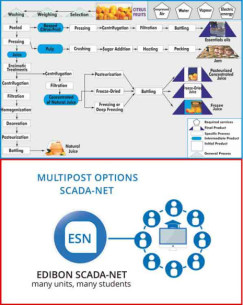

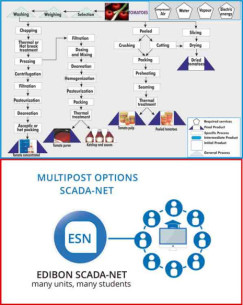

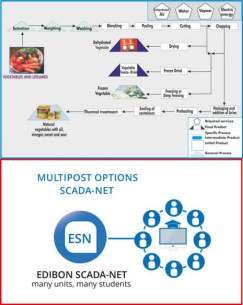

The Pilot Plant for Juice Production, "FR00/JP", is a pilot-scale facility that includes all the industrial stages for purees production.

In the production plant of fruit purees, the process begins with the reception of fresh fruit, where a meticulous process of selection, washing, and preparation of the fruit is carried out. To carry out these stages in the pilot plant, the following unit is included:

- WMFV. Washing Machine for Fruit and Vegetables. Fruit washing is essential to ensure hygiene and food safety. Its function is to remove any dirt, residue, or surface contaminants from the fresh fruit, ensuring that it is clean and ready for processing. In addition, during this process, pieces of fruit that do not meet the quality standards for consumption are discarded. Once the selection is complete, the fruit is peeled if necessary, preparing it for the next step: obtaining the fruit pulp.

- FPCR. Fruit Pitting and Crushing Unit. The fruit preparation process involves pitting and crushing the fruit to break down the cells and release the juice efficiently, which plays a key role in the fruit preparation stage. The unit crushes the fruit and removes the pits and seeds from the fruit, which facilitates juice extraction and ensures greater efficiency in the process.

The pilot plant is equipped with a homogenizing unit capable of mixing the previously obtained crushed fruit with the necessary seasonings and spices to achieve the desired quality and flavor:

- DMH/CTS. Computer Controlled and Touch Screen Milk Homogenizer. The homogenizer is essential to improve its flavor, texture, or preservation. In addition, the unit also allows the puree to be mixed with other ingredients or additives, which can improve the quality of the final product.

Once the puree is obtained, the product goes through a pasteurization process, where two alternative units are available: the Computer Controlled Teaching Autonomous Pasteurization Unit, "PADC" and the Computer Controlled and Touch Screen UHT Unit, "AUHT/CTS". In this way, the pilot plant includes just one pasteurization unit of the two mentioned previously, according to the needs of the process.

This step is essential to ensure the proper preservation of the product, extending its shelf life and maintaining its freshness and natural flavor. There are three different processes: VAT or slow pasteurization, High temperature short time pasteurization (HTST) and Ultra-High Temperature pasteurization (UHT).

- PADC. Computer Controlled Teaching Autonomous Pasteurization Unit. It allows to study VAT or slow pasteurization and its process variables. The unit receives puree from a refrigeration tank (not included) and this is impelled with a pump (computer controlled). It is heated in the heat exchanger, by counter-current flow, with hot water coming from a circuit formed by a water tank with a heating element (computer controlled), a water pump (computer controlled), a manometer, a security valve, an expansion vessel, a purge valve and a pressure regulator, until reaching the established pasteurization temperature.

- AUHT/CTS. Computer Controlled and Touch Screen UHT Unit. It is a compact design and easy installation pilot plant that works as an independent unit or as part of an integrated process finishing that allows for studying in depth the UHT (at Ultra-High Temperature) pasteurization process of products and the variables of the process.

Both pasteurizers are used to heat the puree to a temperature sufficient to eliminate harmful bacteria and microorganisms, without compromising the flavor and nutrients of the puree. This process helps to extend the shelf life of the product without significantly altering its properties.

To ensure food safety and the quality of the final product, it is crucial to sterilize the jars and equipment that will come into contact with the final product. The following unit is required for this purpose:

- BIEV. Computer Controlled Steam Sterilizer Unit. This unit effectively eliminates any harmful microorganisms present on packaging and production tools, also contamination is prevented, and the shelf life of the purees is prolonged. Steam sterilizer, consisting of an autoclave, is a real unit used in many medical and research centers for the proper sterilization of typical instruments, avoiding potential contamination effects from infectious pathogens. It carries out the sterilization process in a sealed chamber at high pressure and temperature through proprietary software that allows monitoring of the process at all times.

