At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

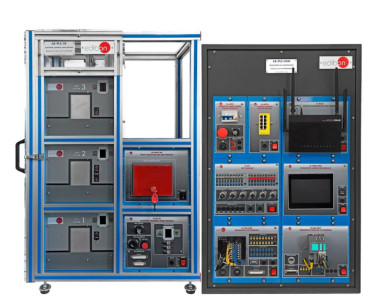

AE-PLC-CPI 산업 공정 제어 교육용 스테이션

혁신적인 시스템

The Industrial Processes Control Workstation, "AE-PLC-CPI", has been designed by EDIBON to study the control of flow, level, pressure, and temperature in an industrial process that includes several integrated circuits with different tanks and connections, all of which meet the requirements of a flexible cell.

관련 뉴스

일반적인 설명

The Industrial Processes Control Workstation, "AE-PLC-CPI", designed by EDIBON, is a unit that integrates different technologies to implement four closed-loop control loops: flow, level, temperature, and pressure. The different control loops are quickly and easily configured using a flexible system of ball valves and pipe connections.

The workstation features different types of digital and analog sensors and actuators to implement four closed-loop control loops: flow, level, pressure, and temperature.

PID control is performed through a proportional valve, which responds to variations indicated by the analog sensors corresponding to each control loop. Additionally, there are elements to generate disturbances in the system and observe the resulting response to the control.

It consists of three integrated circuits or stations:

- Cold water circuit.

- Hot water circuit.

- Water accumulator circuit.

The main components are:

- Workstation: composed of real industrial components, implemented to implement different PID controls, using analog and digital sensors, manual valves, solenoid valves, proportional valves, heat exchangers, radiators, and fans, etc.

- Pneumatic system: composed of a pneumatic ball actuator and an air filtration system.

- Control panel: with a Start/Stop button, emergency stop button, and indicator light to display the system status.

- Cold water circuit: composed of a proportional valve, flow meter, pressure sensor, pressure switch, plate heat exchanger, radiator, and fan. The pump circulates the water throughout the entire circuit. It has thermocouples to monitor the temperature.

- Hot water circuit: composed of thermocouples, a pump, and a plate heat exchanger. It is an independent circuit that transmits energy through the heat exchanger to the cold water circuit.

- Accumulator circuit: This circuit is derived from the cold water circuit and has a pneumatic ball actuator for draining. A solenoid valve directs the water pumped by the cold water circuit into the accumulator.

연습 및 가이드

매뉴얼에 포함 된 가이드 실기 연습

- Commissioning of a complex process control system.

- Operating principle of sensors: inductive, capacitive, ultrasonic, and infrared.

- Operating principle of actuators: pump and positioning valve

With PLC Programmable Controller (Base Unit):

- Structure of a PLC program.

- Programming and use of digital and analog signals.

- Programming different operating modes.

- Programming alternative branches (Grafcet).

- Communication with the remote extended I/O module.

- Optimization of timing and response times. Programming a PID level controller using a PLC.

- Optimization of timing and response times. Programming a PID flow controller using a PLC.

- Optimization of timing and response times. Programming a PID temperature controller using a PLC.

- Optimization of timing and response.

보완 장비

6.2.4.- PLC를 사용한 산업 애플리케이션

AE-PLC-SE

엘리베이터 제어 응용 프로그램

The Elevator Control Application, "AE-PLC-SE", has been designed by EDIBON with a double objective. On the one hand, this application allows to study the main electro-mechanical components that nowadays integrate any elevator. The most relevant...

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정