At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-CF Учебная станция сортировки

ИННОВАЦИОННЫЕ СИСТЕМЫ

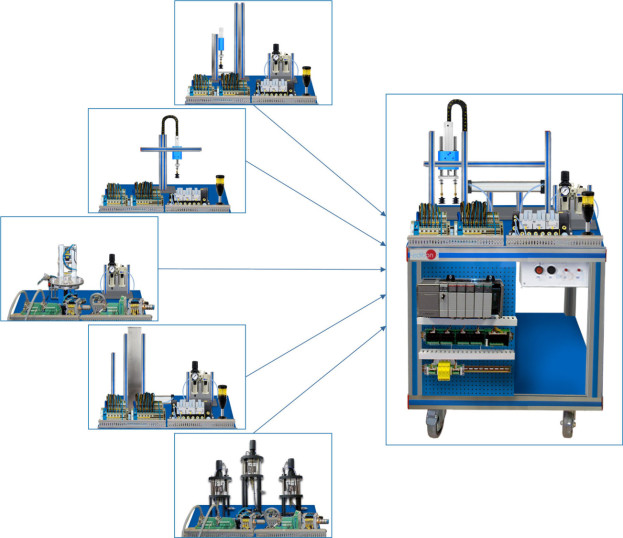

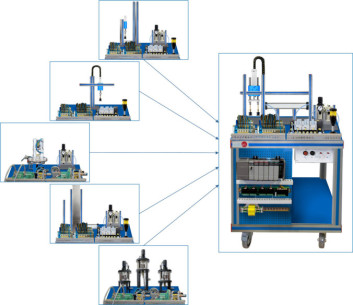

The "AE-PLC-CF" is a sorting workstation commanded by a PLC, which identifies the color and the type of the material of the input pieces and classifies them into three different places.

НОВОСТИ ПО ТЕМЕ

ОБЩЕЕ ОПИСАНИЕ

The "AE-PLC-CF" is a sorting workstation commanded by a PLC, which identifies the color and the type of the material of the input pieces and classifies them into three different places.

The "AE-PLC-CF" workstation is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by the CPU PLC unit and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The pneumatic circuit: it contains the required solenoid valves, filters and regulators to assure the correct working and safety of the unit.

- The workstation: it is composed by real industrial components used by the industrial sorting systems such as inductive sensors, reflective optical sensors, conveyor system, pneumatic actuators, etc.

The "AE-PLC-CF" is an independent workstation that can work alone and/or in conjunction with other workstations to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

УПРАЖНЕНИЯ И ПРИМЕРЫ С ИНСТРУКЦИЯМИ

РУКОВОДСТВО ПО ПРАКТИЧЕСКИМ УПРАЖНЕНИЯМ ВКЛЮЧЕНО В РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

- Introduction to flexible manufacturing system (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Study of the sensor detection.

- Configuration of a pneumatic application.

- Manual control of a sorting system.

- Automatic control of a sorting system.

- Change the parameters of the sorting process.

- Optimize the process time.

- Study and analysis of the faults inserted in the process with the fault generation module.

АНАЛОГИ ОБОРУДОВАНИЯ В НАЛИЧИИ

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-VS

The "AE-PLC-VS" is a quality control system commanded by a PLC. The "AE-PLC-VS" is equipped with a color camera that identifies the pieces on a conveyor belt. Depending on different specification, the system separates the corresponding pieces...

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-SLB

Учебная станция сортировки шариков

The Ball Selection Workstation, "AE-PLC-SLB", designed by EDIBON, allows the study of ball sorting mechanisms using PLC, pneumatic components, and industrial sensors. It facilitates the understanding of positioning, storage, and sorting processes....

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-RFID

Учебная станция идентификации с RFID

The "AE-PLC-RFID" is a workstation with RFID identification system. The workstation can write, read and rewrite information in the pieces using the RFID technology. The "AE-PLC-RFID" includes a conveyor system to transport the incoming piece to...

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-SIP

Учебная станция идентификации деталей

The "AE-PLC-SIP" is a quality control workstation commanded by a PLC, which check three characteristics of the input pieces. The workstation checks the color, the type of material and the height of input pieces.The "AE-PLC-SIP" workstation is...

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-CPD

Установка по отбраковке дефектных элементов

The "AE-PLC-CPD" is a Defective Pieces Sorter Workstation Application commanded by a PLC, which measures the deepness of the hole in the pieces. If the hole has not the correct deepness, the workstation sends the defective pieces to a rejection...

ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-SIP

Учебная станция идентификации деталей

The "AE-PLC-SIP" is a quality control workstation commanded by a PLC, which check three characteristics of the input pieces. The workstation checks the color, the type of material and the height of input pieces.The "AE-PLC-SIP" workstation is...

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-VS

Учебная станция контроля качества

The "AE-PLC-VS" is a quality control system commanded by a PLC. The "AE-PLC-VS" is equipped with a color camera that identifies the pieces on a conveyor belt. Depending on different specification, the system separates the corresponding pieces...

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-SLB

Учебная станция сортировки шариков

The Ball Selection Workstation, "AE-PLC-SLB", designed by EDIBON, allows the study of ball sorting mechanisms using PLC, pneumatic components, and industrial sensors. It facilitates the understanding of positioning, storage, and sorting processes....

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-RFID

Учебная станция идентификации с RFID

The "AE-PLC-RFID" is a workstation with RFID identification system. The workstation can write, read and rewrite information in the pieces using the RFID technology. The "AE-PLC-RFID" includes a conveyor system to transport the incoming piece to...

6.2.5.6.- РАБОЧЕЕ МЕСТО ДЛЯ ИДЕНТИФИКАЦИИ ФРАГМЕНТОВ ПРИЛОЖЕНИЙ

AE-PLC-CPD

Установка по отбраковке дефектных элементов

The "AE-PLC-CPD" is a Defective Pieces Sorter Workstation Application commanded by a PLC, which measures the deepness of the hole in the pieces. If the hole has not the correct deepness, the workstation sends the defective pieces to a rejection...

КАЧЕСТВО

ПОСЛЕПРОДАЖНОЕ ОБСЛУЖИВАНИЕ

Настройки cookie

Настройки cookie