At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-T Учебная станция линейного транспорта

ИННОВАЦИОННЫЕ СИСТЕМЫ

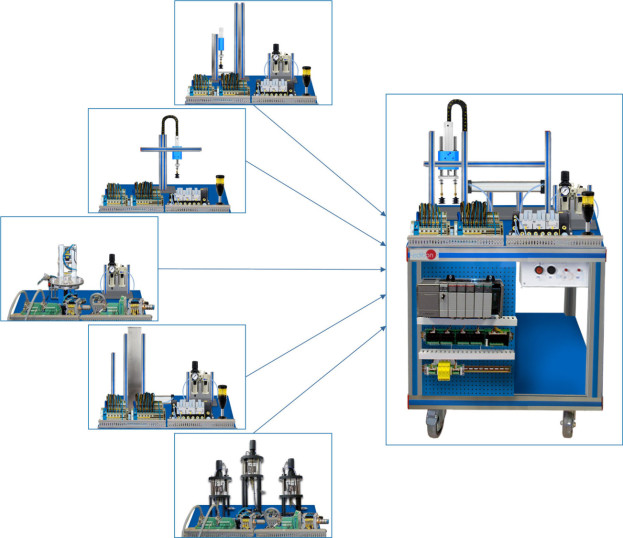

The "AE-PLC-T" is a linear transporting system, which moves the pallets, that carries the pieces, along the system.

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The "AE-PLC-T" is a linear transporting system, which moves the pallets, that carries the pieces, along the system. The unit is configured in a closed loop conveyor powered by an electrical motor, the whole system is commanded by a PLC.

The "AE-PLC-T" has different stopping places, where the system detects the pallet and is able to stop the transporting system.

The "AE-PLC-T" workstation is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by the CPU PLC unit and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The pneumatic circuit: contains the required solenoid valves, pressure components, pneumatic actuators, filters and regulators to assure the appropriate working of the unit.

- The workstation: is composed by real industrial components used by the industrial transporting systems, such as inductive sensors, presence sensors, motor controllers, etc.

The "AE-PLC-T" is an independent workstation that can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Introduction to flexible manufacturing system (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Study of the sensor detection.

- Configuration of a pneumatic application.

- Manual control of a transporting system.

- Automatic control of a transporting system.

- Change the parameters of a transporting process.

- Optimize the process time.

- Study and analysis of the faults inserted in the process with the fault generation module.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-MAE

The "AE-PLC-MAE" is an electrical handling system commanded by a PLC. The "AE-PLC-MAE" is composed of a two axis electrical manipulator with a pneumatic gripper to transport the pieces from the input pieces holder to the corresponding position,...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-MAN

Учебная пневматическая станция манипуляции

The "AE-PLC-MAN" is a pneumatic handling workstation commanded by a PLC, which performs handling and sorting functions.The workstation identify the color of the input pieces at the input pieces area, once the color is identified, the station take...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-MPS

Учебная станция манипуляции деталями

The "AE-PLC-MPS", Pieces Manipulator Workstation, is a unit that works with pneumatics, electro-pneumatics and vacuum technologies.The "AE-PLC-MPS" performs the following operation: moving a piece from one position to another by using suction pads...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-SPO

Учебная станция позиционирования

The Positioning Workstation, "AE-PLC-SPO", has been designed by EDIBON to studiy three-axis positioners for computer integrated manufacturing systems. It sorts incoming pieces based on material and dimensions using a PLC-controlled manipulator.The...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-CTCA

Учебная станция ленточного конвейера переменного тока

The "AE-PLC-CTCA" is an AC powered conveyor system commanded by a PLC. The "AE-PLC-CTCA" is composed by a conveyor, 4 position sensors to stop the conveyor at different positions, motor positioner, AC motor driver and three-phased motor to a...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-CTCC

Учебная станция ленточного конвейера постоянного тока

The DC Conveyor Belt Workstation, "AE-PLC-CTCC", explores DC conveyor system management, including piece classification. It features industrial components like PLC, sensors, etc., enabling control of an automatic DC-powered conveyor system with...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-MACT

Учебная пневматическая станция манипуляции и конвейерной ленты

The Pneumatic Handling and Conveyor Belt, "AE-PLC-MACT", is an automatic handling station with a conveyor system commanded by a PLC. The "AE-PLC-MACT" is composed of a pneumatic handling system that uses vacuum technology to move pieces from the...

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-MPS

Учебная станция манипуляции деталями

The "AE-PLC-MPS", Pieces Manipulator Workstation, is a unit that works with pneumatics, electro-pneumatics and vacuum technologies.The "AE-PLC-MPS" performs the following operation: moving a piece from one position to another by using suction pads...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-SPO

Учебная станция позиционирования

The Positioning Workstation, "AE-PLC-SPO", has been designed by EDIBON to studiy three-axis positioners for computer integrated manufacturing systems. It sorts incoming pieces based on material and dimensions using a PLC-controlled manipulator.The...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-MAE

Учебная электрическая станция манипуляции

The "AE-PLC-MAE" is an electrical handling system commanded by a PLC. The "AE-PLC-MAE" is composed of a two axis electrical manipulator with a pneumatic gripper to transport the pieces from the input pieces holder to the corresponding position,...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-MAN

Учебная пневматическая станция манипуляции

The "AE-PLC-MAN" is a pneumatic handling workstation commanded by a PLC, which performs handling and sorting functions.The workstation identify the color of the input pieces at the input pieces area, once the color is identified, the station take...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-CTCA

Учебная станция ленточного конвейера переменного тока

The "AE-PLC-CTCA" is an AC powered conveyor system commanded by a PLC. The "AE-PLC-CTCA" is composed by a conveyor, 4 position sensors to stop the conveyor at different positions, motor positioner, AC motor driver and three-phased motor to a...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-CTCC

Учебная станция ленточного конвейера постоянного тока

The DC Conveyor Belt Workstation, "AE-PLC-CTCC", explores DC conveyor system management, including piece classification. It features industrial components like PLC, sensors, etc., enabling control of an automatic DC-powered conveyor system with...

6.2.5.4.- РАБОЧЕЕ МЕСТО ДЛЯ УПРАВЛЕНИЯ ФРАГМЕНТАМИ ПРИЛОЖЕНИЙ

AE-PLC-MACT

Учебная пневматическая станция манипуляции и конвейерной ленты

The Pneumatic Handling and Conveyor Belt, "AE-PLC-MACT", is an automatic handling station with a conveyor system commanded by a PLC. The "AE-PLC-MACT" is composed of a pneumatic handling system that uses vacuum technology to move pieces from the...

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie