TRAC Оборудование для абсорбционного охлаждения, управляемое компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

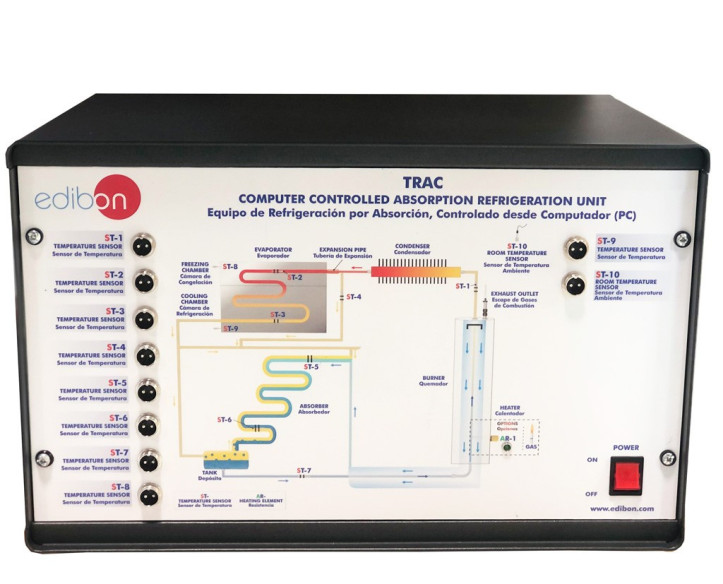

The Computer Controlled Absorption Refrigeration Unit, "TRAC", designed by EDIBON, is a complete laboratory unit for the demonstration of absorption refrigeration.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Absorption Refrigeration Unit, "TRAC", designed by EDIBON, is a complete laboratory unit for the demonstration of absorption refrigeration.

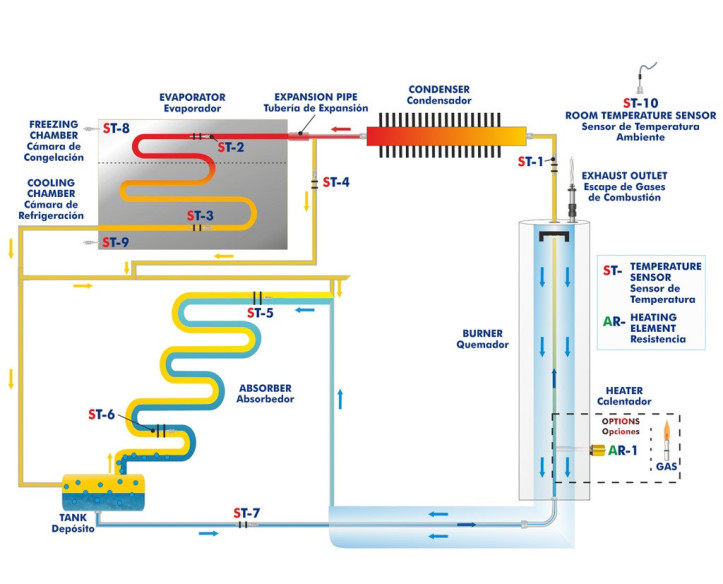

This unit is provided with a dual power source (heat source) of LPG and electricity. A pressure regulator to adapt the gas to the corresponding inlet pressure (30 – 50 mbar) is supplied for the operation with LPG.

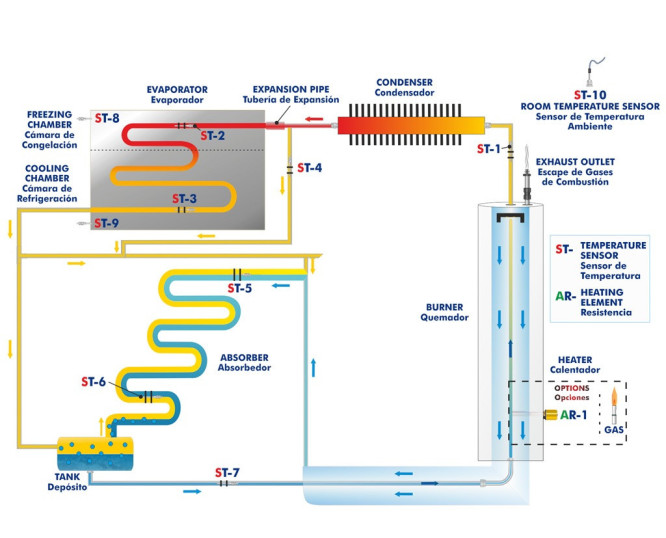

The fluid used in the refrigeration cycle of the "TRAC" unit is a solution of water and ammonia (NH3), being ammonia the refrigerant and water the absorbent. An important advantage is that these agents are totally innocuous for the environment. The cycle uses the great affinity of ammonia with the water, being the ammonia used as refrigerant since it is easily absorbed by water.

The water and ammonia solution is heated at a high pressure in the generator or heater. Two substances are separated then by boiling: on one hand, vapour with a high concentration of ammonia, called concentrated solution, and on the other hand, a liquid solution with a low concentration of ammonia, called diluted or poor solution.

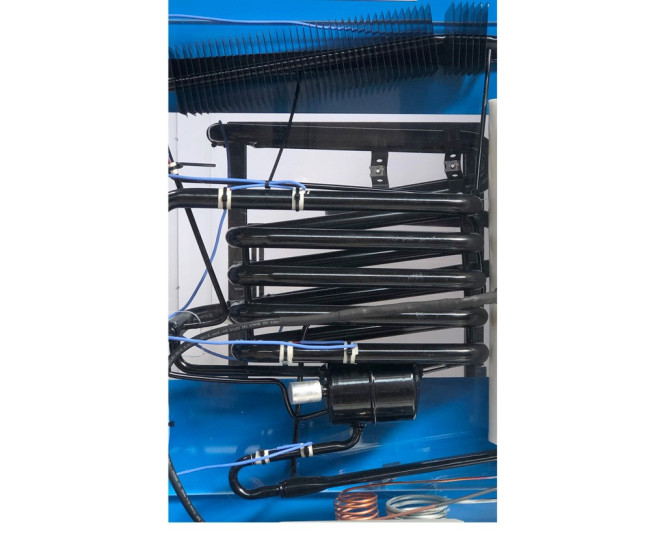

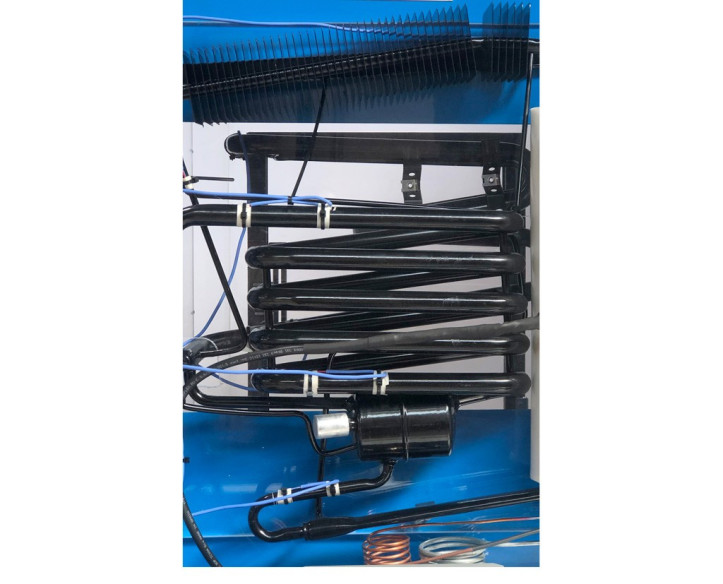

Vapour passes through a condenser (finned exchanger) where it is cooled until it condenses and passes to liquid state, reducing its temperature.

This ammonia concentrated solution enters a heat exchanger, where it is further cooled and its pressure is reduced to enter the evaporator.

Due to this pressure difference, it is evaporated at a low temperature.

The unit includes a tank for the absorber, where the solution rich in ammonia in liquid state formed by the absorber and the ammonia vapour from the evaporator stay together.

The absorber makes it possible to obtain a low pressure in the evaporator, so that the refrigerant (ammonia) boils at a lower temperature, taking the required heat from the water, reducing its temperature.

The liquid solution rich in ammonia coming from the absorber is heated in the generator to separate the pure ammonia vapours and the water (absorber). Ammonia vapours go to the condenser and the poor solution goes to the absorber, where the absorption of the ammonia in vapour state is generated again.

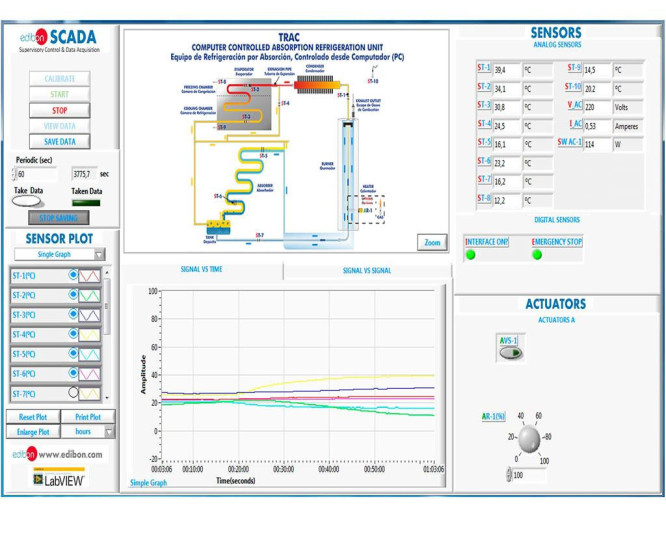

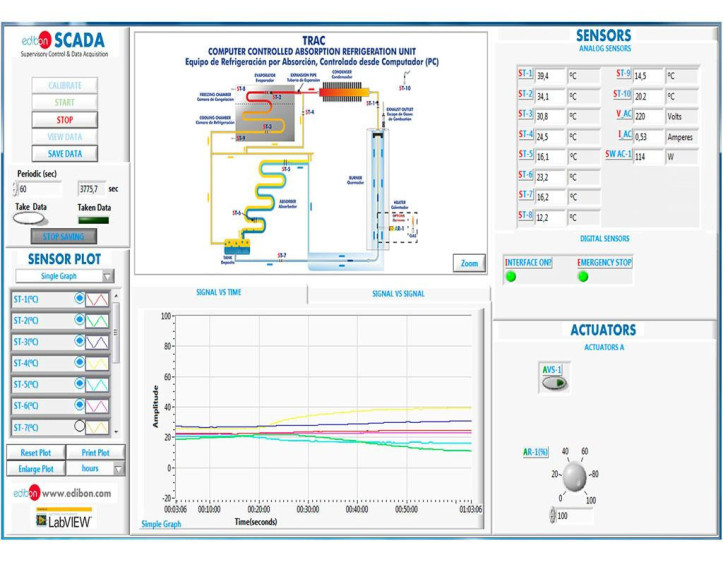

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Demonstration of the refrigeration process.

- Demonstration of the vapour absorption refrigeration cycle and visualization of the most important processes.

- Familiarisation with the individual components of the absorption refrigeration unit.

- Operation of the gas absorption refrigeration unit using either an electric element or LPG as the heat source.

- Comparison of the refrigeration temperature obtained using LPG or an electrical element as heat source.

- Measurement of the electrical power.

- Influence of the electrical power in the refrigeration temperature obtained.

- Measurement of the temperature in the main points of the absorption refrigeration process.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TRAC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TRAC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Программируемый стенд башенного охладителя, управляемый с ПК

Программируемый с компьютера стенд Башенного Охладителя

Оборудование для демонстрации цикла охлаждения, управляемое компьютером (ПК)

Оборудование для демонстрации цикла охлаждения

Оборудование для абсорбционного охлаждения

Регулирование Мощности и Отказы в Установках Охлаждения, Управляемое компьютером (ПК)

Оборудование для охлаждения с вихревой трубой, управляемое компьютером (ПК)

Термоэлектрический тепловой насос, управляемый с ПК

Оборудование для простого компрессионного холодильного контура

Тепловой насос + кондиционер + обратное охлаждение с 2 конденсаторами и 2 испарителями (вода/воздух), управляемое с ПК

Тепловой насос + кондиционер + обратное охлаждение с 2 конденсаторами и 2 испарителями (вода/воздух)

Тепловой насос + кондиционер + обратное охлаждение с 4 конденсаторами и 4 испарителями (вода/воздух), управляемое с ПК

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie