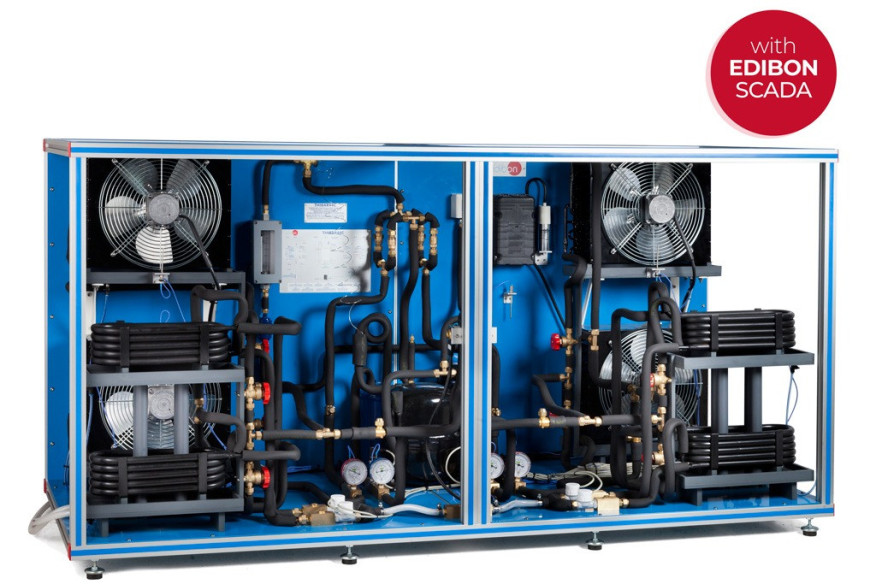

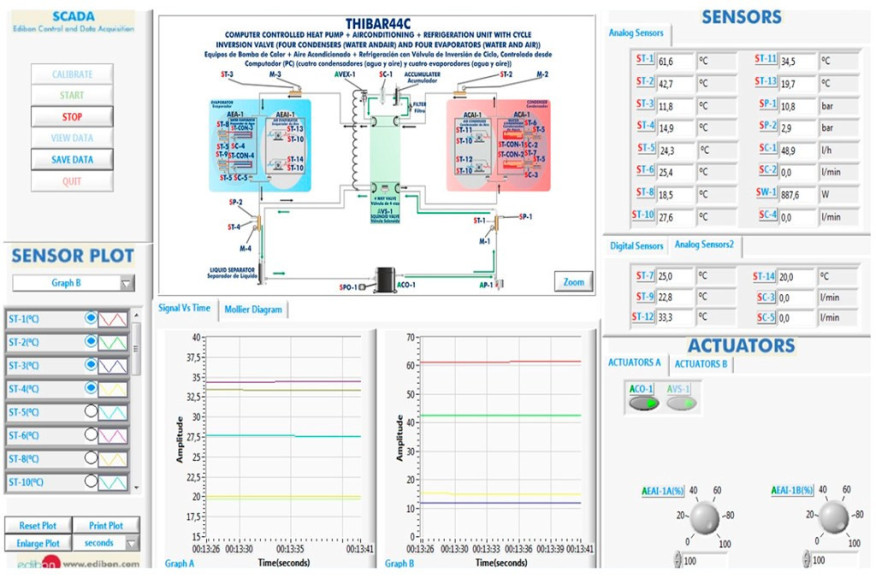

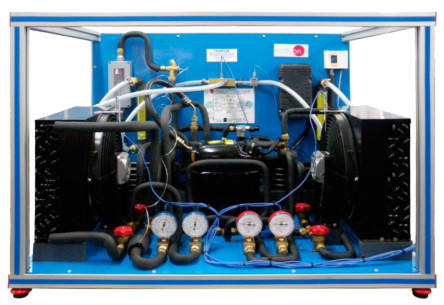

The Computer Controlled Rerversible Heat Pump + Air Conditioning + Refrigeration with 4 Condensers and 4 Evaporators (Water/Air),"THIBAR44C", has as aim introduce the student to the study of the heat pumps, air-conditioning and cooling, as well as to analyze anddetermine the operation typical parameters of the unit depending on the two types of fluids used in the evaporation and condensationprocesses (air and water).

This unit can have different applications, depending on the type of cold focus or hot focus used in theevaporation and condensation processes.

This unit consists of the following stages:

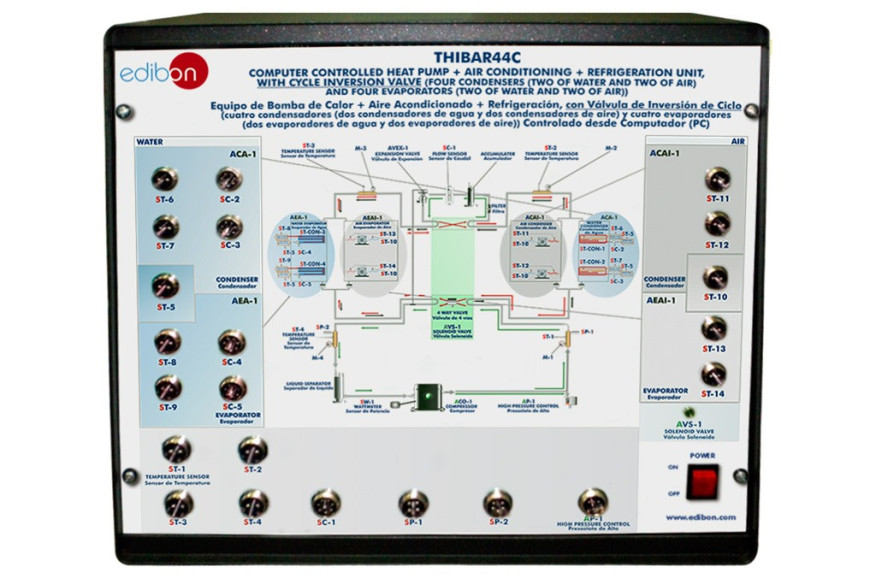

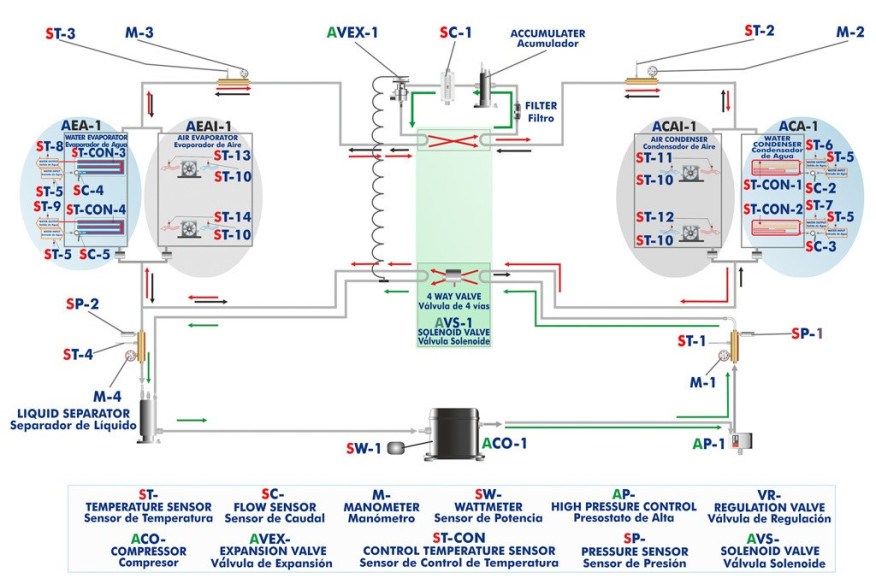

- Compression: this stage begins when the coolant enters the compressor. This coolant is compressed, increasing its pressure and temperature. To measure these variables the unit includes a pressure sensor, a manometer and a temperature sensor.

- Condensation: the coolant has two possibilities, to be diverted towards the air condenser or towards the water condenser. The coolant transfers its heat to the water (or to the air) that flows through the condenser. At the end of this stage, the pressure and temperature of the coolant are measured with a manometer and a temperature sensor.

- Expansion: the coolant flows through an accumulator and a filter, to retain particles of condensate, and a flow sensor. Then it is directed to the expansion valve, which causes a pressure and temperature drop in the coolant. At the end of this stage the pressure and temperature of the coolant are measured with a manometer and a temperature sensor.

- Evaporation: the coolant has two possibilities, to be diverted towards the air evaporator or towards the water evaporator. The coolant absorbs the heat of the water (or the air) that flows through the evaporator. At the end of this stage the pressure and temperature of the coolant are measured with a pressure sensor, a manometer and a temperature sensor. Finally, the coolant passes through a liquid separator to retain liquid particles before being directed to the compressor.

The condensers and evaporators have different sensors to measure the most important parameters (temperatures and flows). In addition, the unit includes a high pressure switch to avoid overpressure in the unit and a four-way valve to change the direction of the coolant.

The four-way valve (or cycle inversion valve) allows to obtain different combinations of Heat Pump, Air Conditioning and Cooling in only one unit.

Preferências de cookies

Preferências de cookies