TBMC3 Испытательный Стенд для Двигателей 2,2 кВт, Управляемый компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

The Computer Controlled Test Bench for 2.2 kW Engines, "TBMC3", designed by EDIBON, is a teaching unit to test internal combustion engines of up to 2.2 kW.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Test Bench for Single-Cylinder Engines, 2.2 kW, "TBMC3", designed by EDIBON, is a teaching unit to test internal combustion engines of up to 2.2 kW.

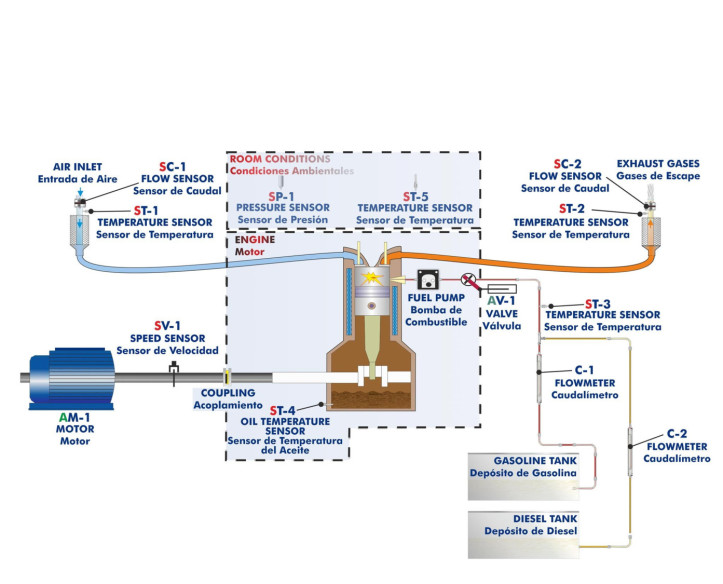

The unit has an element to exert the braking torque, an asynchronous motor fed by a variable frequency drive. The shaft of the motor is connected to the shaft of the engine by means of an elastic coupling.

The unit also includes:

- Instrumentation: there are several sensors that provide us measurements of the variables under study. Start system: the engine includes its own electric starter motor that facilitates its operation.

- Fuel supply system: it carries the required fuel to the internal combustion engine.

- Cooling system: The refrigeration is obtained by the passing of ambient air through the fins of the engine.

- Air intake system: it allows the intake of fresh air in the engine. It contains the oxygen required to generate the combustion.

- System to remove the exhaust gases: it removes from the engine the substances generated during the combustion and reduces the noise inherent to the gases flow.

The Computer Controlled Test Bench for 2.2 kW Engines, "TBMC3", allows to study combustion engines, obtaining their characteristic curves by setting the accelerator of the engine to a specific position and varying the braking torque. Thus, different points of the torque or power versus velocity characteristic curve are obtained. Such curve will be at full load if the accelerator is at its maximum position.

To ensure the optimal performance of the Computer Controlled Test Bench for 2.2 kW Engines, "TBMC3", it is essential to carefully select a specific engine that will be integrated into the test bench. This will allow us to conduct a series of experiments with a real engine in a completely safe environment, enabling us to collect accurate data on its various parts and functions.

Below are various engine options available for selection, of which at least one is required to work with the Computer Controlled Test Bench for 2.2 kW Engines, "TBMC3":

- TM3-01. Air-Cooled 4-Stroke 1-Cylinder Gasoline Engine for TBMC3. These engines are widely used in a broad range of applications, both in industrial environments and in small vehicles, such as lawnmowers, motorcycles, and portable generators. This type of engine is distinguished by its compact and simple design, which facilitates maintenance and repair. Being air-cooled, it eliminates the need for a liquid cooling system, making it lighter and less complex compared to liquid-cooled engines. This feature makes it especially useful in situations where weight and simplicity are critical, such as in portable applications or in unit with limited space. Additionally, its 4-stroke design provides more efficient combustion and smoother operation compared to 2-stroke engines, making it a popular choice for both industrial and consumer applications.

- TM3-02. Air-cooled 4-Stroke 1-Cylinder Diesel Engine for TBMC3. The Air-cooled 4-Stroke 1-Cylinder Diesel Engine, is commonly found in a wide variety of applications, from small industrial machinery to agricultural unit and portable generators. This type of engine is characterized by its robustness and reliability in demanding environments, where air cooling is preferred due to its simplicity and resistance to adverse conditions. Air cooling eliminates the need for a liquid cooling system, reducing the complexity of the engine and making it more suitable for applications where simplicity and portability are important. Additionally, these engines are known for their fuel efficiency and ability to operate in extreme temperature and humidity conditions.