The product is bottled using a bottling and capping machine. The plant has two alternative bottling machines: the Computer Controlled Liquid Packaging Teaching Unit, "EDLC" and the Packaging Machine for Viscous Agri-food Products, "PVAFP". Therefore, the pilot plant includes one of the two bottling units mentioned above, as required:

- EDLC. Computer Controlled Liquid Packaging Teaching Unit. This unit allows the product to be stored in containers suitable for transport and preservation, ensuring that they reach the final consumer with maximum quality and freshness. The Computer Controlled Liquid Packaging Teaching Unit, "EDLC", is a liquid and semi-dense products dosing machine based on dose delivery through a pneumatically-operated cylinder. The packer is responsible for filling the containers with the processed product in an efficient and sanitary manner.

- PVAFP. Packaging Machine for Viscous Agri-food Products. This unit doses more viscous liquid products compared to the possibility of packaging liquid or semidense products from the "EDLC." Similarly, the bottling machine is responsible for efficiently and hygienically filling containers with processed purees, ensuring the transportation and proper storage of the product.

Finally, the product is capped and sealed for proper preservation in the next unit supplied:

- EDMT. Capping Machine for Agri-food Liquid Products. The capper is responsible for placing the hermetic caps on the purees-filled containers, ensuring that they are securely sealed and that the product is protected against contamination and oxidation. This unit together with the bottling machine ensures that the final product is ready for distribution and consumption, maintaining its freshness and quality.

Depending on the required production and the characteristics of the fruits to be treated there are recommended the following elements:

Additional recommended elements (Not included):

Once the fruit is prepared and crushed in the Washing Machine for Fruit and Vegetables, "WMFV" and the Fruit Pitting and Crushing Unit, "FPCR", it can be pressed. Fruit pressing is a process used to separate the juice from the pulp and seeds of fresh fruit. Depending on the requirements it can be useful to obtain a smoother puree free of unwanted chunks, which improves the texture and quality of the final product.

The Sheet Press for Liquid Products Extraction, "SPLE" and/or the Hydraulic Press for Liquid Product Extraction, "HPLE" (only one of the two units is recommended) can perform this function, depending on the type of pressing required.

- SPLE. Sheet Press for Liquid Products Extraction. The manual plate press is used to separate the juice from the pulp and the solids from the crushed fruit. Its manual operation allows a more precise control of the process and is ideal for smaller production batches.

- HPLE. Hydraulic Press for Liquid Product Extraction. Another form of pressing is the hydraulic press, which is a larger, automated version of the manual press. It provides uniform and controlled pressure on the crushed fruit, which facilitates efficient juice extraction and effective separation of solids.

Once the puree has been packaged, it is recommended to store it in the Computer Controlled and Touch Screen Refrigerator Reception Cabinet, "RRC/CTS" (not included), which allows preserving freshness, controlling temperature during processing, and preventing microbial growth, thus guaranteeing the quality and safety of the final product.

- RRC/CTS. Computer Controlled and Touch Screen Refrigerator Reception Cabinet. It ensures rapid cooling and helps maintain the desired texture and consistency of the puree, providing an optimal sensory experience for the end consumer.

If a high product flow is required, the use of a transit pump to pump and transport the intermediate products from the plant is recommended. The following unit can be considered for this application:

- TPAF. Transit Pump for Agri-food Products. This unit can be used with a wide variety of agri-food products and allows working in a wide range of flow rates.

Finally, during the whole production process, products and by-products are generated and can be stored in steel (not included) or polypropylene (not included) tanks suitable for working with agri-food products. The units that perform this function are:

- SSTAF. Stainless Steel Tank for Agri-food Products. Stainless steel tank designed for the storage of intermediate and final products in a plant. Its stainless steel construction ensures corrosion resistance and a hygienic surface. Its modular design and storage capacity make it ideal for efficient management of production processes.

- PTAF. Polyethylene Tank for Agri-food Products. Polypropylene tank designed for the storage of intermediate and final products in an industrial plant. Its polypropylene construction offers resistance to chemical corrosion and excellent durability, making it ideal for environments where agri-food substances are handled. Its lightweight and versatile design allows for easy installation and transport.

Cookie preferences

Cookie preferences