PBRC Стенд поршневого насоса, управляемый с ПК

ИННОВАЦИОННЫЕ СИСТЕМЫ

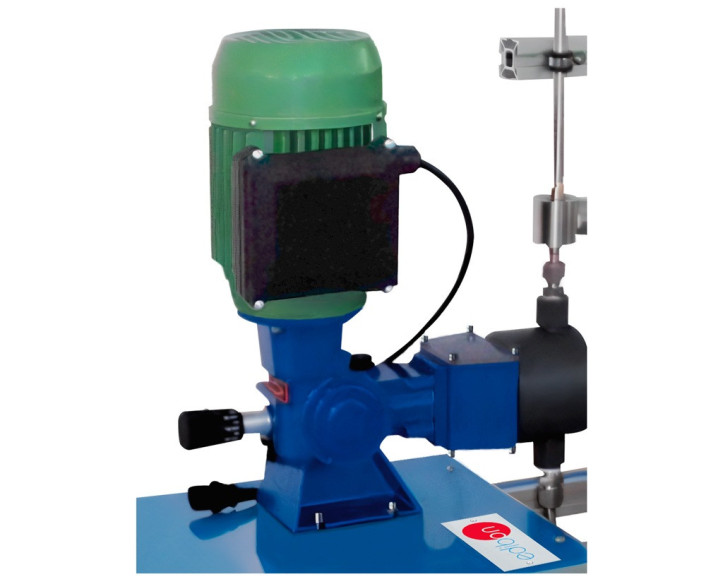

The Computer Controlled Piston Pump Bench, "PBRC", has been designed by EDIBON to obtain the most important characteristics curves and parameters of a piston pump.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

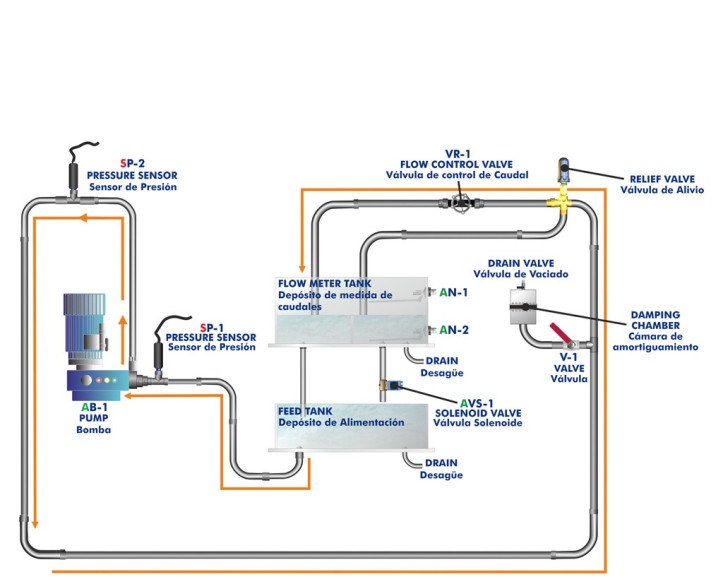

The Computer Controlled Piston Pump Bench, "PBRC", is a bench-top unit that consists of a piston pump, a feed tank, flow meter tank calibrated for taking flow measurements, circulation pipes, manual valves and a solenoid valve, computer controlled, as well as the enough control elements for the pump experiments: two pressure sensors and two level switches.

A frequency inverter for the pump, computer controlled, provides the possibility of regulation and measuring the pump motor speed, as well as the measurement of the torque transferred. The pump is installed in a pipes system which avoids the permanent water spending during the operation because it is a closed circuit.

The Computer Controlled Piston Pump Bench, "PBRC", unit has instrumentation and sensors to allow the measurement, from the computer, of most representative parameters of the piston pump:

- Admission and discharge pressure.

- Torque.

- Motor speed.

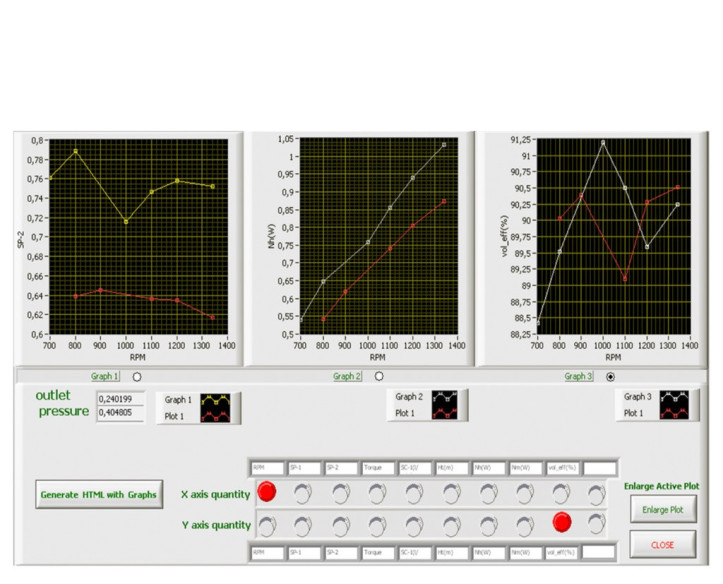

The software allows to calculate, with the measurement of the parameters:

- Total flow driven.

- Height of the pump.

- Hydraulic and mechanic power.

- Volumetric efficiency.

The unit includes the typical items a piston pump should have, such as: relief valve and damping chamber.

So one of the most important objetives of this unit is to study the influence that the presence of the damping chamber has.

The flow meter tank has a drain with a solenoid valve, computer controlled, to facilitate the discharge of the water into the feed tank, in case the water level in the flow meter tank is too high.

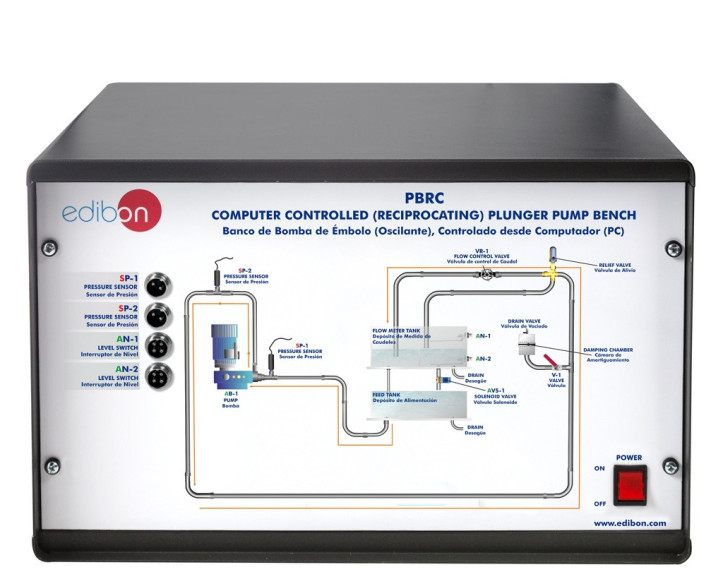

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Demonstration of a piston pump in operation.

- Measurement of plunger displacement of the piston pump.

- Measurement of piston pump inlet pressure.

- Measurement of piston pump outlet pressure.

- Measurement of the volumetric efficiency.

- Obtain the curves of a piston pump H(n), N(n).

- Obtain the piston pump map.

- Piston pump efficiency calculation.

- Study of the pressures influence at the outlet.

- Study of safety valve for overpressure in operation.

- Study of the pressures influence at the exit when the piston pump works with a damping chamber.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Sensors calibration.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the PBRC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the PBRC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Многонасосная тестовая платформа (для двух типов насосов), управляемая с ПК

Испытательная стойка для насосов в серии/параллель, управляемая с компьютера (ПК)

Последовательно/паралельные насосные стенды

Стенд шестерённого насоса, управляемый с ПК

Стенд аксиального насоса, управляемый с ПК

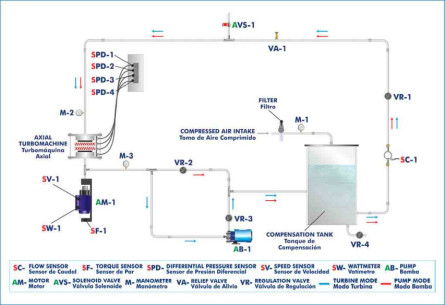

Оборудование для изучения осевых турбомашин, управляемое компьютером (ПК)

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie