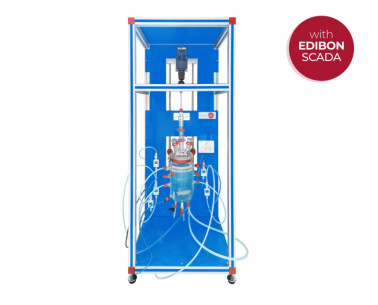

QRPC Computer Controlled Plug Flow Reactor for QRC

INNOVATIVE SYSTEMS

The Computer Controlled Plug Flow Reactor for QRC, "QRPC", designed by EDIBON, allows studying and investigating the kinetics of reactions and flow behavior in chemical systems. A plug flow reactor is a type of tubular reactor that assumes the assumption of no axial mixing of components along its length.

Expansions

Laboratories

RELATED NEWS

General Description

The Computer Controlled Plug Flow Reactor for QRC, "QRPC", designed by EDIBON, allows studying and investigating the kinetics of reactions and flow behavior in chemical systems. A plug flow reactor is a type of tubular reactor that assumes the assumption of no axial mixing of components along its length.

This type of reactor requires the application of a series of specific formulas over a volume differential instead of over the total volume, as is the case with perfectly mixed reactors.

This reactor enables the determination of key kinetic equations, such as the basic hydrolysis of ethyl acetate, which is fundamental for the design and optimization of industrial processes. It facilitates comparative analysis between theoretical and experimental conversion values, enhancing understanding of chemical processes.

Additionally, it examines the effect of flow rate and feed concentration on reaction efficiency and selectivity. Its ability to investigate the influence of temperature on laminar flow characterization is essential for optimizing chemical processes under variable conditions. Furthermore, it studies the reactor’s response to disturbances, such as pulses and step changes, providing vital information for the design and control of industrial chemical processes.

In summary, the piston flow reactor enables a wide range of practices and experiments, making it an invaluable tool for researchers, educators, and industry professionals seeking to understand and optimize complex chemical processes.

To work with this reactor, the Base and Service Unit, "QUSC", is required, which supplies the necessary reagents and thermostatic water for proper operation.

These Computer Controlled Units are supplied with EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

Exercises and guided practices

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Calibration of the reagents flows.

- Theoretical conversion of a plug flow reactor.

- Obtention of the concentration change of sodium hydroxide during the reaction and its conversion.

- Determination of the residence time distribution curve (RTD) in a plug reactor.

- Study the influence of the residence time in the conversion of the reaction.

- Determination of the order of reaction and the speed constant.

- Study of the reactor response to different perturbations at the reactor inlet: pulse and step change.

- Sensors calibration.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Determination of the residence time distribution of the reactor.

- Effect of flow rate and feed concentration on the determination of flow pattern.

- Effect of flow rate and feed concentration on the steady state conversion.

- Demonstration of the flow pattern in the reactor and comparison with the theoretical model.

- Determination of the steady state conversion of a second order reaction.

- Understanding the principles of tracer techniques in flow pattern characterisation.

- Conductivity measurement system: conductimeter.

Other possibilities to be done with this unit:

- Détermination de la distribution des temps de séjour dans le réacteur.

- Effet du débit et de la concentration de l'alimentation sur la détermination du schéma d'écoulement.

- Étude de la réponse du réacteur à différentes perturbations : changement par étapes et par impulsions.

- Effet du débit et de la concentration d'alimentation sur la conversion en régime permanent.

- Démonstration de la configuration de l'écoulement dans le réacteur et comparaison avec le modèle théorique.

- Détermination de la conversion en régime permanent d'une réaction du second ordre.

- Compréhension des principes des techniques de traçage dans la caractérisation de l'écoulement.

- Étude du système de mesure de conductivité : conductimètre.

- Calibrage des capteurs.

SUPPLEMENTARY EQUIPMENT

Base and Service Unit for QRQC

Isothermal Reactor with Stirrer

Isothermal Reactor with Stirrer and Distillation

Tubular Flow Reactor

Reactors with Stirrer in Series

Adiabatic and Isothermal Reactor

Computer Controlled Chemical Reactors

Base and Service Unit for QRC

Computer Controlled Continuous Stirred Tank Reactor for QRC

Computer Controlled Tubular Flow Reactor for QRC

Computer Controlled Batch Reactor for QRC

Quality

AFTER-SALES SERVICE

Cookie preferences

Cookie preferences