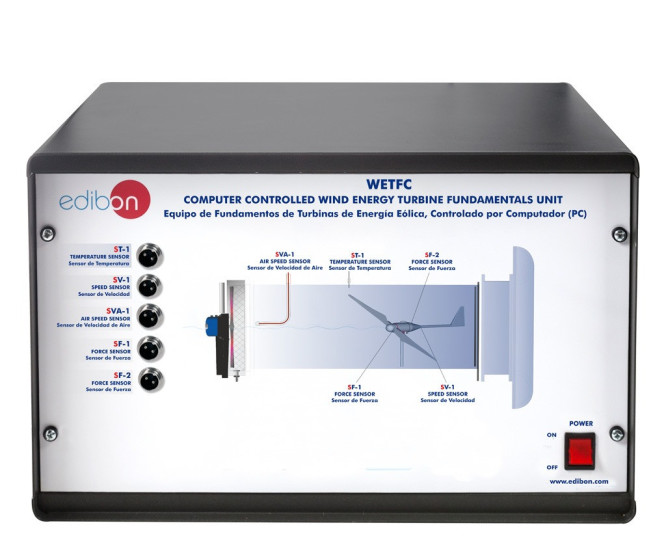

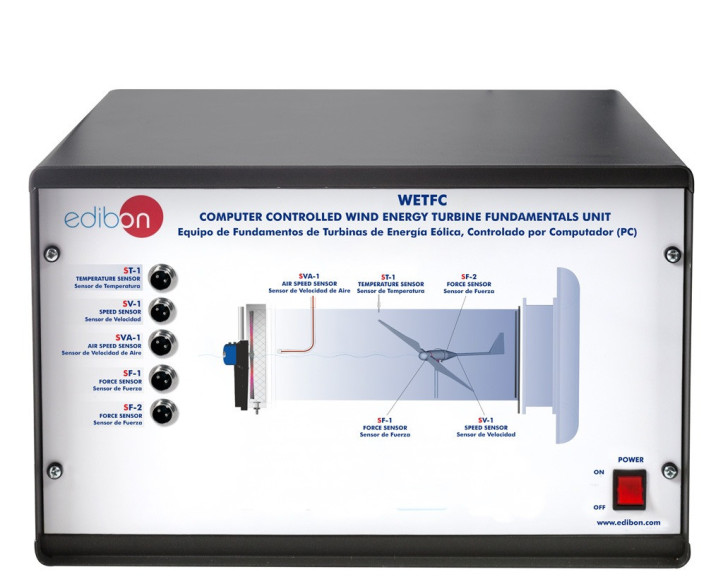

The Wind Energy Turbine Fundamentals Unit, "WETFC", is a small-scale and gearless unit designed to study wind energy power plants fundamentals and the influence of some factors on its generation, with adjustable rotor blades and a generator capable of operating at varying speeds.

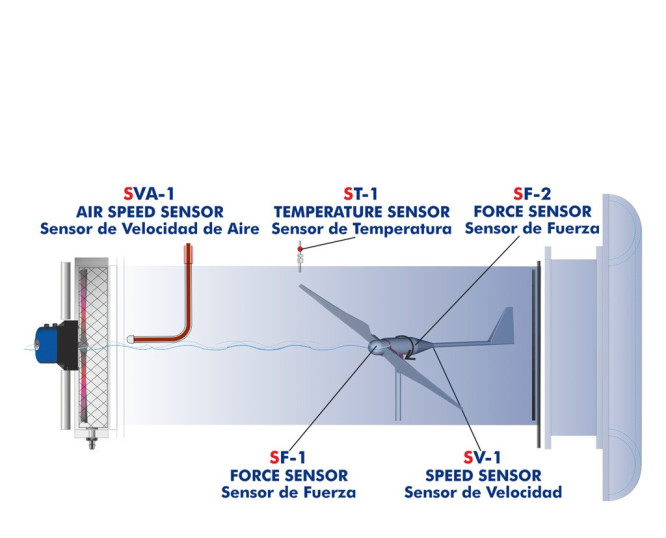

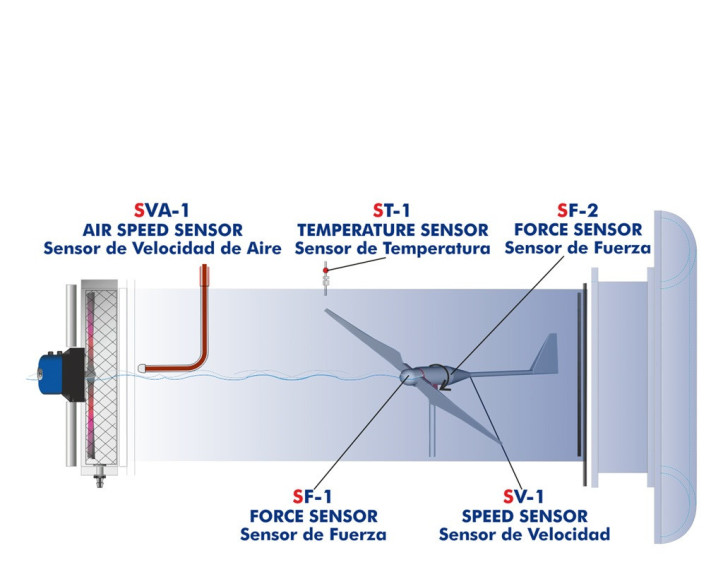

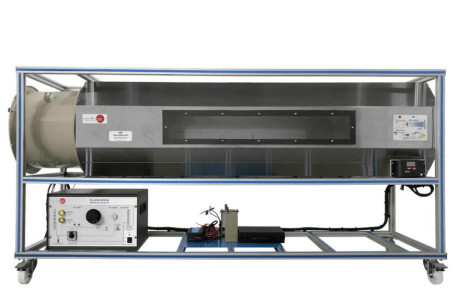

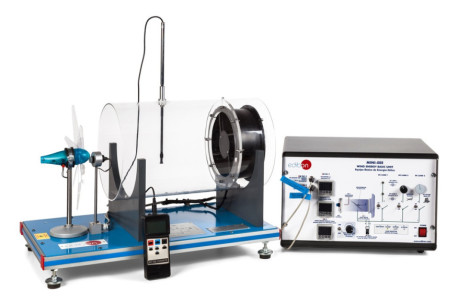

This unit comprises a tunnel, a wind turbine with adjustable rotor blades (up to three blades), and a variable speed axial fan, which allows power adjustment by modifying the wind speed. These components facilitate the study of various conditions and different speeds of a wind turbine.

The air speed is varied by changing the rotational speed of the axial fan, and a sensor allows for measuring that air velocity. A consistent and rectified flow ensures that the wind reaching the rotor is free of turbulence. This unit allows for uninterrupted operation and accurate study conditions. The rotor, located at one end of the system, directs the air directly towards the generator to facilitate research and analysis. The fan generates the necessary airflow to make the rotor of the wind energy unit work.

This unit allows for the study of the power coefficient (Cp), which is crucial for determining the efficiency with which a wind turbine converts wind energy into electrical energy. This efficiency is influenced by several factors, including the tip-speed ratio, the rotor blade adjustment angle, and the yaw angle. All these parameters are examined in this unit:

- Tip-Speed Ratio (TSR): The tip-speed ratio is defined as the ratio of the speed of the tips of the rotor blades to the wind speed. It is a critical factor in the design and operation of wind turbines. This unit enables the study of how different tip-speed ratios affect the turbine's performance.

- Rotor Blade Adjustment Angle: The angle of the rotor blades can be adjusted to control the amount of wind energy captured. This adjustment, known as pitch control, helps in optimizing the power output of the turbine. The unit allows experimentation with different blade angles to see how they impact efficiency and energy production, ensuring the turbine can respond to varying wind speeds and protect itself from damage in high winds.

- Yaw Angle: The yaw angle is the angle between the wind direction and the axis of the rotor. Adjusting the yaw angle ensures the turbine is optimally oriented towards the wind, maximizing energy capture. This unit facilitates the study of how adjusting the yaw angle affects the efficiency and performance of the wind turbine.

The generator converts the kinetic energy of the rotor into electrical energy. The rotational speed of the wind turbine can be measured with a sensor.

A current sensor measures the current provided by the wind turbine in order to determine the power.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Cookies首选项

Cookies首选项