AEHC Gerät zur Hydrierung, computergesteuert (PC)

INNOVATIVE SYSTEME

The Computer Controlled Hydrogenation Unit (PC), "AEHC", allows the study of the hydrogenation process in a discontinuous process, by adjusting the degree of saturation of edible oils.

Laboratorien

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The Computer Controlled Hydrogenation Unit (PC), "AEHC", unit is a batch processing vessel, which is used to adjust the degree ofsaturation of 22 l. batches of edible oils. It is easy and safe to use.

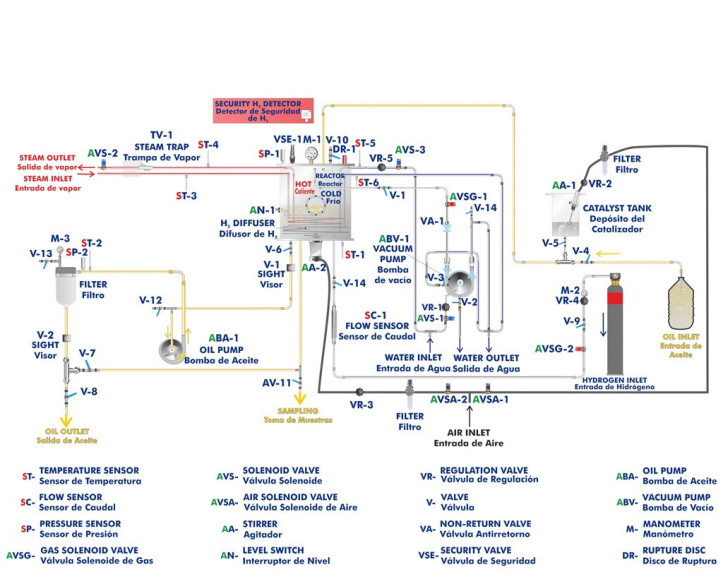

The Computer Controlled Hydrogenation Unit (PC), "AEHC", unit for oil hydrogenation has the following main elements:

- Catalyst tank where the catalyst is mixed with oil.

- Catalyst tank agitator to mix the catalyst and the oil.

- Hydrogenation vessel (reactor) where the three elements are mixed (oil, hydrogen and catalyst) and the reaction takes place.

- Reactor agitator to promote hydrogenation.

- Hydrogen diffuser for introducing hydrogen into the reactor.

- Heating coil through which steam at high temperature circulates in order to heat up the oil until the reaction starts.

- Cooling coil through which water circulates in order to limit the heating of the exothermic reaction.

- Vacuum pump for vacuum creation inside the reactor.

- Oil pump (filter pump) to extract oil from the reactor and take it to the filter.

- Filter where the hydrogenated oil is filtered to recover the catalyst.

- Visors, filters, regulators, ball valves, solenoid valves, non-return valve, security valve, rupture disc, hydrogen detector, manometers, temperature, pressure, level and flow sensors.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + aControl Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, forcontrolling the process and all parameters involved in the process.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Study of the effect of process temperature.

- Study of the effect of degree of agitation.

- Study of the effect of hydrogen gas pressure.

- Operation of small scale version of the industrial hydrogenation process.

- To determine the optimum catalyst dosage.

- To demonstrate the operation of the filter for catalyst recovery.

- Study of the effect of catalyst type.

- Sensors calibration.

MEHR PRAKTISCHE ÜBUNGEN FÜR DAS GERÄT

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains, proportional, integral, derivate parameters, etc, in real time.

- The Computer Control System with SCADA and PID Control allow a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical and electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

- Control of the AEHC unit process through the control interface box without the computer.

- Visualization of all the sensors values used in the AEHC unit process.

- Several other exercises can be done and designed by the user.

ERGÄNZENDE AUSRÜSTUNG

Sprühtrockner, computergesteuert (PC)

Sprühtrockner

Gerät für Sprühtrocknung und -kühlung, computergesteuert (PC)

Mehrzweckverarbeitungsbehälter, computergesteuert (PC)

Gerät für Umkehrosmose/Ultrafiltration, computergesteuert (PC)

Platten- und Rahmenfilterpresse, computergesteuert (PC)

Gerät zur Desodorierung, Computergesteuert (PC)

Fortschrittliches Gerät zur Desodorierung, Computergesteuert (PC)

Anlage zur kontinuierlichen Herstellung von Öl, computergesteuert (PC)

Didaktisches Gerät für die Abfüllung von Flüssigkeiten, computergesteuert (PC)

Didaktisches Gerät für die Verpackung von Feststoffen, computergesteuert (PC)

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen