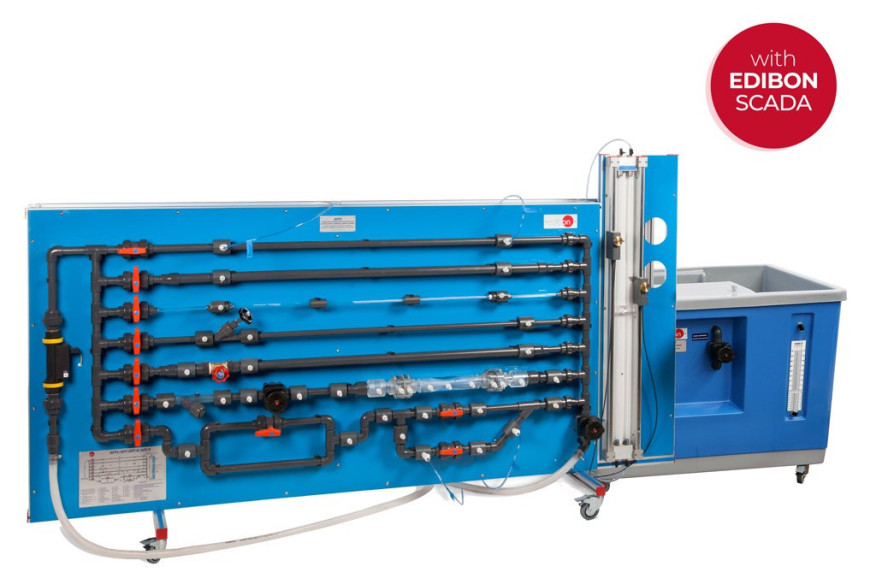

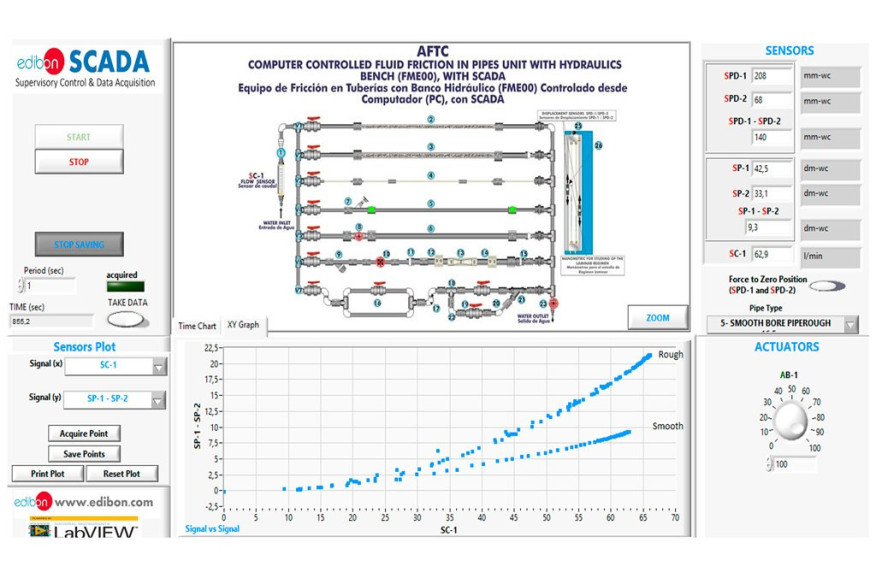

AFTC Computer Controlled Fluid Friction in Pipes, with Hydraulics Bench (FME00)

혁신적인 시스템

The Computer Controlled Fluid Friction in Pipes, with Hydraulics Bench (FME00), "AFTC", is designed to determine the friction coefficient in pipes of several diameters and roughness, to study the pressure losses and pressure development in different types of valves and fittings and to compare different methods to measure the flow.

확장

실험실

관련 뉴스

일반적인 설명

The Computer Controlled Fluid Friction in Pipes, with Hydraulics Bench (FME00), "AFTC", is designed to determine the friction coefficient in pipes of several diameters and roughness, to study the pressure losses and pressure development in different types of valves and fittings and to compare different methods to measure the flow.

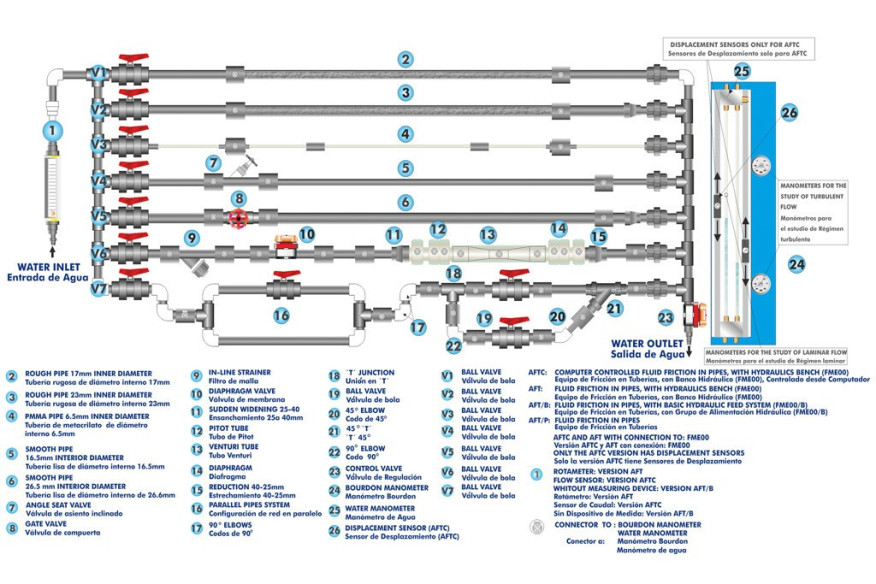

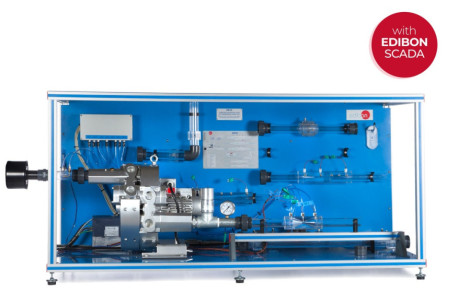

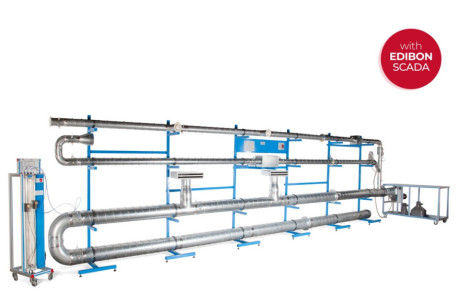

The unit contains six horizontal straight pipe sections made of different materials and with different diameters and roughness to study their influence in the pressure losses.

