At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

MDU-SSC 소프트웨어, 센서 및 제어장치를 갖춘 MDU 장치

혁신적인 시스템

The aim of the vibration analyzer is to assess the machine diagnosis testing with the different kits related to the vibration interface technology.

관련 뉴스

일반적인 설명

The aim of the vibration analyzer is to assess the machine diagnosis testing with the different kits related to the vibration interface technology.

The system consists of two acceleration sensors, a speed sensor, a measuring amplifier with adjustable amplification degree, a USB box and the analysis software.

The analysis software has the following features: two-channel oscilloscope (studies in the time domain), two-channel spectrum analyzer (studies in the frequency domain), vibration intensity gauge, analysis of shock effects and damage in roller bearings, filter for acceleration curve recording, orbit representation and module for single or dual plane balancing of rigid rotors in operation.

Thanks to the software, it is possible to compare the effectiveness of vibration signals by applying various analysis methods and by determining the advantages and disadvantages of different techniques. Each connection unit includes a 1x, 10x, 100x amplifier, with 16 analog input channels, 4 analog output channels, 4 digital input channels and 4 output channels, which will make possible the coupling of the sensors.

The optional connection of the additional recommended element, the Displacement Sensors for MDU Unit, "MDU-SD".

This unit is connected via USB.

It can be used both in a laptop or a computer.

Motor control (MDU-UB) and brake control (MDU-BLU) are optional.

보완 장비

7.4.3.- 설치 및 유지 관리 관행

ADSG

The Drive, Shaft, and Gear Alignment Unit, "ADSG", allows for studying the coupling and uncoupling, maintenance, repair of the related units and checking the operation with the following units:CGA. Combined Gear Assembly Unit.SGA. Spur Gear...

7.4.3.- 설치 및 유지 관리 관행

MDUC

컴퓨터 (PC)에서 제어되는 기계 진단 장치

The Computer Controlled Machine Diagnosis Unit, "MDUC", of EDIBON, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.The Computer...

7.4.3.- 설치 및 유지 관리 관행

MDU

기계 진단

The family of Machine Diagnosis Unit, "MDU", of Edibon, allows you to perform vibration measurement practical exercises, measuring the displacement, velocity and acceleration of vibrations in the time-frequency range.The MDU Base Unit, "MDU-UB",...

7.4.3.- 설치 및 유지 관리 관행

MDU-MLB

MDU 장치용 이동식 구조

The Mobile Structure for MDU, "MDU-MLB", is a robust structure designed to quickly and easily assemble the various elements of the MDU Base Unit, "MDU-UB" or the Computer Controlled Machine Diagnosis Unit, "MDUC", and thus assemble a mobile test...

7.4.3.- 설치 및 유지 관리 관행

MDU-SM

MDU 장치용 데스크톱 구조

A bench-top structure consisting of a slotted table with anodized aluminum frames of 1100 x 770 x 820 mm.It has a transparent protective cover that protects against the rotating parts and allows us to observe the different experiments. The cover...

7.4.3.- 설치 및 유지 관리 관행

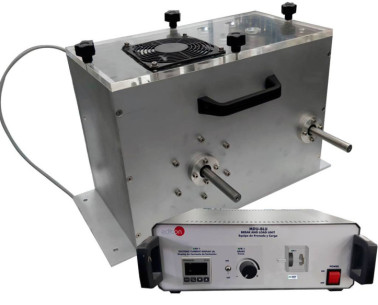

MDU-BLU

제동 및 하중 장비

The Break and Load Unit, "MDU-BLU", of EDIBON is a magnetic particle brake, a display unit and an electrical control. It is possible to precisely adjust the braking moment. The excitation current is used as a measurement of the braking moment and...

7.4.3.- 설치 및 유지 관리 관행

MDU-SES

탄성 나무 세트

The Set of Elastic Shaft, "MDU-SES", of EDIBON allows to study the behavior of an elastic rotor subjected to imbalance and balance of elastic rotors in operation. It is possible to study the resonance and the phenomena occurred in subcritical and...

7.4.3.- 설치 및 유지 관리 관행

MDU-SRS

균열이 있는 축 세트

It is important that fissures resulting from material fatigue in rotating machines are detected in good time before the breakage occurs, which usually leads to fatal consequences.The Set of Rotating Shaft with Crank, "MDU-SRS", consists of two...

7.4.3.- 설치 및 유지 관리 관행

MDU-SRBF

베어링 결함 세트

To determine the remaining life cycle of a roller bearing and decide on its replacement, the slow variation of the vibration spectrum is analyzed. The spectral distribution will enable to draw accurate conclusions about the type of defect and its...

7.4.3.- 설치 및 유지 관리 관행

MDU-SCO

커플링 세트

The Set of Couplings, "MDU-SCO", allows to compare the properties of different couplings such as curved tooth, bolt, flange and claw couplings.The vibrational behavior of the different types of couplings is important to draw conclusions about...

7.4.3.- 설치 및 유지 관리 관행

MDU-SBD

벨트 전달 세트

The belt drives are noiseless drive devices, have a long life and require little maintenance provided that its design, assembly and adjustment are correct.The Set of Belt Drive, "MDU-SBD", allows to study the conditions that cause vibrations or...

7.4.3.- 설치 및 유지 관리 관행

MDU-SSDG

기어 결함 세트

The Set to Study Damage in Gears, "MDU-SSDG", allows to study the vibrational behavior of gears with typical defects.For that purpose, gears with tooth defects and gears without defects are included, so a comparative study can be carried out. The...

품질

판매 후 서비스

쿠키 기본 설정

쿠키 기본 설정