At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

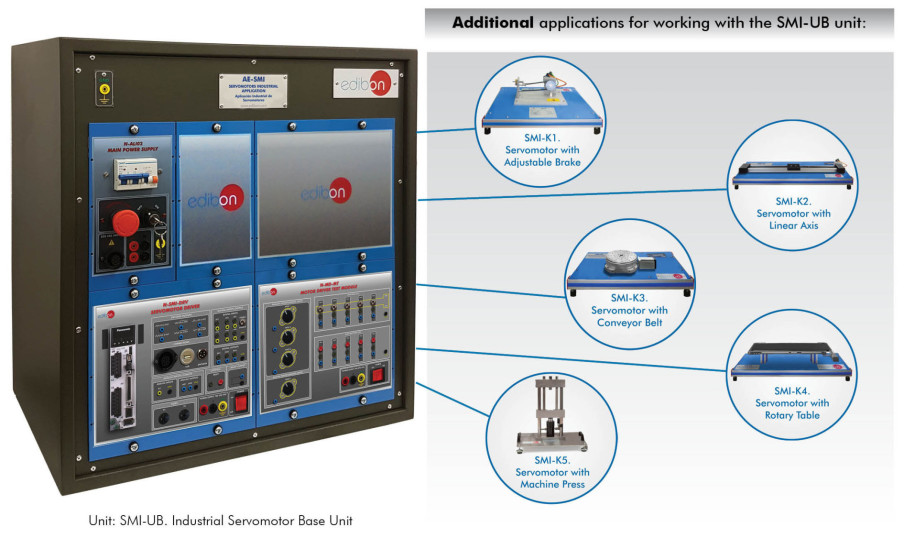

New unit has arrived! The Industrial Application of Servomotors (AE-SMI), has been designed to study the control system of a servomotor with a real application. It has a wide range of applications that contain real industrial systems, such as an automatic rotary table, a conveyor system or a...

On December 1st, the Repair Course for Small Laboratory Equipment, taught by our engineers at the EDIBON facilities, was completed, lasting 4 days.

The attendees, (Laboratory technicians and maintenance of the Rey Juan Carlos University of Madrid) had the opportunity to perform multiple...

Настройки cookie

Настройки cookie