EEEC Оборудование для изучения энергии ветра, управляемое компьютером (ПК)

ИННОВАЦИОННЫЕ СИСТЕМЫ

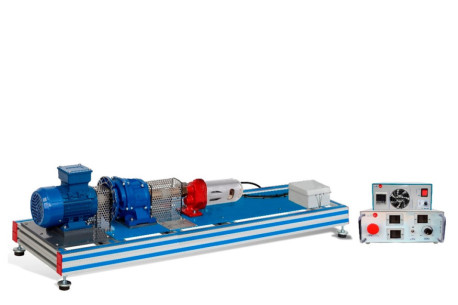

The Computer Controlled Wind Energy Unit, "EEEC", contains an aerogenerator, in laboratory-scale, and is used to study the conversion of kinetic wind energy into electrical energy and to study the influence of some factors on this generation.

Расширения

ЛАБОРАТОРИИ

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The Computer Controlled Wind Energy Unit, "EEEC", contains an aerogenerator, in laboratory-scale, and is used to study the conversion of kinetic wind energy into electrical energy and to study the influence of some factors on this generation.

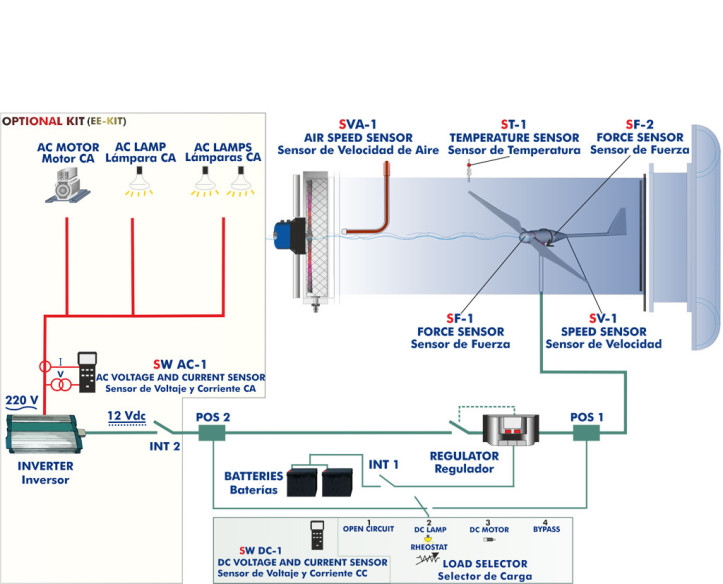

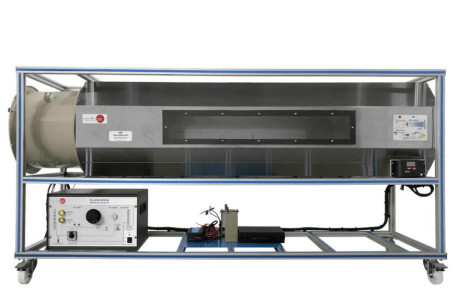

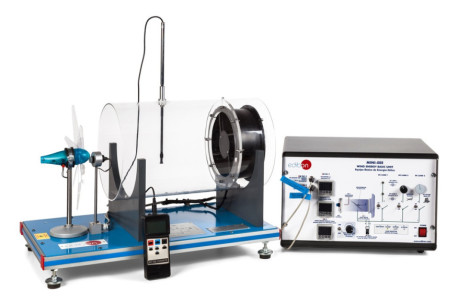

The unit consists of a stainless steel tunnel, an aerogenerator and an axial fan with variable speed (computer controlled). A rotor (or turbine) to place up to blades and a generator are the core elements of the aerogenerator.

The air speed is varied by changing the rotational speed of the axial fan. This fan generates the air flow required to set the rotor of the wind energy unit.

The generator converts the rotor's kinetic energy into electrical energy.

The aerogenerator incidence angle and the angle of every blade can be modified. The blades can be removable and it is possible to set different blade configurations.

This unit includes a DC Load Regulator, an auxiliary battery charger, a battery and a DC Loads module. The DC Loads module contains DC lamps, rheostat, DC motor, load selector and switches to select the type of load.

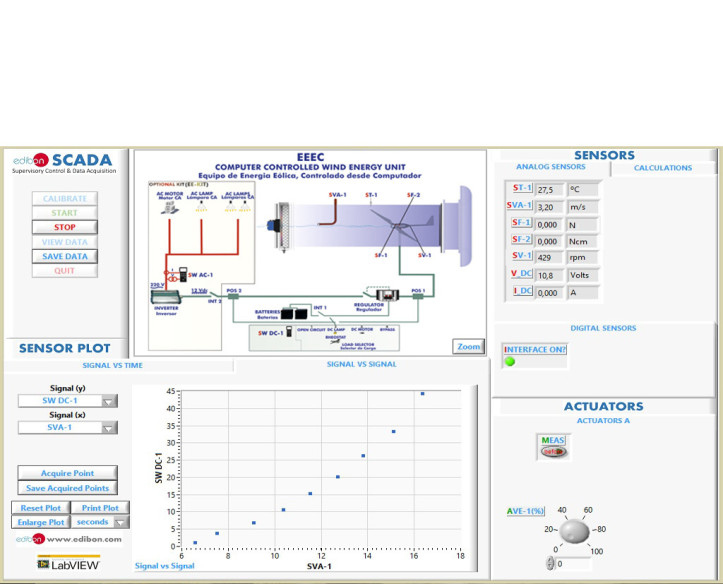

The following parameters are measured: air temperature, air speed, speed of the rotor, voltage and current. There is a temperature sensor before the rotor of the aerogenerator. The air speed is measured with a sensor placed in the tunnel and also is determined the rotational speed of the aerogenerator (r.p.m.). A voltage and current sensor allows to measure the voltage and current to determine the power.

It is possible to know, in real time, the value of the DC voltage and the current given by aerogenerator, measured before and after the regulator.

Besides, the Computer Controlled Wind Energy Unit, "EEEC", determines the thrust force on the wind turbine in direction of the wind and the mechanical torque of the wind turbine under operation.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the proces.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Identification and familiarization with all components of the unit and how they are associated with its operation.

- Familiarization with the regulator parameters and the wind energy measurements.

- Study of the conversion of kinetic wind energy into electrical energy.

- Study of the power generated by the aerogenerator depending on the wind speed.

- Determination of the typical parameters of the aerogenerator (short circuit current, open-circuit voltage, maximum power).

- Determination of the I-V curve.

- Study of voltage, current and power in function of different loads.

- Study of the influence of the load variation on the aerogenerator.

- Determination of the maximum power output of the aerogenerator.

- Determination of the P-air speed curve.

- Study of the power generated by the aerogenerator depending on the incident angle of the air.

- Study of the characteristic curve of the rotor.

- Study of the connection of loads to direct voltage.

- Sensors calibration.

БОЛЬШЕ ПРАКТИЧЕСКИХ УПРАЖНЕНИЙ ДЛЯ РАБОТЫ С УСТРОЙСТВОМ

- Study of the power coefficient.

- Study of the aerogenerator operation in function of the blade configurations (aerogenerator with six, three or two blades).

- Study of the optimum number of blades.

- Study of the aerogenerator operation in function of the angle of the blades.

- Study of the efficiency of a wind power unit.

- Determination of the efficiency of a wind power unit in function of the number of blades, angle of the blades and angle of the generator.

- Determination and study of the thrust force on the wind turbine.

- Determination and study of the mechanical torque of the wind turbine.

Practices to be done with the recommended element "EE-KIT":

- Study of the connection of loads to alternating voltage of 220 V.

Practices to be done with the recommended element "EE-KIT2":

- Study of the inverter connected to the grid simulator.

Other possibilities to be done with this Unit:

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivative parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the EEEC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the EEEC unit process.

- By using PLC-PI additional 19 more exercises can be done.

- Several other exercises can be done and designed by the user.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

Базовое оборудование для изучения энергии ветра, управляемое компьютером (ПК)

Базовое оборудование для изучения энергии ветра

Применение ветряных турбин в изолированных сетях

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Применение Ветряных Ферм с Двойно Питаемым Индукционным Генератором

Применение ветроэнергии с постоянными магнитами синхронного генератора

Применение ветроэнергии с постоянными магнитами синхронного генератора, с SCADA

Применение ветряных электростанций с индукционным генератором, управляемых с компьютера (ПК)

Применение ветрогенераторов с индукционным генератором

Применение ветряных турбин в изолированных сетях

Приложение для Насосов в Отдельных Сетях, Управляемое компьютером (ПК)

Приложение для насосных систем для изолированных сетей

Оборудование для изучения энергии ветра

Базовое оборудование для изучения энергии ветра, управляемое компьютером (ПК)

Базовое оборудование для изучения энергии ветра

Оборудование для Анализа Передачи Энергии Ветра

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie