At EDIBON, we are committed to strengthening skills as a strategic pillar for the competitiveness and social well-being of the European Union. Proper training not only boosts the economy but also enables individuals to fully participate in society and democracy.

AE-PLC-ALT Lernfabrik-Zwischenlagerstation

INNOVATIVE SYSTEME

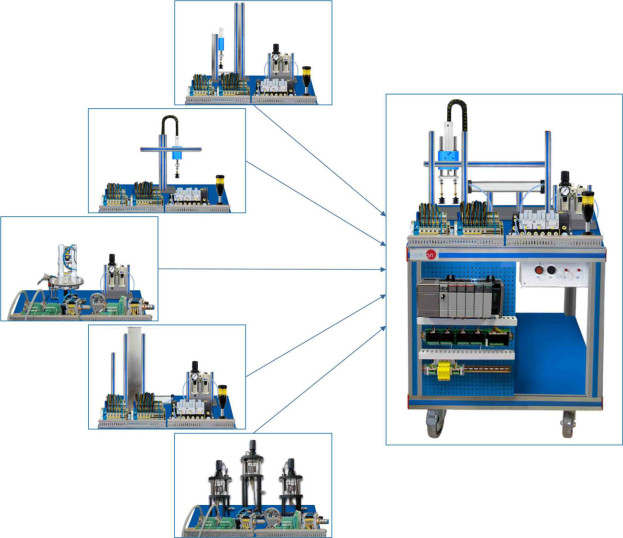

The "AE-PLC-ALT" is a Buffer Workstation commanded by a PLC that performs the functions of temporal storage of piece.

Erweiterungen

ÄHNLICHE NEUIGKEITEN

ALLGEMEINE BESCHREIBUNG

The "AE-PLC-ALT" is a Buffer Workstation commanded by a PLC that performs the functions of temporal storage of piece. The buffering function is used in many situations in the real industry for security or between different manufacturing stages.

The "AE-PLC-ALT" storage pieces temporarily, till the unit receive a signal that confirm that the next station required another piece.

The "AE-PLC-ALT" workstation is designed as a modular system to facilitate the understanding of the unit. The main components are:

- The PLC: is composed by an AE-PLCB (with HMI devices, analog and digital input/output, etc.) unit and all the extra modules needed to perform a correct working of the workstation.

- The control panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The pneumatic circuit: contains the required solenoid valves, the filters and regulators to assure the appropriate working of the unit.

- The workstation: is composed by real industrial components used by the industrial buffers systems such as reed sensors, a conveyor system with DC motor, IR beam detectors, etc.

The "AE-PLC-ALT" is an independent workstation that can work alone and/or in conjunction with other workstation to make up a complete Flexible Manufacturing system*.

*The Flexible manufacturing systems product list is available at "Flexible Manufacturing Systems (FMS)" area of the general catalogue.

ÜBUNGEN UND GEFÜHRTE PRAKTIKEN

GEFÜHRTE PRAKTISCHE ÜBUNGEN IM HANDBUCH ENTHALTEN

- Introduction to computer-integrated manufacturing (CIM).

- Introduction to pneumatics and electro-pneumatics.

- Study of the sensor detection.

- Configuration of a pneumatic application.

- Study an automatic buffer system.

- Change the parameters of the buffering process.

- Optimize the process time.

- Study the faults inserted in the process with the fault generation module.

ÄHNLICHE VERFÜGBARE GERÄTE

6.2.5.8.- LAGERUNG DER ARBEITSPLATZANWENDUNGEN

AE-PLC-AL

The "AE-PLC-AL" is an automatic Storage Workstation commanded by a PLC that moves the pieces at the desired position in a numbered grid.The "AE-PLC-AL" uses two electric linear actuators and a pneumatic manipulator to configure an automatic three...

6.2.5.8.- LAGERUNG DER ARBEITSPLATZANWENDUNGEN

AE-PLC-ALB

Lernfabrik-Dosenlagerstation

The "AE-PLC-ALB" is an automatic storage workstation for bottles with three degrees of freedom X-Y-Z. The "AE-PLC-ALB" is composed by two linear electrical actuators to move over the X-Y axes, and a pneumatic actuator (Z axis) with a vacuum cup...

6.2.5.8.- LAGERUNG DER ARBEITSPLATZANWENDUNGEN

AE-PLC-ALV

Lernfabrik-Vertikallagerstation

The Vertical Storage Workstation, "AE-PLC-ALV", studies the control of a vertical positioning, storage and sorting system. It enables understanding of controlling an automatic vertical three-axis storage system..It includes PLC, pneumatic...

ERGÄNZENDE AUSRÜSTUNG

6.2.5.8.- LAGERUNG DER ARBEITSPLATZANWENDUNGEN

AE-PLC-AL

Lernfabrik-Lagerstation

The "AE-PLC-AL" is an automatic Storage Workstation commanded by a PLC that moves the pieces at the desired position in a numbered grid.The "AE-PLC-AL" uses two electric linear actuators and a pneumatic manipulator to configure an automatic three...

6.2.5.8.- LAGERUNG DER ARBEITSPLATZANWENDUNGEN

AE-PLC-ALB

Lernfabrik-Dosenlagerstation

The "AE-PLC-ALB" is an automatic storage workstation for bottles with three degrees of freedom X-Y-Z. The "AE-PLC-ALB" is composed by two linear electrical actuators to move over the X-Y axes, and a pneumatic actuator (Z axis) with a vacuum cup...

6.2.5.8.- LAGERUNG DER ARBEITSPLATZANWENDUNGEN

AE-PLC-ALV

Lernfabrik-Vertikallagerstation

The Vertical Storage Workstation, "AE-PLC-ALV", studies the control of a vertical positioning, storage and sorting system. It enables understanding of controlling an automatic vertical three-axis storage system..It includes PLC, pneumatic...

QUALITÄT

KUNDENDIENST

Cookie-Präferenzen

Cookie-Präferenzen