TGFAC Турбина газовая осевого потока/ Реактивный двигатель, управляемые с компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

The Computer Controlled Axial Flow Gas Turbine/ Jet Engine, "TGFAC", designed by EDIBON is a teaching unit that demonstrates the operation of a gas turbine as reaction engine.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

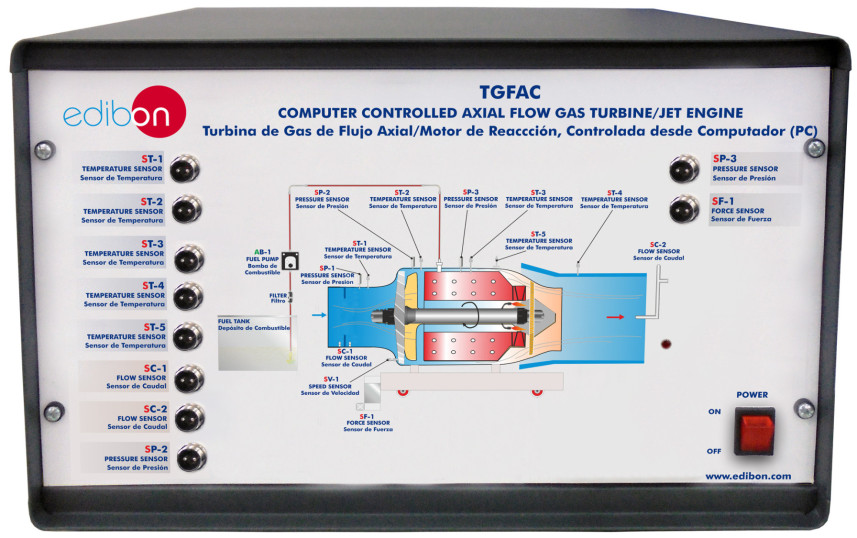

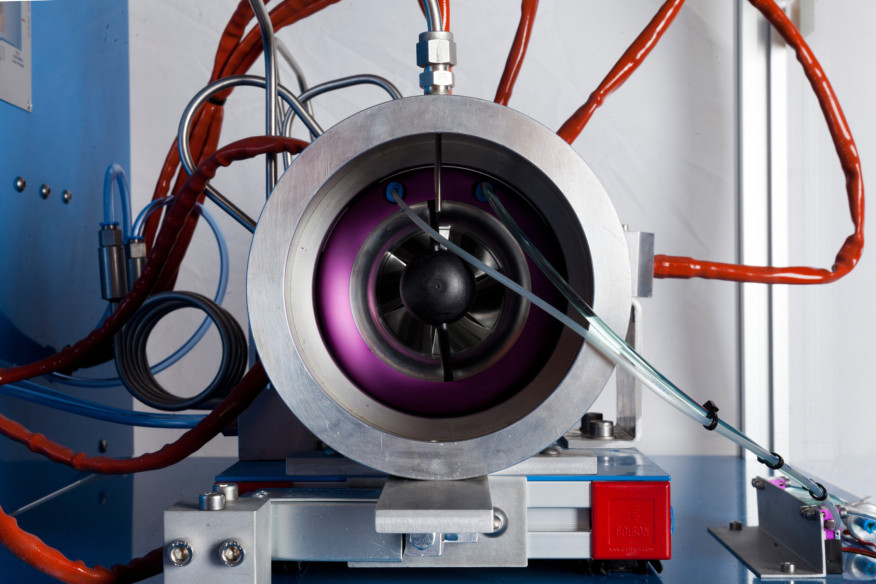

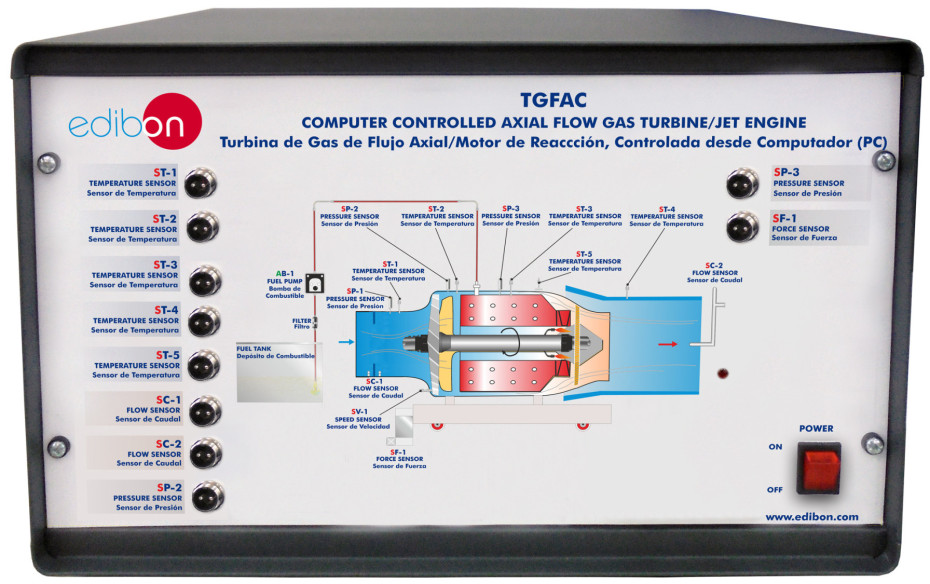

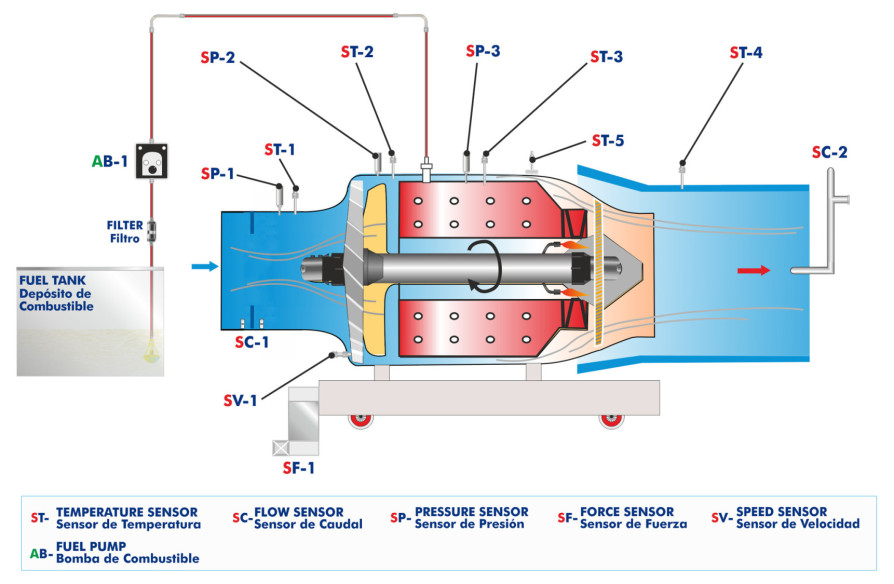

The main element of the "TGFAC" unit is the gas turbine, which consists of:

- Axial compressor, supplied by atmospheric air that will be compressed afterwards.

- Annular combustion chamber, where fuel is added to the compressed air and that mixture is burnt. The combustion gases increase their temperature and velocity.

- Expansion axial turbine. The obtained combustion gases flow to the axial turbine, where they transfer part of their energy to the vanes. Since the compressor and the turbine are coupled on the same shaft, when the system is self-sustained, part of the energy of the combustion gases is used to move the compressor. Both the turbine and the compressor are made up of discs with vanes that rotate (rotor) and stationary ones (stator). The difference is that the compressor transforms kinetic energy into pressure while the turbine performs the opposite work. The gas expands when being expelled, its temperature drops and is accelerated. It is expanded till environmental pressure at the outlet of the nozzle and reaches great speed, generating the thrust.

The gas turbine works as open cycle process, air is taken from the environment and expelled to the environment.

Besides, the unit includes a series of additional installations:

- Starting system: it is completely automatic, it is done with the aid of an electric starter motor that, coupled to the shaft of the compressor, generates the rotation of the shaft. There is a spark plug for the ignition.

- Fuel supply system: the fuel (kerosene/paraffin) passes through a filter and is supplied by a pump to the combustion chamber.

- Lubrication of the turbine: it is carried out with the oil mixed with the fuel (with a proportion of 5 % of special turbine oil).

The "TGFAC" unit includes the sensors required to measure all the important parameters of the process: pressure, temperature, air flow and fuel flow, speed and force (movable table with force sensor to measure thrust).

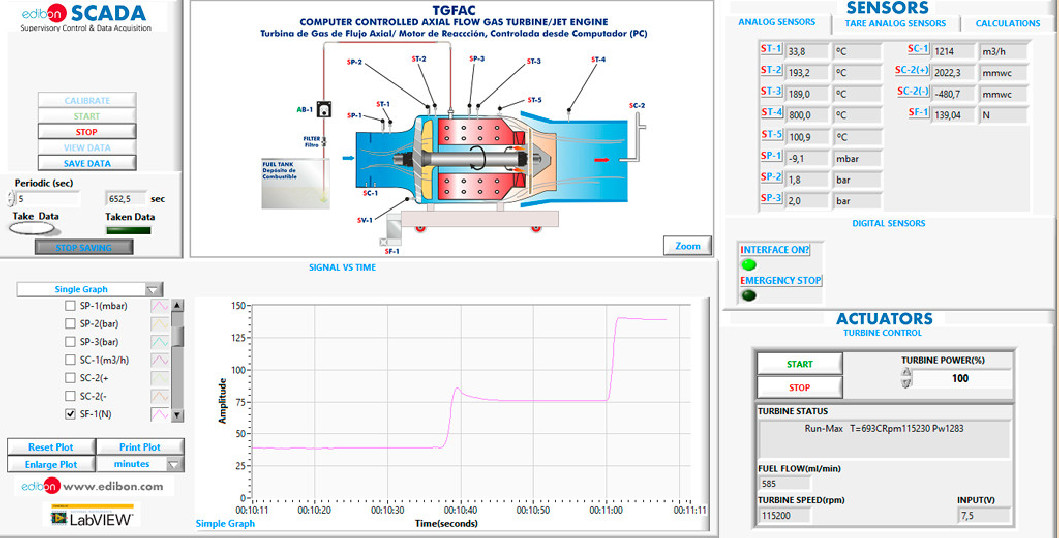

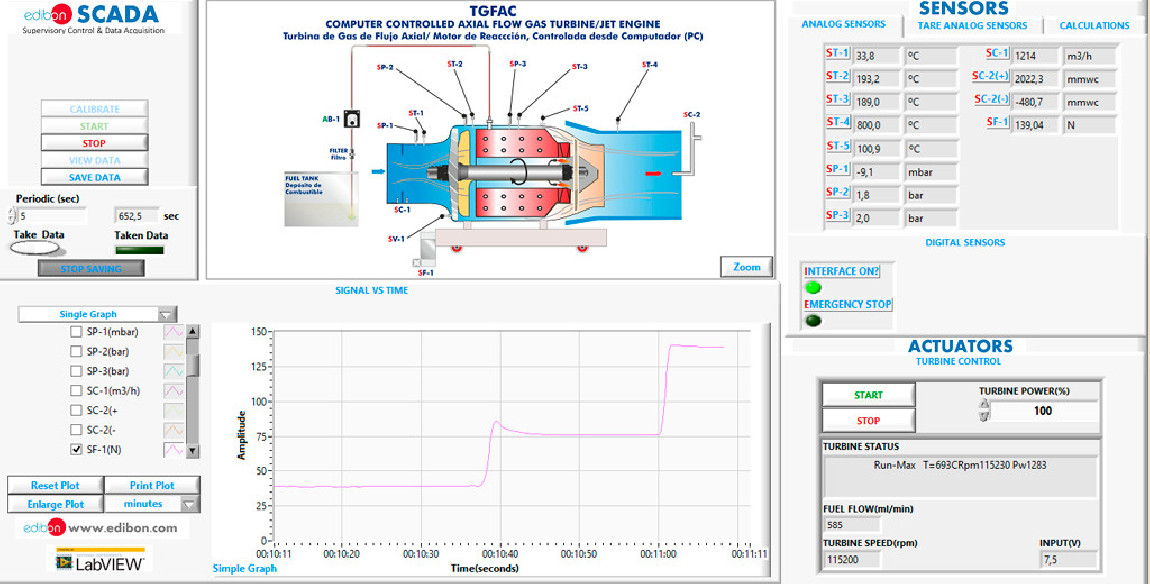

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Study of a gas turbine.

- Function and operation of a gas turbine as jet engine.

- Determination of fuel consumption.

- Determination of air and fuel ratio.

- Recording the relevant parameters of the turbine.

- Determination of the efficiency of the compressor.

- Determination of the turbine thrust.

- Determination of the efficiency of the gas turbine.

- Determination of the gas turbine characteristic curves.

- Determination of the compression ratio of the compressor at different thrust regimes.

- Determination of the gas turbine specific consumption.

- Study of the safety systems in the operation of a gas turbine.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TGFAC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TGFAC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Испытательный Стенд для Двигателей 7,5 кВт, Управляемый компьютером (ПК)

Испытательный Стенд для Двигателей 11 кВт, Управляемый компьютером (ПК)

Испытательный стенд с компьютерным управлением для 75 кВт

Банка для испытаний и диагностики бензиновых двигателей с имитацией неисправностей

Банка для испытаний и диагностики дизельных двигателей внутреннего сгорания

Испытательный и диагностический стенд для гибридного двигателя с ПО для торможения и диагностики

Калориметр выхлопных газов, управляемый компьютером (ПК)

Анализатор выхлопных газов

Портативный анализатор летучих газов

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie