QALFC Equipamento de Adsorção de Leito Fixo, Controlado por Computador (PC)

SISTEMAS INOVADORES

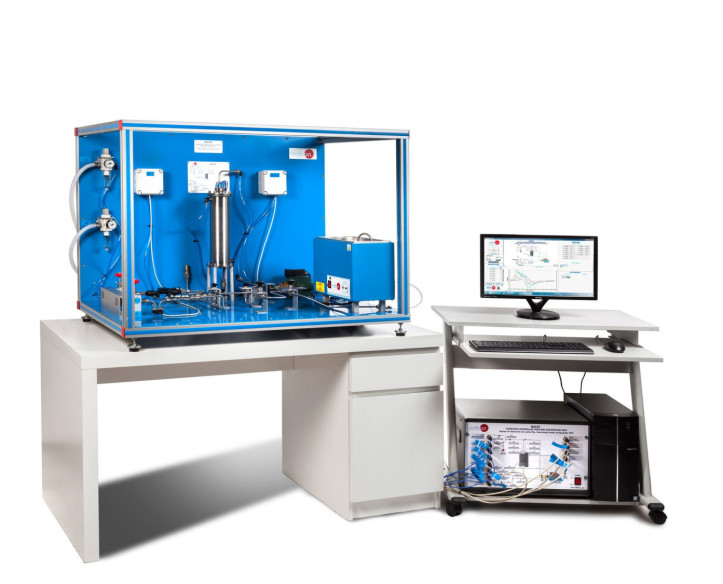

The Computer Controlled Fixed Bed Adsorption Unit, "QALFC", has been designed by EDIBON to demonstrate the gas adsorption phenomenon using a fixed adsorption column.

Expansões

LABORATÓRIOS

NOTÍCIAS RELACIONADAS

Descrição Geral

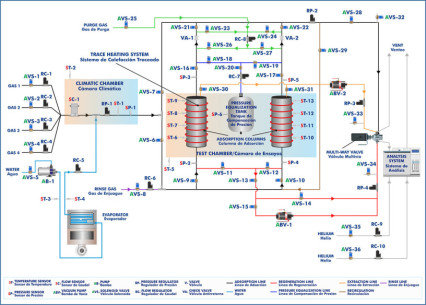

The Computer Controlled Fixed Bed Adsorption Unit, "QALFC", has been designed by EDIBON to demonstrate the gas adsorption phenomenon using a fixed adsorption column. The overall objective of this unit is to analyze the behavior of the adsorption breakthrough and desorption elution curves associated with the separation of CO₂ from Helium using activated carbon. The equilibrium adsorption capacity of this activated carbon will be determined from this analysis and used to model the experimental breakthrough and elution curves.

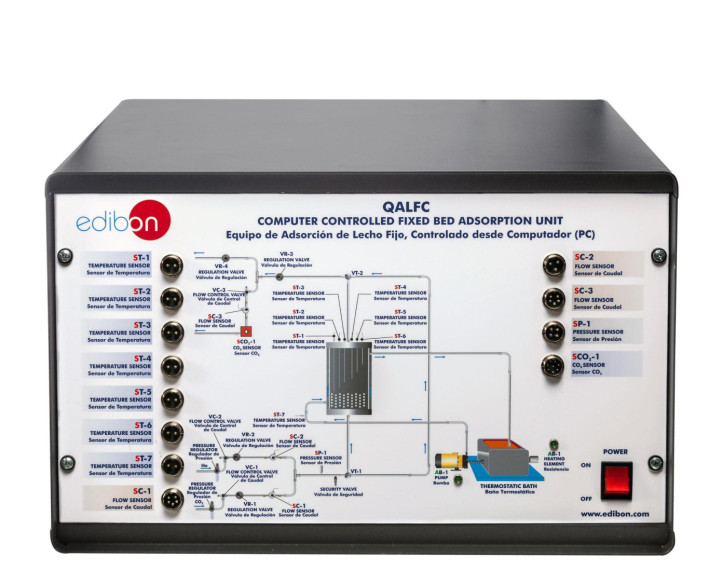

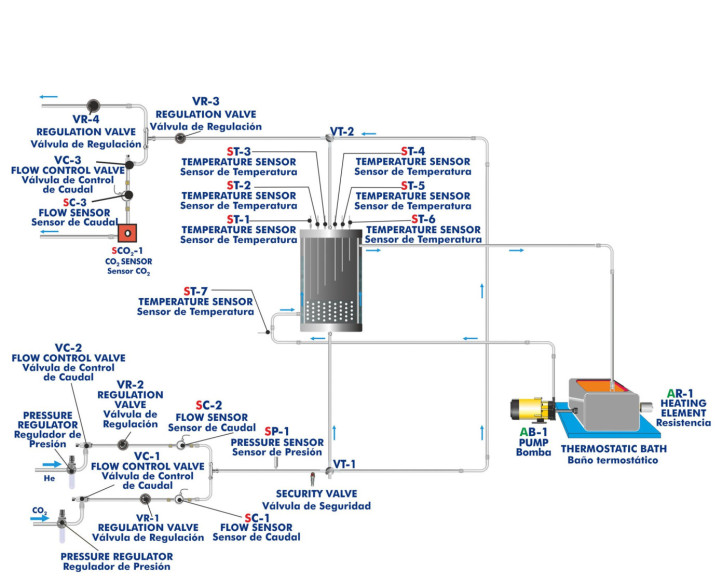

The gas mixture (composed by CO₂ and Helium) is fed from compressed gas cylinders to the column with two pressure regulators. Two flow sensors and two regulation valves are included to measure and regulate the CO₂ and Helium inlet flows. The lines include two flow control valves to limit the CO₂ and Helium flow.

The fixed bed adsorption column is jacketed for the purpose of thermal control and the adsorbent, activated carbon, is packed. Six temperature sensors with different lengths are located inside the column to measure the adsorption and desorption temperatures.

A column bypass is included for system calibration purposes. This column has two 3-way directional valves, which divert the gas stream between the fixed bed adsorption column and the bypass. A valve at the column's outlet is used to control the pressure in the circuit. This pressure is measured by a pressure sensor. The unit is protected against overpressure by a security valve.

The column is thermally controlled by hot water, which is heated by a system consisting of a thermostatic bath with a heating element and a water pump. An additional temperature sensor is located in the thermostatic bath.

The gas mixture, after passing through the column or the bypass, is divided. A part of the gas mixture passes through an infrared CO₂ sensor to measure the CO₂ concentration at the column or bypass outlet. A third flow sensor measures the flow entering the CO₂ sensor and a regulation valve regulates the gas mixture flow in the flow sensor. This line includes a flow control valve to limit the gas mixture flow. The rest of the gas mixture is discharge to the atmosphere.

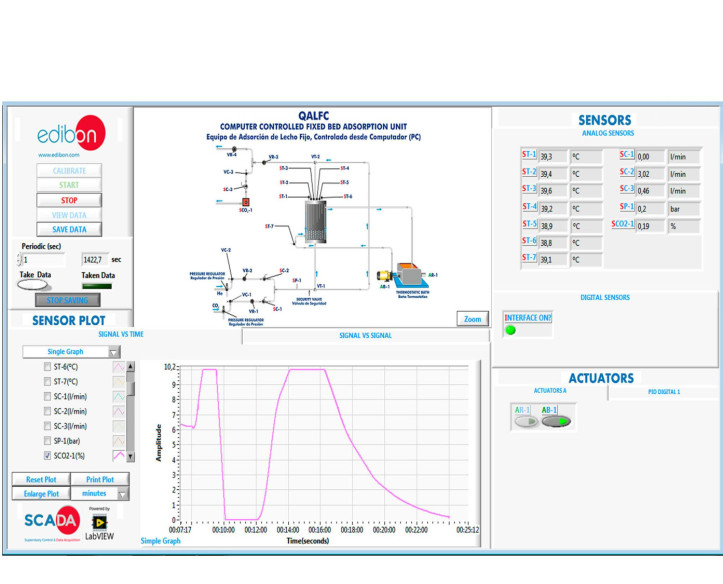

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

EXERCÍCIOS E PRÁTICAS GUIADAS

EXERCÍCIOS PRÁTICOS GUIADOS INCLUÍDOS NO MANUAL

- Study of the Solute Movement Theory model described by the adsorption-desorption process.

- Study of adsorption/desorption processes under different operational conditions such as temperature, pressure, flow rate and molar fraction.

- Study of the breakthrough curves of CO2 and the temperature profiles during the adsorption/desorption processes.

- Study of the quasi-isothermal regime at low concentrations and pressures. Study of the effect of these variables.

- Familiarization with the formation of the compressive and dispersive fronts in adsorption processes.

- Sensors calibration.

EXERCÍCIOS MAIS PRÁTICOS A SEREM FEITOS COM A UNIDADE

- Obtaining of the adsorption equilibrium isotherm of CO2 from the desorption curve.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control.This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the QALFC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the QALFC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user

EQUIPAMENTOS COMPLEMENTARES

Coluna de Absorção de Gases

Coluna de Absorção de Gases de Parede Úmida, Controlada por Computador (PC)

Equipamento de Laboratório de Adsorção por Pressão Oscilante

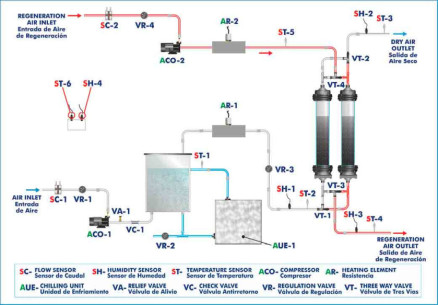

Equipamento de Secagem do Ar por Adsorção, Controlado por Computador (PC)

Planta de Lavagem de Gases, Controlada por Computador (PC)

Equipamento de Estudo de Fluxo em Colunas Empacotadas, Controlado por Computador (PC)

Equipamento de Adsorção, Controlado por Computador (PC)

Qualidade

Serviço pós-venda

Preferências de cookies

Preferências de cookies