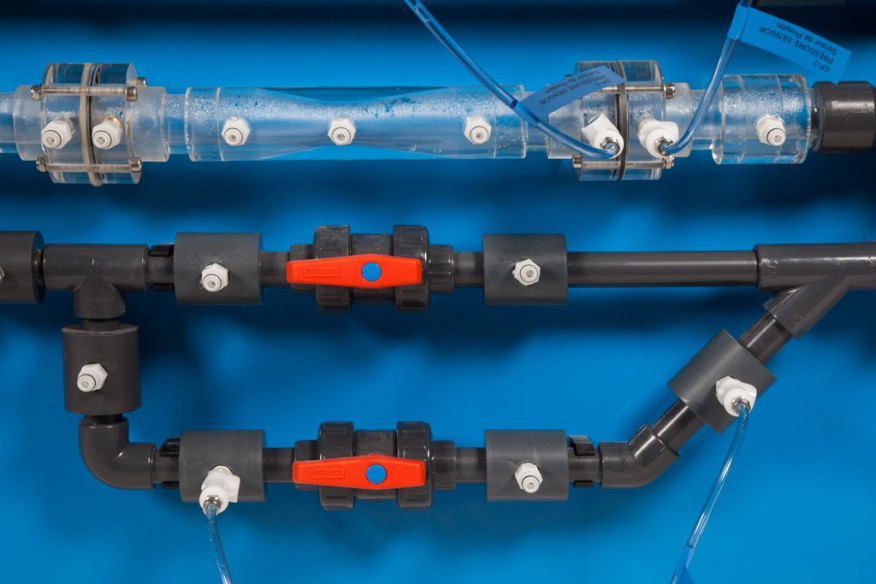

Additionally, a wide range of accessories are included for the study of losses in straight pipes, several types of valves (gate, ball, angle seat, etc.), pipe fittings (mesh filter, elbows, sudden widening, contraction, etc.) and measuring elements (Venturi tube, Pitot tube, orifice plate flowmeter, flow measuring nozzles, etc.).

Some of the measuring elements, like the Venturi tube, Pitot tube, etc., are transparent to observe their function.

The different pipe sections, valves and pipe fittings include several pressure measurement points with quick action connections to fit the tubing that is connected to the corresponding pressure measuring device.

The sections can be exchanged without tools.

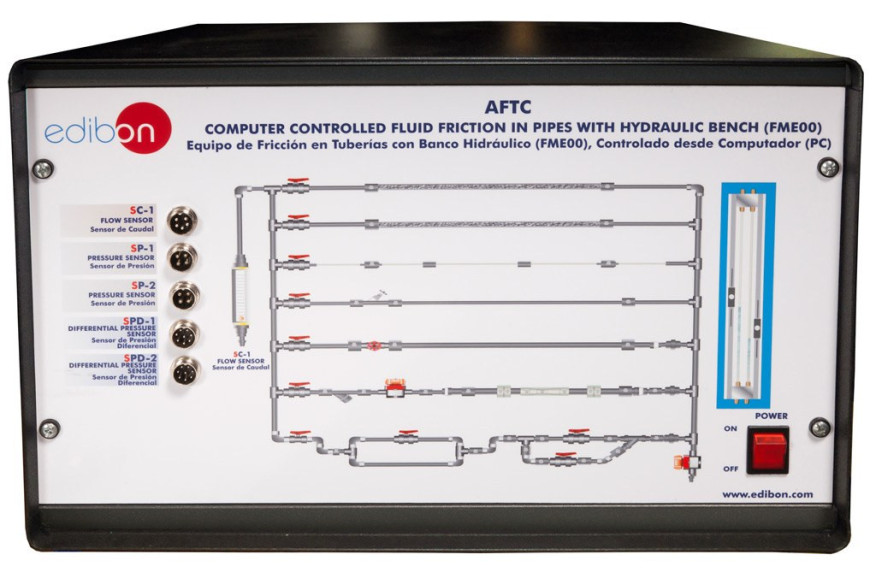

With this unit pressure losses can be investigated over a wide range of Reynolds numbers, thereby covering the laminar, transitional and turbulent flow regime. Two water manometric tubes and two displacement sensors allow to study the pressure losses in the laminar regime.

Two pressure sensors allow to obtain the pressure losses in the turbulent regimen. Additionally, it includes a flow sensor to measure and to compare measurements of flow with the Venturi tube and the Pitot tube.

Annular chamber shaped measuring points are located around the measuring elements for an accurate pressure measurement.

The unit includes the Hydraulics Bench (FME00), which incorporates a sump tank and a centrifugal pump to make water flow in a close circuit and to supply the "AFTC" unit, allowing an independent operation of the unit.

A flow sensor measures the flow impelled by the pump.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

연습 및 가이드

매뉴얼에 포함 된 가이드 실기 연습

- Determination of pressure loss due to friction in a rough pipe with an internal diameter of 17 mm.

- Determination of pressure loss due to friction in a rough pipe with an internal diameter of 23 mm.

- Determination of pressure loss due to friction in a smooth pipe with an internal diameter of 6.5 mm.

- Determination of pressure loss due to friction in a smooth pipe with an internal diameter of 16.5 mm.

- Determination of pressure loss due to friction in a smooth pipe with an internal diameter of 26.5 mm.

- Study of the influence of the diameter in the pressure loss due to friction in rough pipes.

- Study of the influence of the diameter in the pressure loss due to friction in smooth pipes.

- Study of the influence of the roughness in the pressure loss.

- Determination of the friction coefficient in a rough pipe with an internal diameter of 17 mm.

- Determination of the friction coefficient in a rough pipe with an internal diameter of 23 mm.

- Determination of the friction coefficient in a smooth pipe with an internal diameter of 6.5 mm.

- Determination of the friction coefficient in a smooth pipe with an internal diameter of 16.5 mm.

- Determination of the friction coefficient in a smooth pipe with an internal diameter of 26.5 mm.

- Study of the influence of the diameter in the friction coefficient in rough pipes.

- Study of the influence of the diameter in the friction coefficient in smooth pipes.

- Comparison of the friction coefficient in smooth and rough pipes.

- Determination of pressure loss in an angle-seat valve.

- Determination of pressure loss in a gate valve.

- Determination of pressure loss in a diaphragm valve.

- Determination of pressure loss in a ball valve.

- Comparison of pressure loss in different types of valves.

- Determination of pressure loss in an in-line strainer.

- Determination of pressure loss in a 90° elbow.

- Determination of pressure loss in a double 90° elbow.

- Determination of pressure loss in a 45° elbow.

- Determination of pressure loss in a 45° "T".

- Determination of pressure loss in a symmetrical "Y" branch.

- Determination of pressure loss in a narrowing.

- Determination of pressure loss in a gradual widening.

- Determination of pressure loss in a diaphragm.

- Comparison of pressure loss in the different fittings.

- Measurement of the flow with the Venturi tube.

- Determination of the discharge coefficient, Cd, in the Venturi d tube.

- Measurement of the flow with the Pitot tube.

- Determination of the discharge coefficient, Cd, in the Pitot tube.

- Comparison between the flow measured in the Venturi and Pitot tubes.

- Sensors calibration.

장비로 수행 할 수있는 더 많은 실용적 연습

- Study of the relationship between pressure losses due to fluid friction and the water flow rate.

- Determining the relationship between the pipe friction coefficients and Reynolds number for flow through a pipe with roughened bore.

- Determining of the resistance coefficients for bends, enlargements and contractions.

- Determining of characteristic curves of valves and fittings.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the AFTC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the AFTC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

비슷한 제품

Fluid Friction in Pipes Unit, with Basic Hydraulics Feed System (FME00/B)

Fluid Friction in Pipes Unit

보완 장비

Fluid Friction in Pipes Unit, with Hydraulics Bench (FME00)

Fluid Friction in Pipes Unit, with Basic Hydraulics Feed System (FME00/B)

Fluid Friction in Pipes Unit

Computer Controlled Pipe Network Unit, with Hydraulics Bench (FME00)

Pipe Network Unit, with Hydraulics Bench (FME00)

Pipe Network Unit, with Hydraulics Bench (FME00/B)

Mesh in Pipe Unit

Unit to Study the Pressure Drop of Compressible Fluids in Pipes

Computer Controlled Water Hammer Unit

Computer Controlled Flow of Compressible Fluids Unit

Computer Controlled Unit for Transient Drainage Processes in Storage Reservoirs

Computer Controlled Air Duct Systems Unit

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정