Heat exchangers are widely used in refrigeration, air conditioning, heating, energy generation, chemical processing, etc. They have many applications in engineering and, as a consequence, there are many models adapted to each application to obtain an efficient heat transfer.

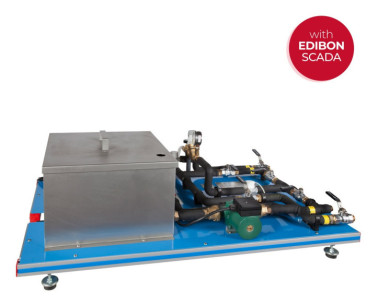

The Heat exchanger Training System, "TICB", has been designed by EDIBON to study and compare different types of small-scale heat exchangers working with parallel or counter flow arrangements.

The complete unit consists of two main elements: the base service unit and the required elements (at least one) (Not included).

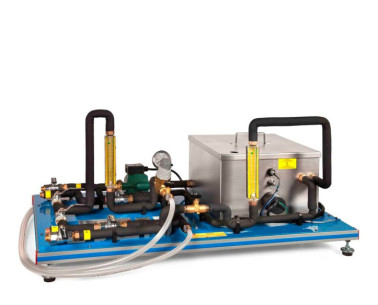

The Base Service Unit, "TIUSB", is common for the required elements (at least one) (Not included). Its functions are:

- Heating water in a thermostatic bath.

- Pumping the hot water.

- Regulation and measurement of the cold water and hot water flows.

- Measurement of the inlet and outlet temperatures of the cold water and the hot water.

- Measurement of the pressure drop in the exchanger.

Required elements (at least one) (Not included):

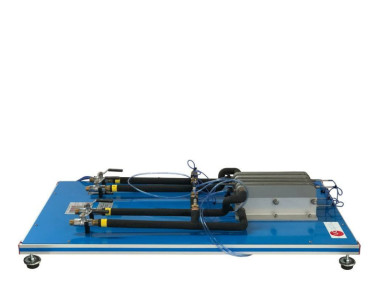

- TITCB. Concentric Tube Heat Exchanger for TICB: It has been designed to study the heat transfer between hot water flowing through an internal tube and cold water flowing through the annular area between the internal and the external tubes.

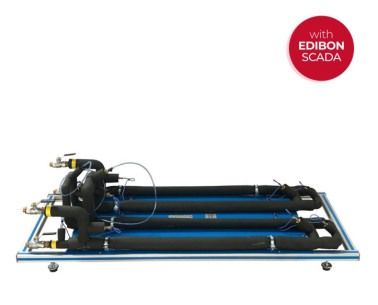

- TITCAB. Extended Concentric Tube Heat Exchanger for TICB: It has been designed to study the heat transfer between hot water flowing through an internal tube and cold water flowing through the annular area between the internal and the external tubes.

- TIPLB. Plate Heat Exchanger for TICB: It has been designed to study the heat transfer between hot water and cold water flowing through alternate channels formed between parallel plates.

- TIPLAB. Extended Plate Heat Exchanger for TICB: It has been designed to study the heat transfer between hot water and cold water flowing through alternate channels formed between parallel plates.

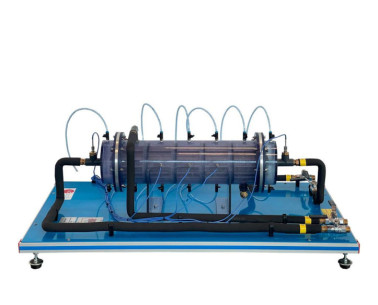

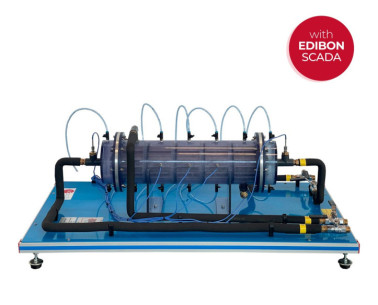

- TICTB. Shell and Tube Heat Exchanger for TICB: It consists of a series of tubes inside the heat exchanger where hot water flows. The cooling water flows through the space between the inner tubes and the shell.

- TIVEB. Jacketed Vessel Heat Exchanger for TICB: Allows the study of heat transfer between hot water flowing through a jacket and the cold water contained in a vessel.

- TIVSB. Coil Vessel Heat Exchanger for TICB: Allows the study of heat transfer between hot water flowing through a coil and cold watercontained in the vessel.

- TIFTB. Turbulent Flow Heat Exchanger for TICB: Let us study the heat transfer between hot water that circulates through an internal tube and cold water that flows through the annular zone between the internal and the external tube.

- TICFB. Cross Flow Heat Exchanger for TICB: Designed to study heat transfer between two fluids in cross flow configuration. Hot water flow coming from the base unit enters and leaves a radiator perpendicular to an air current, which is generated by a fan.

Настройки cookie

Настройки cookie