TACC Оборудование для кондиционирования воздуха с климатической камерой и водяным охладителем, управляемое ПК

ИННОВАЦИОННЫЕ СИСТЕМЫ

The objective of the Computer Controlled Air Conditioning Unit with Climatic Chamber and Water Chiller, "TACC", designed by EDIBON is to introduce the student into the complex world of air conditioning systems, as well as to study and determine the optimal parameters to obtain comfortable environments, the air humidity limit, psychrometric charts, heat transfer, etc.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Air Conditioning Unit with Climatic Chamber and Water Chiller, "TACC", is an actual air conditioning system with climatic chamber suitable for people and allows the study of the influence of different operation modes of the system on human comfort.

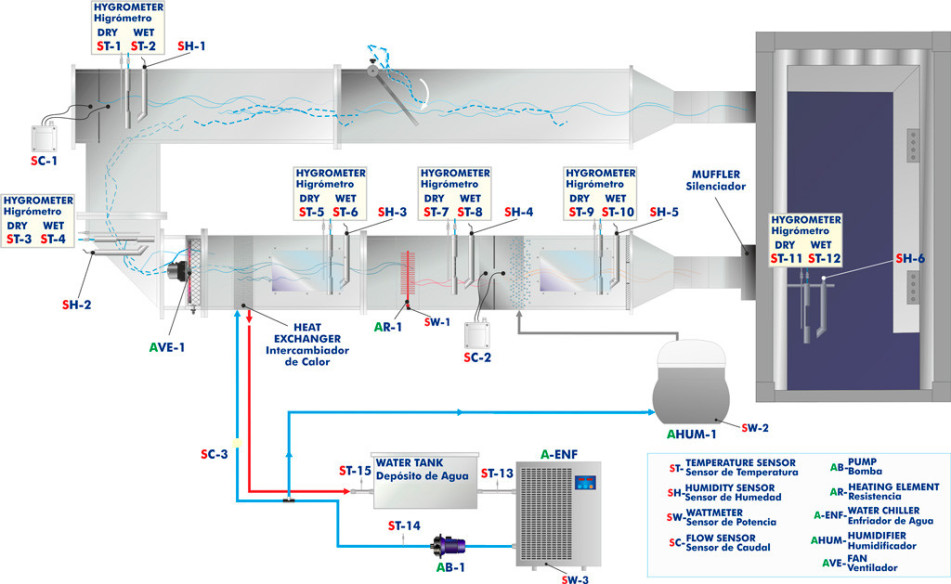

It mainly consists of a square section tunnel made of stainless steel with several windows that allow the visualization of the process.

There is a computer controlled variable speed fan in one end to introduce air in the duct.

After being impelled, the air passes through a heat exchanger (air-water) to cool the air, thus increasing its relative humidity till reaching the dew point and partially removing the content of water in the air. There is a computer controlled water chiller, a water tank and a recycling pump at the bottom of the unit. The pump will impel the generated cold water through the heat exchanger and it will gain the heat given by the air. There are temperature and flow sensors that enable the user to make energy balances and quantify the cooling capacity in the heat exchanger and the water chiller.

Then, the air passes through a computer controlled electric heating element to adjust the air temperature and decrease the relative humidity to the desired values.

Finally, the air crosses a computer controlled humidifier that increases the humidity content in the air.

Air leaving the duct enters a climatic chamber suitable for persons, where the comfort feeling in function of the set parameters can be checked.

After leaving the chamber, air can be recycled to the air conditioning duct by an adjustable duct, which enables to work with outside air or with recycled air. Both flows are indicated by two air flow sensors.

To control and observe the temperature and humidity variables, the unit has 6 strategically located measuring points (five along the tunnel and one in the climatic chamber) consisting of a hygrometer and a humidity sensor to check the measurements obtained. The hygrometers consist of two temperature sensors (wet and dry bulb).

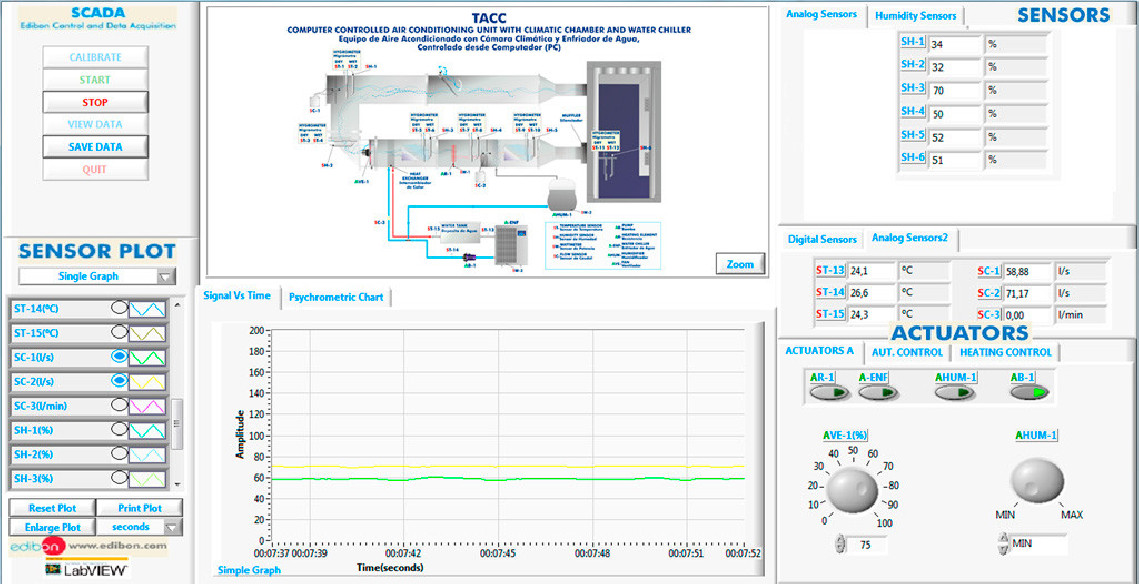

The software of the unit allows a manual operation of the system, controlling each stage and setting stable conditions for research, or an automatic operation, setting comfort conditions in the climatic chamber.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Understanding and operation of the main components and stages of an air conditioning system: cooling, heating, humidification and drying.

- Understanding and use of the psychrometric chart of the air from measurements with dry bulb and wet bulb.

- Study and understanding of the influence of the cooling/drying stage in the air conditioning process.

- Study and understanding of the influence of the heating stage in the air conditioning process.

- Study and understanding of the influence of the humidifying/dehumidifying stage in the air conditioning process.

- Operation of the system elements and representation of the air conditioning complete cycle on a psychrometric chart.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Energy balance in the heat exchanger and study of the losses.

- Energy balance during the heating process.

- Energy balance in the cooling unit.

- Mass balance in complete system, assessment of air losses.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TACC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TACC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

Оборудование для кондиционирования воздуха (рециркуляция), управляемое компьютером (ПК)

Лабораторное оборудование для кондиционирования воздуха

Оборудование для рециркуляции воздуха кондиционирования

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Учебное оборудование для производства горячей воды и отопления, управляемое компьютером (ПК)

Оборудование для переработки биомассы, управляемое компьютером (ПК)

Оборудование для переработки биомассы

Оборудование для изучения эффективности системы отопления, управляемое компьютером (ПК)

Учебное оборудование для водонагревателей

Тепловой насос для различных источников и теплообменников

Теплый пол и/или источник тепла для теплового насоса

Обогрев Воздуха и/или Теплообменник Воздуха

Лабораторное оборудование для кондиционирования воздуха, управляемое компьютером (ПК)

Лабораторное оборудование для кондиционирования воздуха

Оборудование для кондиционирования воздуха (рециркуляция), управляемое компьютером (ПК)

Оборудование для рециркуляции воздуха кондиционирования

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie