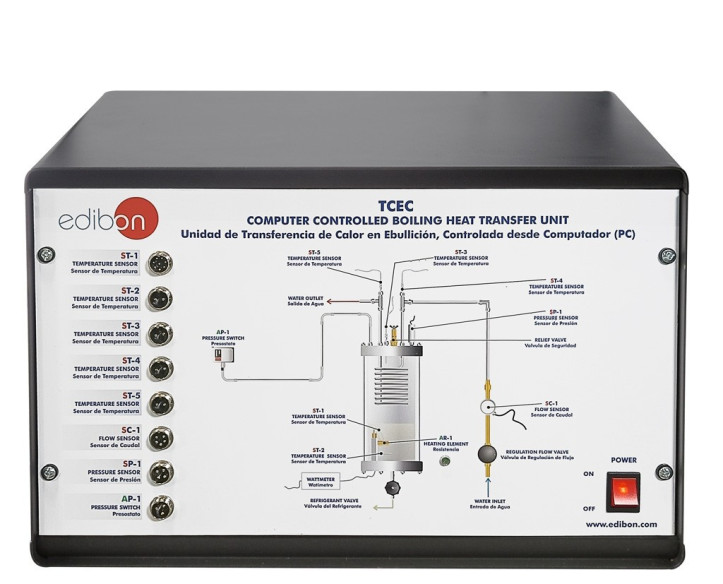

TCEC Computer Controlled Boiling Heat Transfer Unit

혁신적인 시스템

The Computer Controlled Boiling Heat Transfer Unit, "TCEC", consists of a heating element horizontally mounted inside a vertical glass chamber submerged in coolant. This heating element is connected to a cylindrical copper sleeve in contact with the coolant.

확장

실험실

관련 뉴스

일반적인 설명

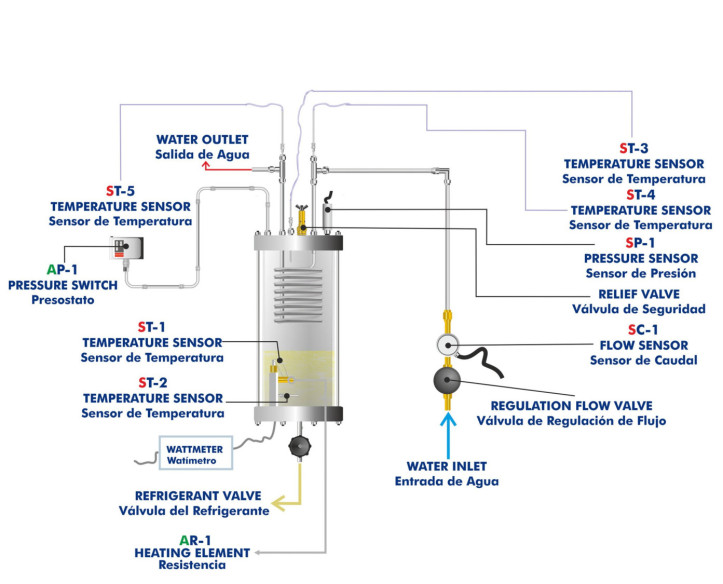

The Computer Controlled Boiling Heat Transfer Unit, "TCEC", consists of a heating element horizontally mounted inside a vertical glass chamber submerged in coolant. This heating element is connected to a cylindrical copper sleeve in contact with the coolant. Attached to this conductive cylinder there is a contact temperature sensor, which will measure the temperature of the hot surface. On the other hand, there is a second temperature sensor, which measures the temperature of the coolant.

The electric power consumed by the heating element is controlled from the computer and measured by a wattmeter.

The condenser is located at the upper end of the chamber. It is a nickel plated copper coil shaped tube through which cooling water flows. The coil condenses the vapor generated by the heating element and the liquid formed returns to the bottom of the chamber for re-evaporation.

The heat transferred can be obtained thanks to two temperature sensors, located at the water inlet and outlet of the coil, which together with a flow sensor allows to obtain the heat given to the water by the coolant.

The unit includes a pressure sensor that indicates the pressure in the condenser, a relief valve for the elimination or input of air in the chamber and a low pressure switch as safety control of the pressure.

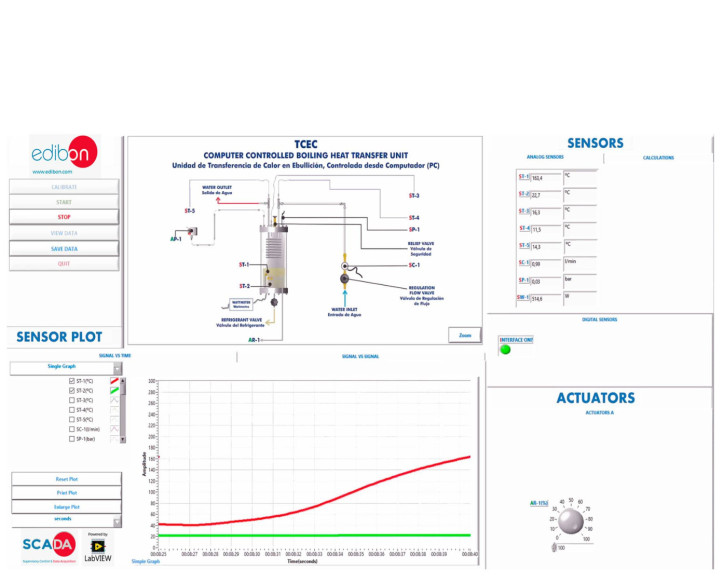

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

연습 및 가이드

매뉴얼에 포함 된 가이드 실기 연습

- Visual demonstration of the three boiling modalities (convective, nucleate and film boiling).

- Determination of the thermal flow and the superficial heat transfer coefficient.

- Effect of the pressure on the critical thermal flow.

- Film condensation.

- Demonstration of the liquid dragging for the vapour.

- Relationship between the pressure and the temperature.

- Air effect in an installation.

장비로 수행 할 수있는 더 많은 실용적 연습

- Sensors calibration.

- Study of the hysteresis of the flow sensor.

- Gauge pressure/Enthalpy.

- Properties of the SES-36.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TCEC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TCEC unit process.

- Several other exercises can be done and designed by the user.

비슷한 제품

보완 장비

Boiling Heat Transfer Unit

Computer Controlled Flow Boiling Demonstration Unit

Flow Boiling Demonstration Unit

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정