In a world where climate change represents one of the greatest threats to our future, carbon dioxide (CO2) adsorption has become an urgent priority. The increasing concentration of CO2 in the atmosphere, primarily driven by human activities such as fossil fuel combustion and deforestation, has...

At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

In a world where energy demand continues to rise and non-renewable resources are rapidly depleting, the need for sustainable, environmentally friendly solutions has never been more urgent. The circular economy and the use of organic biomass to produce biofuels are emerging as key answers to...

A Captura Direta de Ar (DAC) é uma tecnologia inovadora que remove o CO₂ diretamente do ar usando reações químicas com solventes líquidos ou absorventes sólidos. Apesar dos desafios, como altos custos e consumo de energia, a DAC oferece uma solução potencial para reduzir as concentrações de CO₂...

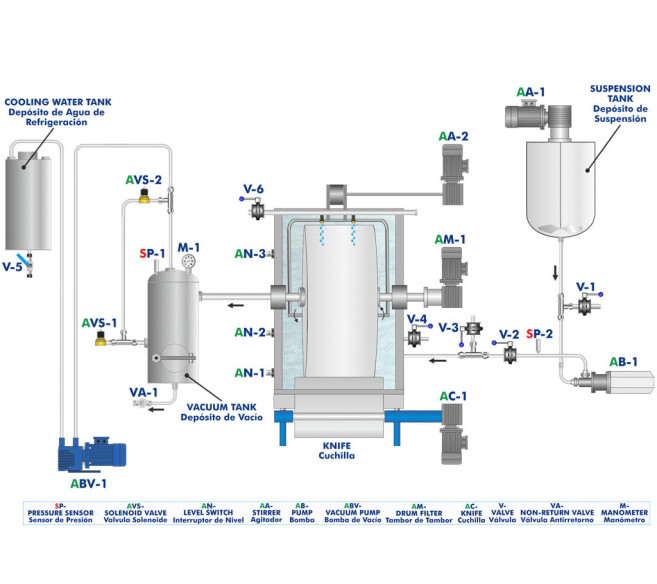

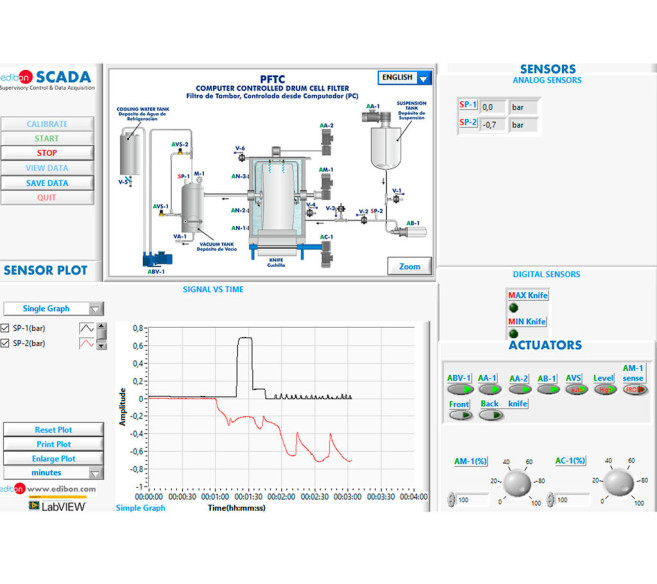

Instalações de Tratamento de Águas Residuais

Enquanto as estações de tratamento de água potável se concentram em fornecer água potável segura, as instalações de tratamento de águas residuais lidam com o tratamento da água usada antes de ser liberada novamente no meio ambiente.

Essas instalações...

Preferências de cookies

Preferências de cookies