At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

MDU 기계 진단

혁신적인 시스템

The family of Machine Diagnosis Unit, "MDU", of Edibon, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.

관련 뉴스

일반적인 설명

The family of Machine Diagnosis Unit, "MDU", of Edibon, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.

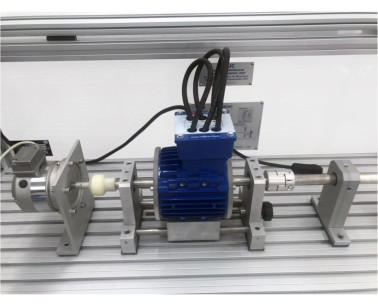

The MDU Base Unit, "MDU-UB", components are mechanical elements such as: flexible couplings for compensating misalignments, bearings with easily removable roller bearings, two rotor shafts of different lengths, two flywheels with replaceable counterweights and an asynchronous drive motor connected to a frequency converter and a tachometer generator.

All the elements can be mounted on an aluminum frame of 1100 x 770 mm with longitudinal grooves for displacement. They can be easily adjusted using screws.

The unit electronic console makes it possible to show on digital displays the speed and power of the motor, to adjust the motor speed using a potentiometer, and to select the direction of rotation of the motor.

The drive motor is mounted on a sliding carriage that includes two micrometer for precise alignment.

Specific cases of machine faults may be studied with the additional recommended elements, such as: shaft bending vibrations, shaft fissures, roller bearing faults, coupling vibrations, belt drive vibrations, gear faults, pump cavitation, blower vibration, and electromechanical vibrations. Furthermore, with the Bread and Load Unit, "MDU- BLU", ranges of two loading moments may be generated as well as two speed ranges.

The Software, Sensors and Control for MDU Unit, "MDU-SSC" is required to perform all measurements and analyze vibrations.

The MDU Base Unit, "MDU-UB", requires the following to be assembled:

- Mobile Structure for MDU, "MDU-MLB", or

- Top Table Structure for MDU, "MDU-SM".

We also offer the Computer Controlled Machine Diagnosis Unit, "MDUC", which includes the following components:

- MDU Base Unit, "MDU-UB".

- Software, Sensors and Control for MDU Unit, "MDU-SSC".

- Displacement Sensors for MDU Unit, "MDU-SD".

액세서리

7.4.3.- 설치 및 유지 관리 관행

MDU-MLB

The Mobile Structure for MDU, "MDU-MLB", is a robust structure designed to quickly and easily assemble the various elements of the MDU Base Unit, "MDU-UB" or the Computer Controlled Machine Diagnosis Unit, "MDUC", and thus assemble a mobile test...

7.4.3.- 설치 및 유지 관리 관행

MDU-SM

MDU 장치용 데스크톱 구조

A bench-top structure consisting of a slotted table with anodized aluminum frames of 1100 x 770 x 820 mm.It has a transparent protective cover that protects against the rotating parts and allows us to observe the different experiments. The cover...

7.4.3.- 설치 및 유지 관리 관행

MDU-SSC

소프트웨어, 센서 및 제어장치를 갖춘 MDU 장치

The aim of the vibration analyzer is to assess the machine diagnosis testing with the different kits related to the vibration interface technology.The system consists of two acceleration sensors, a speed sensor, a measuring amplifier with...

7.4.3.- 설치 및 유지 관리 관행

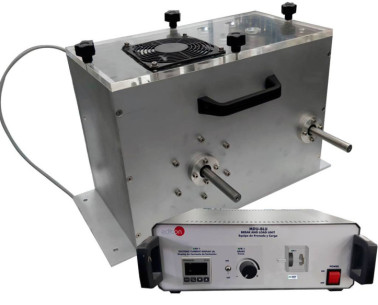

MDU-BLU

제동 및 하중 장비

The Break and Load Unit, "MDU-BLU", of EDIBON is a magnetic particle brake, a display unit and an electrical control. It is possible to precisely adjust the braking moment. The excitation current is used as a measurement of the braking moment and...

7.4.3.- 설치 및 유지 관리 관행

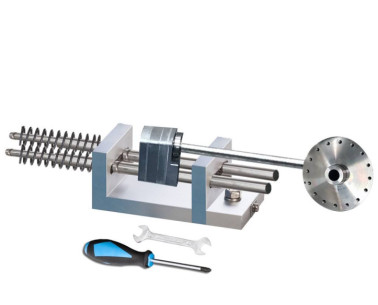

MDU-SES

탄성 나무 세트

The Set of Elastic Shaft, "MDU-SES", of EDIBON allows to study the behavior of an elastic rotor subjected to imbalance and balance of elastic rotors in operation. It is possible to study the resonance and the phenomena occurred in subcritical and...

7.4.3.- 설치 및 유지 관리 관행

MDU-SRS

균열이 있는 축 세트

It is important that fissures resulting from material fatigue in rotating machines are detected in good time before the breakage occurs, which usually leads to fatal consequences.The Set of Rotating Shaft with Crank, "MDU-SRS", consists of two...

7.4.3.- 설치 및 유지 관리 관행

MDU-SRBF

베어링 결함 세트

To determine the remaining life cycle of a roller bearing and decide on its replacement, the slow variation of the vibration spectrum is analyzed. The spectral distribution will enable to draw accurate conclusions about the type of defect and its...

7.4.3.- 설치 및 유지 관리 관행

MDU-SCO

커플링 세트

The Set of Couplings, "MDU-SCO", allows to compare the properties of different couplings such as curved tooth, bolt, flange and claw couplings.The vibrational behavior of the different types of couplings is important to draw conclusions about...

7.4.3.- 설치 및 유지 관리 관행

MDU-SBD

벨트 전달 세트

The belt drives are noiseless drive devices, have a long life and require little maintenance provided that its design, assembly and adjustment are correct.The Set of Belt Drive, "MDU-SBD", allows to study the conditions that cause vibrations or...

7.4.3.- 설치 및 유지 관리 관행

MDU-SSDG

기어 결함 세트

The Set to Study Damage in Gears, "MDU-SSDG", allows to study the vibrational behavior of gears with typical defects.For that purpose, gears with tooth defects and gears without defects are included, so a comparative study can be carried out. The...

7.4.3.- 설치 및 유지 관리 관행

MDU-SCM

크랭크 메커니즘 세트

The compressors and pumps frequently use crank and connecting rod mechanisms. The force and mass oscillations cause vibrations in the units.The Set of Crank Mechanism, "MDU-SCM", allows to adjust the stroke, mass compensation and bearing...

7.4.3.- 설치 및 유지 관리 관행

MDU-SSCP

펌프 캐비테이션 세트

Pump cavitation is produced when steam cavities are created within a fluid in which forces act responding to the pressure differences.Cavitation causes noise, damage to components and loss of performance.The Set to Study Cavitation in Pumps,...

7.4.3.- 설치 및 유지 관리 관행

MDU-SSVF

MDU 블로어 진동 세트

In the Blower Vibration Set for MDU, "MDU-SSVF", the vibrations are magnetically induced. It is possible to study three impellers with a different number of movable vanes. It is also possible to study the gyroscopic effect by mounting the flywheel...

7.4.3.- 설치 및 유지 관리 관행

MDU-SEV

전기 기계진동 세트

Among the drive systems are the asynchronous motors, which generate vibrations in machines.This is the case with an asymmetric air gap (space between rotor and stator), in which the magnetic vibrational forces induce torsional and bending...

7.4.3.- 설치 및 유지 관리 관행

MDU-SD

MDU 장치용 변위 센서

Two displacement sensors which, together with the Set of Elastic Shaft ,"MDU-SES", and the Software, Sensors and Control for MDU Unit, "MDU-SSC", allow you to represent subcritical and supercritical shaft orbits in resonance.

연습 및 가이드

매뉴얼에 포함 된 가이드 실기 연습

- Assessment of the vibration state of a machine.

- Measuring the vibrations caused by unbalanced operation ofrigid rotors in 1 and 2 planes.

- Study of the basic essentials of the vibration measurement in shafts and bearings.

- Study of the basic magnitudes and parameters.

- Use of measuring sensors and instruments.

- Understanding the influence of speed and shaft and recorder arrangements.

- Learning to balance rigid shafts in operation and alignment between motor and bearing.

- Understanding and interpreting the frequency spectra.

- Learning about the different vibration signals.

- Applying the FFT analysis correctly.

- Measuring the speed, oscillation travel, oscillation speed and acceleration.

- Learning about the effects of alignment on different types of couplings.

- Learning about the effects of speed on vibration behavior.

- Learning about the effects of the balanced and unbalanced elastic rotor (MDU-SES kit required).

- Study of the variation of a typical vibration behavior (vibration velocity, frequency, amplitude, and phase) due to a fissure (MDU-SRS kit required).

- Identifying cracks and fissures in shafts through acceleration curves and order analysis (MDU-SRS required).

- Identifying a fissure through the variation of a vibration spectrum (MDU-SRS required).

- Estimating the life cycle of a roller bearing (MDU-SRBF required).

- Identifying faulty roller bearings (MDU-SRBF required).

- Checking the effects of roller bearing faults on outer and inner ring, or the roller bearing body on the vibration spectrum (MDU-SRBF required).

- Understanding the effect of ring gear hardness on claw couplings (MDU-SCO required).

- Comparing the curved tooth, bolt, flange or claw couplings (MDU-SCO required).

- Understanding the importance of belt tension in vibration behavior (MDU-SBD required).

- Checking the effect of the eccentricity in pulleys and the speed in vibration behavior (MDU-SBD required).

- Comparison between defective and non-defective belts (MDU-SBD required).

- Understanding and interpreting the frequency spectra in order to differentiate between defective and non-defective belts (MDU-SBD required).

- Identifying defects in the gears according to their vibration behavior (MDU-SSDG required).

