EDLC Обучающее устройство для розлива воды в пластиковую тару, управляемое с ПК

ИННОВАЦИОННЫЕ СИСТЕМЫ

The Computer Controlled Liquid Packaging Teaching Unit, "EDLC", unit is a liquid and semi-dense products dosing machine based on dose delivery through a pneumatically-operated cylinder.

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Liquid Packaging Teaching Unit, "EDLC", unit is a liquid and semi-dense products dosing machine based on dose delivery through a pneumatically-operated cylinder.

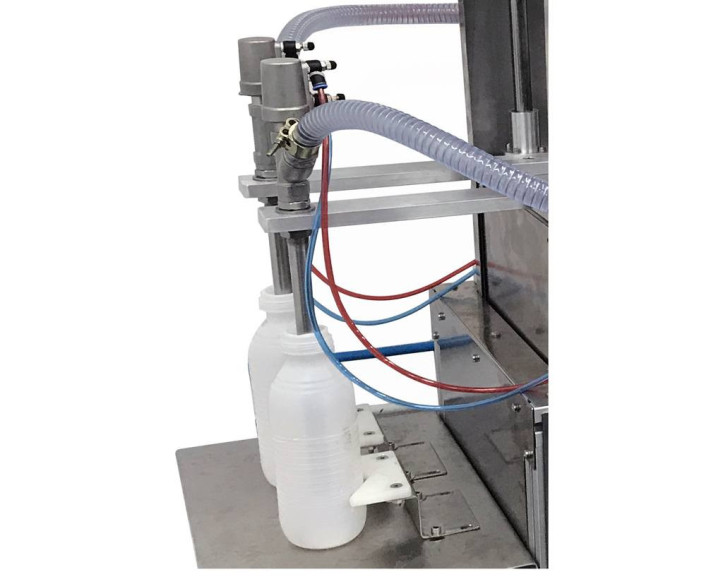

The product is absorbed by the unit from the tank installed for the user to have the product stored.

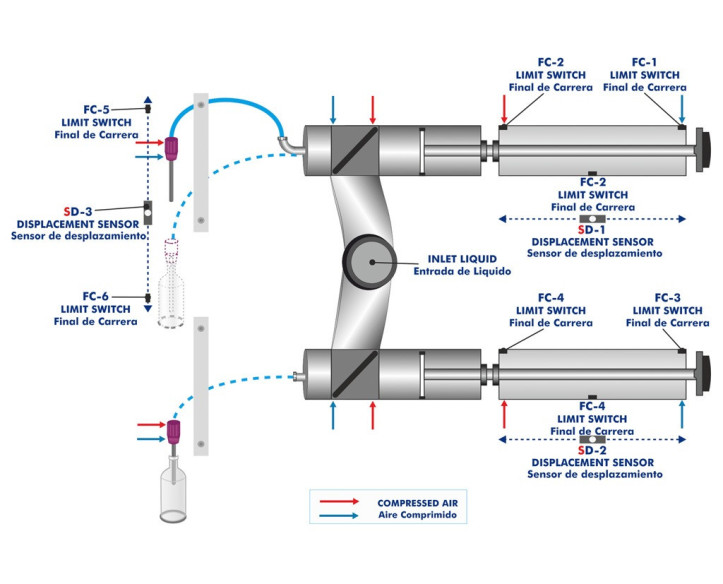

Afterwards, every time it is activated (manually with the pedal or the software), the unit delivers two doses through the two dosing nozzles. The dose delivered will be that one previously selected in the piston with a handle.

An automatic working mode can also be selected. In that case, the machine delivers doses on a repeated and continuous basis.

The unit also has a cleaning mode. It activates a dosing cycle that empties all the content of the dosing cylinder. It facilitates the cleaning inside the machine.

The unit can regulate these parameters:

- Lowering/lifting time of the dosing nozzles, making the dosage progressively made from the bottom of the bottle upwards by means of pneumatic flow regulators.

- Dose delivered by the unit by means of the manual handle.

- Closing/opening speed of the dosing nozzle.

- Dosing/suction speed by means of pneumatic flow regulators.

The hoses used in the dosing machine are coupled by quick release elements, so that when the coupling is disconnected, the air output is automatically interrupted and the disconnected part is slowly depressurized.

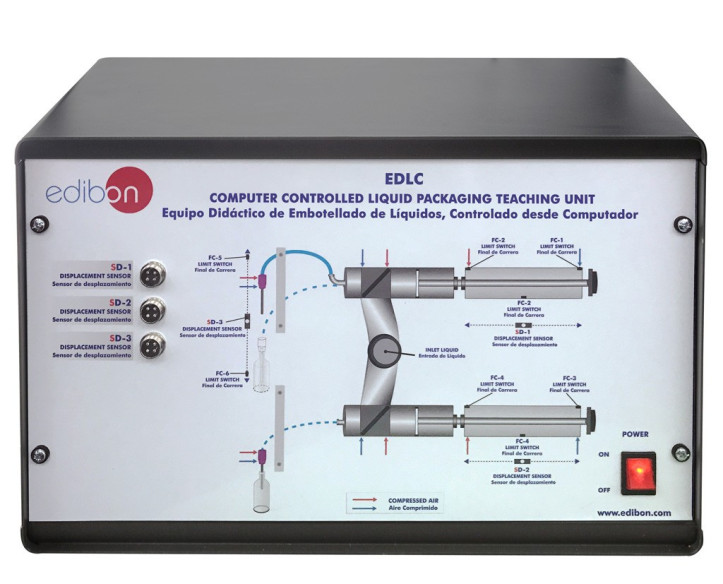

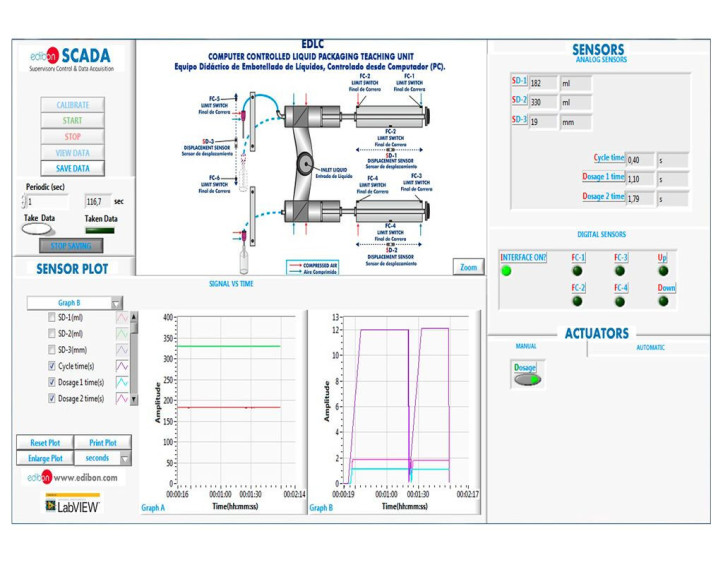

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Familiarization with the operation of a liquid filling machine.

- Study of the influence of the product level regulation on the bottles.

- Study of the influence of the type of liquid on the bottle filling.

- Study of the liquid dosing during the filling process.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EDLC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EDLC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Обучающий Сепаратор для Получения Сливок

Учебное оборудование для производства масла, управляемое компьютером (ПК)

Учебное оборудование для производства масла

Оборудование UHT, Управляемое с Компьютера (ПК) и Сенсорный Экран

Учебный автономный пастеризатор, управляемый с компьютером (ПК)

Управляемая ПК лаборатория пастеризации

Учебный Коагуляционный Бак, Управляемый компьютером (ПК)

Обучающий вертикальный пресс для сыроварения, управляемый с ПК

Голландская ванна для изготовления сыра (до 50 л)

Учебный инкубатор для йогурта, управляемый с компьютера (ПК)

Учебный оборудование для изготовления рикотты, управляемый с компьютера (ПК)

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie