At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

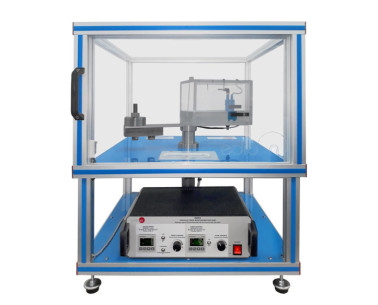

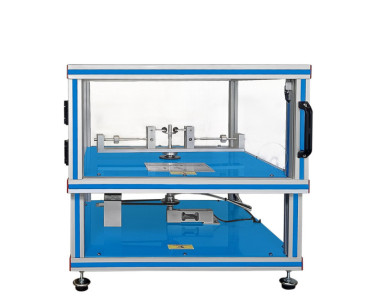

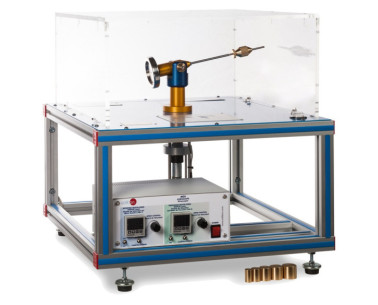

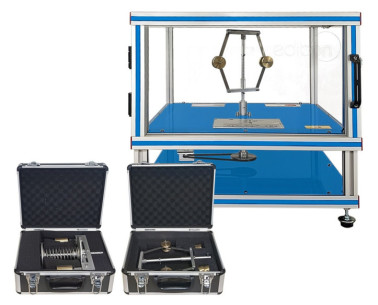

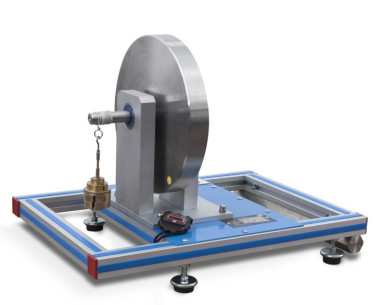

We have returned to the Cfmi_togo to install some of our equipment. These units belong mainly to the areas of Environment, Chemical Engineering, Thermodynamics & Thermotechnics, Energy and Mechanics.

We recently had the honor of installing a complete laboratory at the Centre de formation et des métiers (CFMI) in Togo (Africa).This complete laboratory now has the following EDIBON units

Are you a teacher or do you work as an engineering researcher? EDIBON offers courses for teachers and #research staff. Take a look at the course Basic Mechanics and learn about #forces and vectors. #DiscoverEdibon #Engineering.

Preferências de cookies

Preferências de cookies