- Learning about the effect of the toothed gear, the lubrication used and the wheelbase and the backlash (MDU-SSDG required).

- Identifying wear on the rod and piston (MDU-SCM required).

- Learning about the effect of bearing clearance and impacts (MDU-SCM required).

- Study of the vibrations of a centrifugal pump in operation (MDUSSCPrequired).

- Understanding the cavitation phenomenon in a centrifugal pump (MDU-SSCP required).

- Identifying vibrations caused by the movable vanes in the vibration spectrum (MDU-SSCP required).

- Measuring the pitch frequency between movable vanes (MDU-SSCP required).

- Measuring the blower vibrations (MDU-SSCP required).

- Learning about the effect of an asymmetric air gap on the vibration behavior and the electromagnetic and performance losses (MDU-SEV required).

- Learning about the effect of the electrical windings on vibration behavior (MDU-SEV required).

비슷한 제품

7.4.3.- 설치 및 유지 관리 관행

MDUC

컴퓨터 (PC)에서 제어되는 기계 진단 장치

The Computer Controlled Machine Diagnosis Unit, "MDUC", of EDIBON, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.The Computer...

보완 장비

7.4.3.- 설치 및 유지 관리 관행

ADSG

드라이브, 축 및 기어 정렬 장비

The Drive, Shaft, and Gear Alignment Unit, "ADSG", allows for studying the coupling and uncoupling, maintenance, repair of the related units and checking the operation with the following units:CGA. Combined Gear Assembly Unit.SGA. Spur Gear...

7.4.3.- 설치 및 유지 관리 관행

MDUC

컴퓨터 (PC)에서 제어되는 기계 진단 장치

The Computer Controlled Machine Diagnosis Unit, "MDUC", of EDIBON, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.The Computer...

7.4.3.- 설치 및 유지 관리 관행

MDU-MLB

MDU 장치용 이동식 구조

The Mobile Structure for MDU, "MDU-MLB", is a robust structure designed to quickly and easily assemble the various elements of the MDU Base Unit, "MDU-UB" or the Computer Controlled Machine Diagnosis Unit, "MDUC", and thus assemble a mobile test...

7.4.3.- 설치 및 유지 관리 관행

MDU-SM

MDU 장치용 데스크톱 구조

A bench-top structure consisting of a slotted table with anodized aluminum frames of 1100 x 770 x 820 mm.It has a transparent protective cover that protects against the rotating parts and allows us to observe the different experiments. The cover...

7.4.3.- 설치 및 유지 관리 관행

MDU-SSC

소프트웨어, 센서 및 제어장치를 갖춘 MDU 장치

The aim of the vibration analyzer is to assess the machine diagnosis testing with the different kits related to the vibration interface technology.The system consists of two acceleration sensors, a speed sensor, a measuring amplifier with...

7.4.3.- 설치 및 유지 관리 관행

MDU-BLU

제동 및 하중 장비

The Break and Load Unit, "MDU-BLU", of EDIBON is a magnetic particle brake, a display unit and an electrical control. It is possible to precisely adjust the braking moment. The excitation current is used as a measurement of the braking moment and...

7.4.3.- 설치 및 유지 관리 관행

MDU-SES

탄성 나무 세트

The Set of Elastic Shaft, "MDU-SES", of EDIBON allows to study the behavior of an elastic rotor subjected to imbalance and balance of elastic rotors in operation. It is possible to study the resonance and the phenomena occurred in subcritical and...

7.4.3.- 설치 및 유지 관리 관행

MDU-SRS

균열이 있는 축 세트

It is important that fissures resulting from material fatigue in rotating machines are detected in good time before the breakage occurs, which usually leads to fatal consequences.The Set of Rotating Shaft with Crank, "MDU-SRS", consists of two...

7.4.3.- 설치 및 유지 관리 관행

MDU-SRBF

베어링 결함 세트

To determine the remaining life cycle of a roller bearing and decide on its replacement, the slow variation of the vibration spectrum is analyzed. The spectral distribution will enable to draw accurate conclusions about the type of defect and its...

7.4.3.- 설치 및 유지 관리 관행

MDU-SCO

커플링 세트

The Set of Couplings, "MDU-SCO", allows to compare the properties of different couplings such as curved tooth, bolt, flange and claw couplings.The vibrational behavior of the different types of couplings is important to draw conclusions about...

7.4.3.- 설치 및 유지 관리 관행

MDU-SBD

벨트 전달 세트

The belt drives are noiseless drive devices, have a long life and require little maintenance provided that its design, assembly and adjustment are correct.The Set of Belt Drive, "MDU-SBD", allows to study the conditions that cause vibrations or...

7.4.3.- 설치 및 유지 관리 관행

MDU-SSDG

기어 결함 세트

The Set to Study Damage in Gears, "MDU-SSDG", allows to study the vibrational behavior of gears with typical defects.For that purpose, gears with tooth defects and gears without defects are included, so a comparative study can be carried out. The...

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정