SCE Simulador de Regulagem e Controle de Centrais Elétricas, Controlado por Computador (PC)

SISTEMAS INOVADORES

The SCE equipment designed by EDIBON allows to study the modeling and simulation process of the electrical generation of a power plant as well as the verification of the model against the real system.

Expansões

LABORATÓRIOS

NOTÍCIAS RELACIONADAS

Descrição Geral

Unit designed to simulate the regulation behaviour of a hydroelectric generating station, as a didactic application with different aspects ofregulation, control and simulation.

It is possible to work with this unit in 2 ways:

- REAL mode (continuous or transient analysis).

- SIMULATED mode.

The unit consists mainly of an interface for the conditioning of input and output signals. For its part, this one will be connected to thecomputer (through a SCSI wire and a data acquisition board) and to the two subsystems that we try to control:

- Gate subsystem.

- Turbine-generator subsystem.

The unit has (in the interface) some switches to establish different loads to the generator output and different conditions of the real system.This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a DataAcquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and allparameters involved in the process.

EXERCÍCIOS E PRÁTICAS GUIADAS

EXERCÍCIOS PRÁTICOS GUIADOS INCLUÍDOS NO MANUAL

- Modelization of the motor as a standard motor.

- Modelization of the motor with the constants corrections of themathematical model.

- Calculation of the dynamos speed constant.

- Obtaining of the transient responses of the gate motor.

- Obtaining of the transient response of the turbine motor.

- Obtaining of the transient response of the gate simulated motor.

- Obtaining of the transient response of the turbine simulatedmotor.

- Comparative analysis of the transient response of the turbinereal motor vs the transient response of the simulated motor forresistive load.

- Comparative analysis of the transient response of the turbinereal motor vs the transient response of the simulated motor forcapacitive load.

- Comparative analysis of the transient response of the turbinereal motor vs the transient response of the simulated motor forinductive load.

- Comparative analysis of the response of the gate real motorvs the response of the gate simulated motor for continuous(manually from the computer) control signals.

- Comparative analysis of the response of the gate real motor vsthe response of the gate simulated motor for sinusoidal controlsignals.

- Comparative analysis of the response of the gate real motorvs the response of the gate simulated motor for square controlsignals.

- Comparative analysis of the response of the gate real motor vsthe response of the gate simulated motor for triangular controlsignals.

- Comparative analysis of step response between real motor andsimulated motor (gate or turbine).

EXERCÍCIOS MAIS PRÁTICOS A SEREM FEITOS COM A UNIDADE

- Many students view results simultaneously. To view all results in real time in the classroom by means of aprojector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains: proportional, integral, derivative parameters, etc. in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industrieseven to other Technical Education Institutions.

- Several other exercises can be done and designed by the user.

EQUIPAMENTOS COMPLEMENTARES

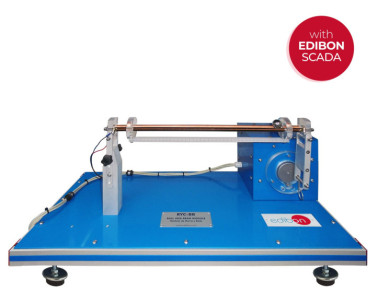

Equipamento Modular de Regulação e Controle, Controlado por Computador (PC)

Equipamento de Estudo de Regulação e Controle, Controlado por Computador (PC)

Equipamento de Controlo e Regulação PID de um Sistema Barra-Bola

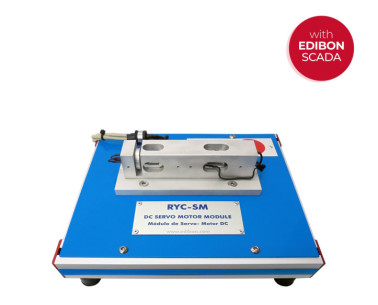

Equipamento de Controlo e Regulação PID de um Servomotor CC

Equipamento de Controlo e Regulação PID da Temperatura de um Caudal de Ar

Equipamento de Controlo e Regulação PID de um Pêndulo Invertido

Equipamento de Controlo e Regulação PID de Levitação Magnética

Equipamento de Controlo e Regulação PID da Temperatura de um Caudal de Água

Equipamento de Controlo e Regulação PID da Temperatura

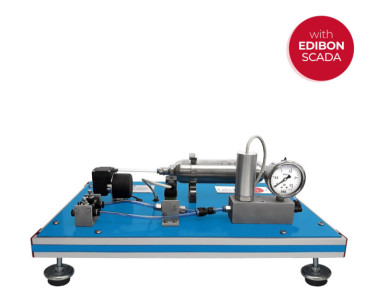

Equipamento de Controlo e Regulação PID do Nível de Pressão

Equipamento de Controlo e Regulação PID de Nível

Qualidade

Serviço pós-venda

Preferências de cookies

Preferências de cookies