- TM3-03. Air-cooled 4-Stroke 1-Cylinder Gasoline Engine (Variable Compression) for TBMC3. The Air-cooled 4-Stroke 1-Cylinder Gasoline Engine (Variable Compression) is found in a variety of applications, ranging from industrial unit to consumer devices. It is characterized by its ability to adjust the compression ratio based on operating conditions, allowing for greater efficiency in different load and speed situations. This type of engine is particularly useful in applications where high energy efficiency and flexible adaptation to variable work demands are required.

- TM3-04. Air-Cooled 2-Stroke 1-Cylinder Gasoline Engine for TBMC3. The "Air-Cooled 2-Stroke 1-Cylinder Gasoline Engine" is commonly found in a variety of applications, ranging from gardening unit and portable tools to small boats and motorcycles. It is characterized by its compact and lightweight design, making it ideal for applications where space and weight are critical. Additionally, being air-cooled, it does not require a liquid cooling system, simplifying its design and reducing its weight. This type of engine is known for its simplicity in construction and maintenance, as well as its power relative to its compact size.

- TM3-05. Air-Cooled 4-Stroke 1-Cylinder Gasoline and LPG Engine for TBMC3. The "Air-Cooled 4-Stroke 1-Cylinder Gasoline and LPG Engine" is commonly found in a variety of industrial and commercial applications. It is characterized by its versatility, as it can operate on both gasoline and liquefied petroleum gas (LPG), making it suitable for a wide range of uses. This type of engine is preferred in applications where a reliable and efficient power source is required, such as in portable generators, water pumps, and small construction machinery. Furthermore, being air-cooled, this engine has a simpler design and is less expensive to maintain compared to liquid-cooled engines, making it a popular choice in environments where simplicity and reliability are essential.

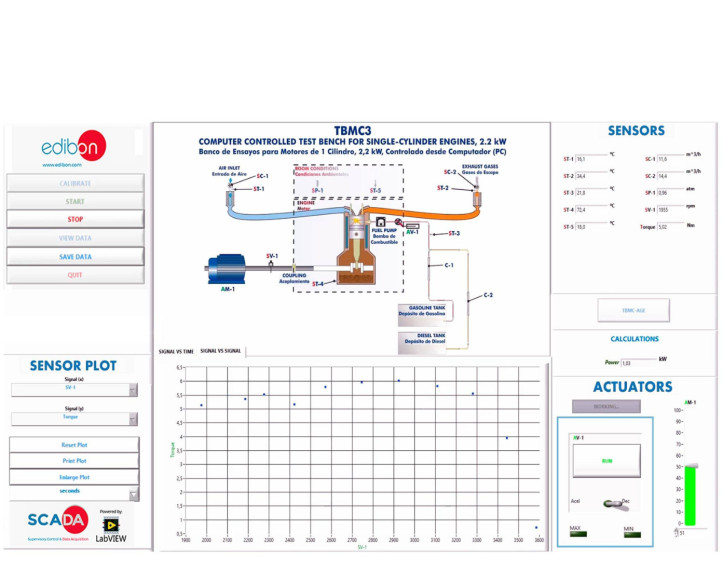

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Determination of the characteristic curves of an internal combustion engine at different speed regimes:

- Torque.

- Power.

- Specific consumption of fuel.

- Determination of the efficiency, fuel specific consumption and airfuel ratio of an internal combustion engine.

- Determination of the volumetric efficiency and the average effective pressure of an internal combustion engine.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Familiarization with four strokes petrol and diesel engines.

- Comparison of the characteristics of diesel oil and petrol engines.

- Study of cooling in alternative internal combustion engines.

- Analysis of an internal combustion engine exhaust gases (it requires the TBMC-AGE accessory). Recommended for petrol engines.

- Calculation of the heat contained in the exhaust gases of an internal combustion engine (it requires the TBMC-CG accessory).

- Sensors calibration.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the TBMC3 unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the TBMC3 unit process.

- Several other exercises can be done and designed by the user.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

Испытательный стенд с компьютерным управлением для 75 кВт

Испытательный Стенд для Двигателей 11 кВт, Управляемый компьютером (ПК)

Банка для испытаний и диагностики дизельных двигателей внутреннего сгорания

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Испытательный Стенд для Двигателей 7,5 кВт, Управляемый компьютером (ПК)

Испытательный Стенд для Двигателей 11 кВт, Управляемый компьютером (ПК)

Испытательный стенд с компьютерным управлением для 75 кВт

Банка для испытаний и диагностики бензиновых двигателей с имитацией неисправностей

Банка для испытаний и диагностики дизельных двигателей внутреннего сгорания

Испытательный и диагностический стенд для гибридного двигателя с ПО для торможения и диагностики

Калориметр выхлопных газов, управляемый компьютером (ПК)

Анализатор выхлопных газов

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie