At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-MACT Estação Pneumática de Manipulação e Esteira de Transporte

SISTEMAS INOVADORES

The Pneumatic Handling and Conveyor Belt Workstation, "AE-PLC-MACT", has been designed by EDIBON to let students getting familiar with automatic systems with conveyor systems, including PLC, industrial sensors, and pneumatic actuators.

NOTÍCIAS RELACIONADAS

Descrição Geral

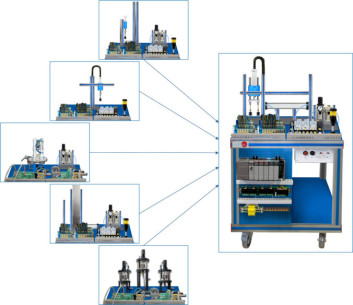

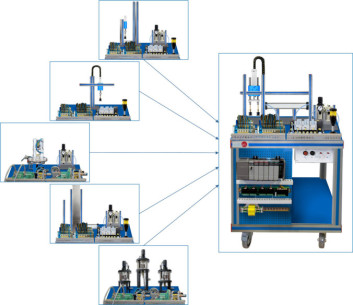

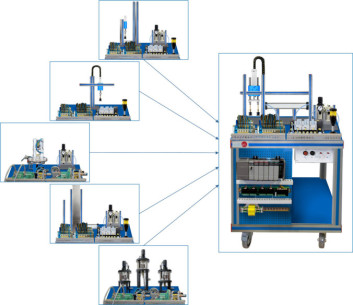

The Pneumatic Handling and Conveyor Belt, "AE-PLC-MACT", is an automatic handling station with a conveyor system commanded by a PLC. The "AE-PLC-MACT" is composed of a pneumatic handling system that uses vacuum technology to move pieces from the input area to the conveyor system or vice versa.

The "AE-PLC-MACT" includes a "modified AE-PLC-PAN" for this system, which incorporates a Panasonic PLC, analog and digital inputs and outputs, an HMI interface, a test module, a fault injection box, an Ethernet switch, and a main power supply. The "modified AE-PLC-PAN" for this system is shown in the figure below.

The "AE-PLC-MACT" pneumatic station consists of the following components:

DC conveyor belt with servomotor, allowing control of speed, position, and direction of rotation.

Part sensors to detect parts and stop the belt to place another part.

Pneumatic system for moving parts using vacuum technology to pick them up.

PLC that automates the process, included in the "modified AE-PLC-PAN".

Removable key switch to turn the equipment on or off.

Control panel with a mushroom-type stop switch, stop and start buttons, manual and automatic modes, and indicator lights. Included in the "modified AE-PLC-PAN".

EXERCÍCIOS E PRÁTICAS GUIADAS

EXERCÍCIOS PRÁTICOS GUIADOS INCLUÍDOS NO MANUAL

- Introduction to Flexible Manufacturing System (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Introduction to vacuum technology.

- Study of the sensor detection.

- Configuration of a pneumatic application.

- Manual control of a handling system.

- Automatic control of a handling system.

- Modification of the parameters of the handling process.

- Optimization of process time.

- Study and analysis of the faults inserted in the process with the fault generation module.

EQUIPAMENTOS SIMILARES DISPONÍVEIS

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-MAE

The "AE-PLC-MAE" is an electrical handling system commanded by a PLC. The "AE-PLC-MAE" is composed of a two axis electrical manipulator with a pneumatic gripper to transport the pieces from the input pieces holder to the corresponding position,...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-MAN

Estação Pneumática de Manipulação

The "AE-PLC-MAN" is a pneumatic handling workstation commanded by a PLC, which performs handling and sorting functions.The workstation identify the color of the input pieces at the input pieces area, once the color is identified, the station take...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-MPS

Estação de Manipulação de Peças

The "AE-PLC-MPS", Pieces Manipulator Workstation, is a unit that works with pneumatics, electro-pneumatics and vacuum technologies.The "AE-PLC-MPS" performs the following operation: moving a piece from one position to another by using suction pads...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-T

Estação de Transporte Linear

The "AE-PLC-T" is a linear transporting system, which moves the pallets, that carries the pieces, along the system. The unit is configured in a closed loop conveyor powered by an electrical motor, the whole system is commanded by a PLC. The...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-SPO

Estação de Posicionamento

The Positioning Workstation, "AE-PLC-SPO", has been designed by EDIBON to studiy three-axis positioners for computer integrated manufacturing systems. It sorts incoming pieces based on material and dimensions using a PLC-controlled manipulator.The...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-CTCA

Estação de Esteira Transportadora CA

The "AE-PLC-CTCA" is an AC powered conveyor system commanded by a PLC. The "AE-PLC-CTCA" is composed by a conveyor, 4 position sensors to stop the conveyor at different positions, motor positioner, AC motor driver and three-phased motor to a...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-CTCC

Estação de Transportador de Corrente Contínua

The DC Conveyor Belt Workstation, "AE-PLC-CTCC", explores DC conveyor system management, including piece classification. It features industrial components like PLC, sensors, etc., enabling control of an automatic DC-powered conveyor system with...

EQUIPAMENTOS COMPLEMENTARES

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-MPS

Estação de Manipulação de Peças

The "AE-PLC-MPS", Pieces Manipulator Workstation, is a unit that works with pneumatics, electro-pneumatics and vacuum technologies.The "AE-PLC-MPS" performs the following operation: moving a piece from one position to another by using suction pads...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-T

Estação de Transporte Linear

The "AE-PLC-T" is a linear transporting system, which moves the pallets, that carries the pieces, along the system. The unit is configured in a closed loop conveyor powered by an electrical motor, the whole system is commanded by a PLC. The...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-SPO

Estação de Posicionamento

The Positioning Workstation, "AE-PLC-SPO", has been designed by EDIBON to studiy three-axis positioners for computer integrated manufacturing systems. It sorts incoming pieces based on material and dimensions using a PLC-controlled manipulator.The...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-MAE

Estação Elétrica de Manipulação

The "AE-PLC-MAE" is an electrical handling system commanded by a PLC. The "AE-PLC-MAE" is composed of a two axis electrical manipulator with a pneumatic gripper to transport the pieces from the input pieces holder to the corresponding position,...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-MAN

Estação Pneumática de Manipulação

The "AE-PLC-MAN" is a pneumatic handling workstation commanded by a PLC, which performs handling and sorting functions.The workstation identify the color of the input pieces at the input pieces area, once the color is identified, the station take...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-CTCA

Estação de Esteira Transportadora CA

The "AE-PLC-CTCA" is an AC powered conveyor system commanded by a PLC. The "AE-PLC-CTCA" is composed by a conveyor, 4 position sensors to stop the conveyor at different positions, motor positioner, AC motor driver and three-phased motor to a...

6.2.5.4.- APLICAÇÕES DE ESTAÇÕES DE TRABALHO DE MANIPULAÇÃO DE PEÇAS

AE-PLC-CTCC

Estação de Transportador de Corrente Contínua

The DC Conveyor Belt Workstation, "AE-PLC-CTCC", explores DC conveyor system management, including piece classification. It features industrial components like PLC, sensors, etc., enabling control of an automatic DC-powered conveyor system with...

Qualidade

Serviço pós-venda

Preferências de cookies

Preferências de cookies