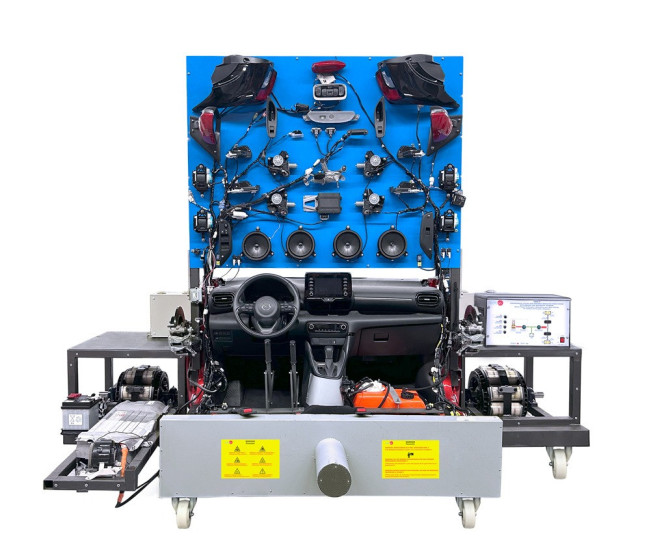

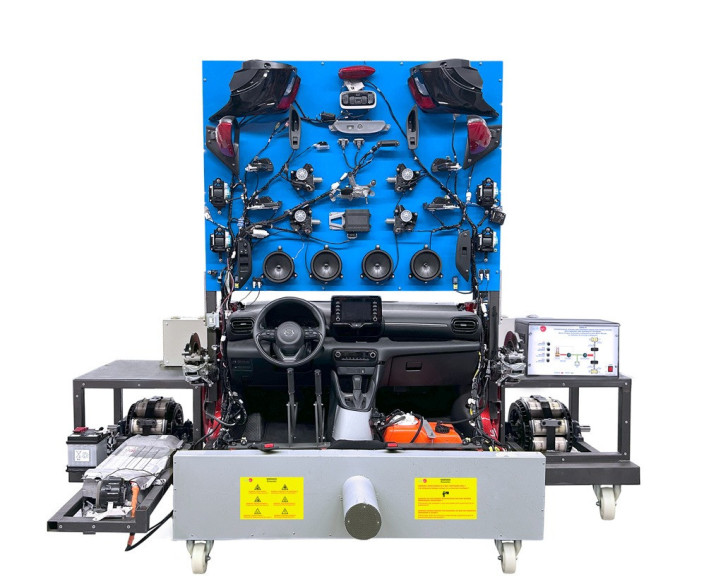

The Comprehensive Testing and Diagnosis Unit for Hybrid Engine with Braking and Diagnostic Software, "TBM/H", designed by EDIBON, is an advanced unit that enables an in-depth analysis of hybrid engine performance, providing a key solution for education in automotive engineering and sustainable mobility. Its design facilitates performance testing, evaluation of key components, and fault diagnostics, optimizing the efficiency and operation of these propulsion systems.

The unit is structured into three main sections, each designed to analyze and understand different systems of a hybrid vehicle under real operating conditions:

- Central control panel and cabin systems: Located in the center of the unit, the blue control panel houses key electrical components of the cabin, such as power windows, interior lights, seat belts, door locks, and windshield wipers. This design helps users understand the integration and functionality of electronic systems that contribute to vehicle safety and comfort.

- Driver and co-driver area: Located beneath the central panel, this section integrates the steering wheel, the accelerator and brake pedals, the gear shift, the instrument cluster, and the diagnostic system. This system connects to a computer, allowing for the monitoring of parameters and fault detection, facilitating precise analysis of the vehicle’s operation. On its right side are the glove compartment and fuel tank. On both sides of this section, you can find the parking brakes.

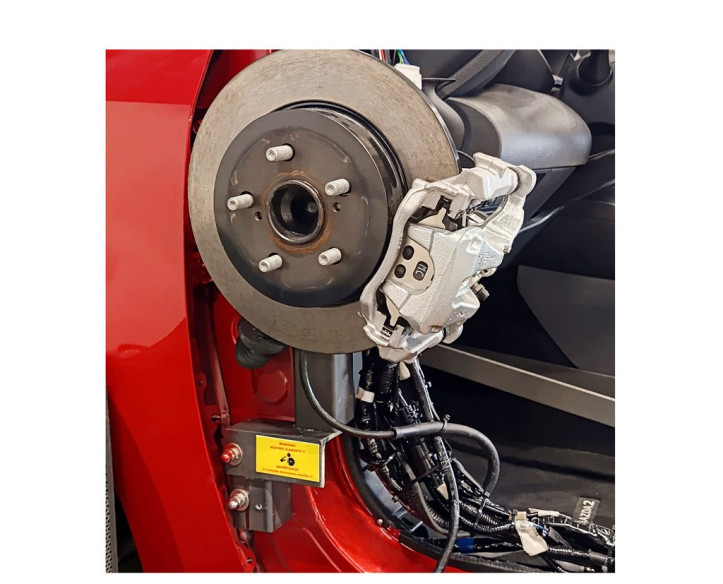

- Hybrid power system and load and braking simulation system: To the left of the central panel is the battery block, which consists of a 12V battery that supplies power to the combustion engine and a hybrid battery that powers the electric motor in certain operating modes. To prevent overheating, the unit includes a cooling fan, which activates automatically when the battery temperature exceeds a preset threshold, ensuring safe operation. On both sides of the unit, to simulate variations in vehicle load, an eddy current braking system has been integrated, generating resistance to wheel rotation, allowing the recreation of different driving scenarios. This system is adjustable via an interface located on the right side of the panel, enabling users to configure and analyze torque, wheel speed, acceleration, and engine power. Additionally, the brakes are connected to load cells, which measure real-time torque exerted by the engine, while speed sensors on the steering axle provide precise data on vehicle speed. This advanced instrumentation makes it possible to accurately evaluate power generation and hybrid system efficiency under various operating conditions.

This design allows for comprehensive testing in multiple driving scenarios, facilitating the analysis of hybrid engine performance and efficiency in a controlled environment. With its advanced instrumentation and simulation capabilities, the "TBM/H" becomes an essential unit for training engineers and technicians in automotive engineering, electronics, and mobility, providing in-depth knowledge of hybrid propulsion systems and their optimization.

クッキーの設定

クッキーの設定