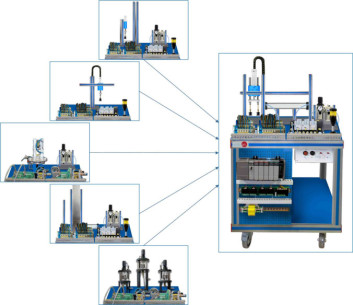

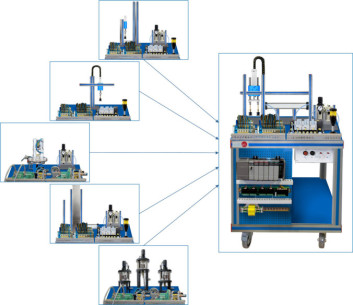

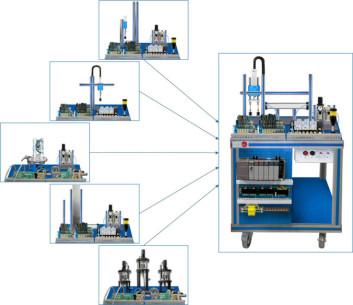

The Vertical Storage Workstation, "AE-PLC-ALV", studies the control of a vertical positioning, storage and sorting system. It enables understanding of controlling an automatic vertical three-axis storage system..It includes PLC, pneumatic components, and industrial sensors. It enables understanding of controlling an automatic vertical three-axis storage system.

The "AE-PLC-ALV" is an automatic storage workstation commanded by a PLC that checks material and dimensions of the incoming pieces to sort in a vertical storage.

The "AE-PLC-ALV" uses two electric and one pneumatic linear actuators to configure an automatic three axis vertical storage system. The "AE-PLC-AL" uses a double acting pneumatic gripper to handling the pieces from and to the vertical storage.

The "AE-PLC-ALV" workstation is designed as a modular system to facilitate the understanding.

The main components are:

- The PLC: is composed of the CPU PLC unit and all the extra modules needed to perform a correct working of the workstation.

- The Control Panel: with start/stop button, emergency pushbutton, reset button, light indicators to show current state of the process, etc.

- The Pneumatic Circuit: contains the required solenoid valves, the vacuum components, the filters and regulators to assure the appropriate working of the unit.

- The Workstation: is composed of real industrial vertical storage systems such as electric linear actuators, presence sensors, pneumatic gripper, etc.

The "AE-PLC-ALV" is an independent workstation that can work alone and/or in conjunction with other workstation to make up a complete Flexible Manufacturing System*.

*The Flexible manufacturing systems product list is available at the "6.-MECHATRONICS, AUTOMATION AND COMPUMECHATRONICS" area.

The pneumatic circuit and the workstation are distributed in the following sections:

- Air Treatment System: it contains a filter-regulator block with a water trap and shut-off valve to control the air pressure input to the unit. Includes a dual-scale pressure gauge to visualize the pressure level supplied to the unit.

- Parts Feeding Station Section: contains a sloped ramp for supplying parts to the system. Parts are supplied to the unit one by one through a double-acting cylinder. Each of the two inputs of the double-acting cylinder has an adjustable airflow valve with a bypass to regulate the cylinder speed.

- Parts Displacement Section: designed to displace the verified parts to the sorting area. This action is carried out by a double-acting cylinder and a platform with a gantry moved by a DC motor. Each of the two inputs of the double-acting cylinder has an adjustable airflow valve with a bypass and a pilot-operated check valve to regulate the cylinder speed and block its position in case there is no air input in the double-acting cylinder.

- Parts Storage Section: designed to store the parts. The module records which locations are occupied and deposits it in the first available space. It is a pneumatic gripper that moves through two DC motors.

- Signaling Tower: contains green, yellow, and red LED lights to indicate the system's status.

- Solenoid Valve Block: is a distributor block of pneumatic valves with five solenoid valves, three of which function as 5/2 monostable solenoid valves and two as 5/2 bistable solenoid valves.

- Electrical Terminal Block: contains all accessible and identified unit signals for manual unit checking. The electrical terminal block has color-coded terminals to help the user identify the type of each signal, and it also contains the name of each signal.

Cookie preferences

Cookie preferences