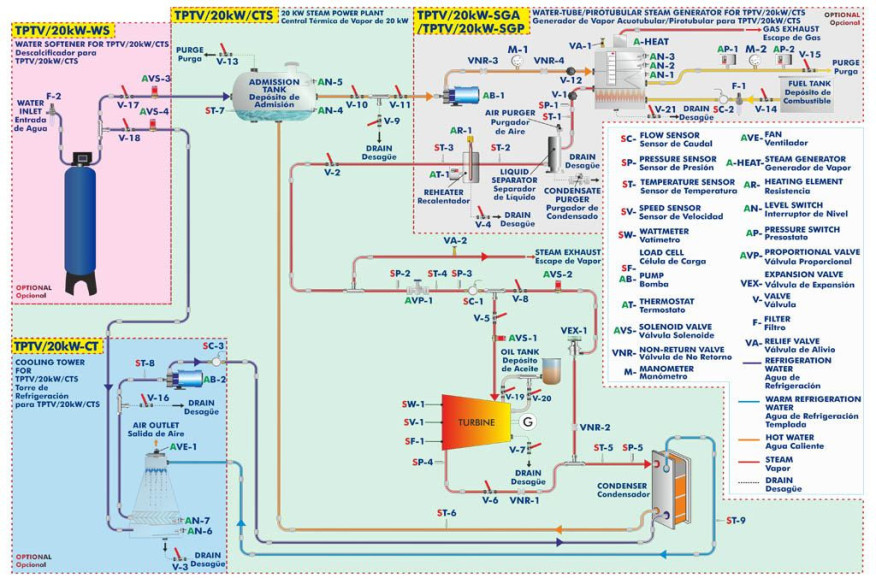

Thermodynamics and thermotechnology are fundamental fields of engineering that play a critical role across various industries, from energy generation to climate control. Understanding these foundational concepts is essential not only for engineers but also for fostering technological innovations...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

In a world where energy demand continues to rise and non-renewable resources are rapidly depleting, the need for sustainable, environmentally friendly solutions has never been more urgent. The circular economy and the use of organic biomass to produce biofuels are emerging as key answers to...

We are excited to celebrate the publication of the article by Prof. Dr. Nina Penkova titled "Performance of Diffusion Absorption Refrigerators with Variable Input Power" The study explores how absorption refrigerators, which utilize waste or solar energy for heating and cooling, can operate...

직접 공기 포집 (DAC)은 액체 용매 또는 고체 흡수제와의 화학 반응을 사용하여 공기 중의 CO₂를 직접 제거하는 혁신적인 기술입니다. 높은 비용과 에너지 소비와 같은 도전 과제가 있지만, DAC는 대기 중 CO₂ 농도를 줄이고 기후 변화를 완화하는 잠재적 해결책을 제공합니다. DAC의 연구 및 개발을 지속하는 것은 그 실행 가능성과 효과를 개선하는 데 중요합니다.

쿠키 기본 설정

쿠키 기본 설정